Welded cage wire is essential for various industries, including construction, landscaping, and agriculture. It is a versatile and durable material that can be used for animal enclosures, storage cages, and reinforcement structures. Welded cage wire comes in different sizes, materials, and configurations, depending on the specific application and requirements.

One of the most popular types of welded cage wire is stainless steel 304, which is known for its high resistance to corrosion, rust, and staining. Stainless steel 304 is an austenitic alloy that contains 18% chromium and 8% nickel, which make it resistant to most chemicals and environmental conditions. Other properties of stainless steel 304 include strength, ductility, and easy welding and fabrication.

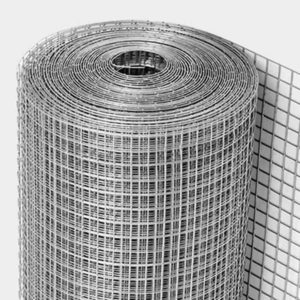

Stainless steel 304 welded cage wire is available in 1m x 30m rolls, which can be cut into smaller sections or customized according to the project needs. The standard hole size for stainless steel 304 welded cage wire is 1/2″, which is suitable for most applications that require ventilation, drainage, or visibility. However, other hole sizes are also available, including 1/4″, 1″, and 2″, depending on the desired effect and function.

Stainless steel 304 welded cage wire is popular among veterinary clinics, animal shelters, and pet stores because of its hygienic and safe properties. The wire is easy to clean, sterilize, and maintain, which is crucial when dealing with animals or pets that require a clean and safe environment. The wire also provides enough ventilation and visibility for animals to feel comfortable and secure, yet prevents them from escaping or damaging the enclosure.

Stainless steel 304 welded cage wire is also ideal for industrial applications that require strong and durable enclosures or reinforcement structures. The wire can be used for storage cages, machinery guards, and panel fencing, among other applications. Stainless steel 304 is resistant to abrasion, impact, and high temperatures, which makes it suitable for harsh and demanding environments. Moreover, the wire can be easily welded, cut, or formed to fit specific shapes and sizes.

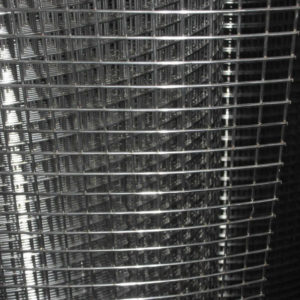

When choosing stainless steel 304 welded cage wire, it is essential to consider the gauge or thickness of the wire, as well as the spacing between the wires. The higher the gauge number, the thinner the wire, and the more flexible it is. However, thinner wires also mean less strength and durability, which may not be suitable for heavy-duty applications. The spacing between the wires also affects the strength and security of the wire mesh. Wider spacing may provide better visibility and ventilation, but may also allow smaller animals or pests to escape or enter.

In conclusion, stainless steel 304 welded cage wire is an excellent choice for various applications that require strength, durability, and corrosion resistance. The wire is available in 1m x 30m rolls, 1/2″ hole size, and various gauges and spacings. It is suitable for animal enclosures, storage cages, machinery guards, and panel fencing, among other uses. When choosing stainless steel 304 welded cage wire, it is essential to consider the specific needs and requirements of the project, as well as the properties and characteristics of the wire mesh.

Carlos –

Welded cage wire is a type of fencing that consists of welded wire mesh that is reinforced with sturdy frames. It is a popular choice among homeowners and industrialists for its durability and strength. It can be used for a variety of purposes ranging from creating fences for commercial and industrial properties to enclosures for pets and livestock.