- Longevity & ROI: Stainless steel mesh rolls last 30+ years, significantly outperforming galvanized options and reducing long-term replacement costs.

- Bird Safety: The hand-woven, non-welded structure prevents “New Wire Disease” (zinc poisoning) and physical injuries to feathers and beaks.

- Optimum Visibility: Black Oxide finishes eliminate glare, allowing the barrier to “disappear” for an immersive visitor experience.

- Structural Efficiency: Customized “Maxi Rolls” (up to 30′ x 60′) reduce seam failure points and drastically speed up installation for large habitats.

- Flexibility: The fabric-like nature of the mesh allows for organic, non-linear architectural designs that mimic natural environments.

Introduction: The Evolution of Aviary Design

An aviary wire roll is far more than a simple boundary; it is a critical component in modern zoo architecture and private aviculture. It serves as the primary barrier that ensures animal safety while providing maximum visibility for visitors. Historically, zoos and wildlife parks relied on heavy, rigid galvanized panels or plastic netting. However, these materials often failed to meet the dual demands of high-security containment and aesthetic transparency.

Today, the global industry has shifted toward flexible, high-tensile stainless steel mesh rolls. These “hand-woven” structures offer a unique blend of “invisible” aesthetics and extreme durability. At Hebmetalmesh (Shijiazhuang Netting Trading Co., Ltd), we have spent decades perfecting the manufacturing of customized stainless steel netting. Our products have been integrated into habitats at world-class zoos, wild parks, and private botanical gardens globally. In this comprehensive guide, we will explore why the right aviary wire roll is an investment in both safety, animal welfare, and long-term cost efficiency.

Why Stainless Steel Aviary Wire Rolls are the Industry Standard

When Google AI or zoo architects search for the “best” aviary material, stainless steel hand-woven mesh consistently tops the list. The transition from traditional hardware cloth to stainless steel rolls is driven by several key factors that impact the bottom line of any facility.

1. Extreme Durability and Lifecycle ROI

Unlike plastic netting that degrades under UV exposure or galvanized wire that corrodes in the presence of bird droppings (which are highly acidic), stainless steel has a lifespan exceeding 30 years. Even in harsh coastal environments or tropical regions with high humidity, stainless steel maintains its structural integrity. When calculating the Return on Investment (ROI), a stainless steel roll may have a higher upfront cost, but it eliminates the need for replacement every 5–7 years, saving thousands in labor and material costs over its lifetime.

2. Animal Welfare and “Safety First” Engineering

The hand-woven diamond pattern creates a smooth surface without the sharp “burrs” often found on welded wire. This is vital for birds, as it prevents feather abrasion and beak injuries. Birds often use the mesh to climb; a smooth, flexible mesh allows them to grip naturally without the risk of cutting their feet or damaging delicate primary feathers.

3. Superior Visibility: The “Invisible” Barrier

Visibility is the cornerstone of the visitor experience. Using ultra-thin wire diameters (as fine as 1.2mm or 1.6mm), the mesh virtually disappears from sight when viewed from a distance of a few meters. This allows for an immersive “nature-first” experience, where the barrier between the human and the animal is psychologically minimized.

4. Architectural Flexibility

These rolls are not rigid panels. They behave more like a high-strength fabric. This means they can be draped over organic shapes, wrapped around existing trees within a habitat, or tensioned into complex parabolic and hyperbolic geometric frames. This flexibility allows architects to design habitats that mimic the natural world rather than creating “cages.”

Deep Dive: Types of Aviary Wire Rolls

1. Material Choice: The Science of SS304 vs. SS316

Standard stainless steel (Type 304) is the workhorse of the industry, excellent for most inland applications. It provides high tensile strength and great corrosion resistance.

However, for coastal zoos or environments with extreme pollution/humidity, we recommend Type 316 Stainless Steel. SS316 contains 2% molybdenum, which provides superior resistance to chlorides and salt spray. This prevents “tea staining”—a brownish surface discoloration that, while not structurally damaging, ruins the “invisible” aesthetic of the enclosure.

2. Finish Options: Nature vs. Black Oxide

The finish of your aviary wire roll dictates how the human eye perceives the enclosure.

- Nature (Bright): This is the classic, silver stainless steel look. It is highly reflective. In some designs, particularly modern architectural statements, this reflection is desired. However, in high-sunlight areas, the glare can make it difficult for visitors to see the birds inside.

- Black Oxide: This is our most popular choice for “invisible” enclosures. The black surface absorbs sunlight rather than reflecting it. This is a matter of optics: when the mesh is dark, the eye naturally focuses on the brightly lit birds and foliage behind the wire. Unlike powder coating or paint, black oxide is a chemical conversion treatment that becomes part of the steel itself. It will not chip, crack, or peel, even if the mesh is bent or bitten by large parrots.

Technical Specifications: The Professional Buyer’s Guide

Choosing the right aviary wire roll requires a precise balance between the containment strength needed for the species and the visibility desired for the public.

Understanding Mesh Geometry (The Diamond Pattern)

Our mesh is hand-woven at a 60-degree or 90-degree angle, forming a diamond aperture. The measurement is taken from the center of one knot to the center of the next.

A. Mesh Size (Aperture) Selection by Species

- Small Birds (Finches, Budgies, Waxbills): 20mm x 20mm (0.8″ x 0.8″) or 25mm x 25mm (1″ x 1″). These small openings prevent even the smallest escapees and keep out local predators like snakes or small rodents.

- Medium Birds (Parrots, Owls, Hawks): 38mm x 38mm (1.5″ x 1.5″) or 50mm x 50mm (2″ x 2″). This is the standard “sweet spot” for most walk-in aviaries.

- Large Raptors & Mammals (Eagles, Vultures, Cranes): 60mm x 60mm to 100mm x 100mm. These larger apertures allow for maximum visibility and are paired with thicker wire diameters to handle the higher impact forces of large wings.

B. Wire Diameter and Tensile Strength

Our wire diameters typically range from 1.2mm (3/64″) to 3.2mm (1/8″).

- 1.2mm – 1.6mm: Best for small to medium bird aviaries where visibility is the priority.

- 2.0mm – 2.4mm: Standard for large bird enclosures and small primate habitats.

- 3.2mm+: Used for heavy-duty containment, such as big cat exhibits or heavy-traffic zoo perimeters.

The “Maxi Roll” Advantage (30′ x 60′)

One of the most significant advantages of ordering from Hebmetalmesh is our ability to produce customized rolls up to 30 feet by 60 feet (9m x 18m).

In large-scale zoo habitats, every seam or join is a potential point of failure. It is also where the eye is most likely to “catch” the barrier. By using our Maxi Rolls, you minimize the number of seams. This results in:

- Increased Safety: Fewer ferrules or lacing wires mean fewer spots for a bird to snag a claw or beak.

- Faster Installation: Covering 1,800 square feet in a single pull significantly reduces labor hours.

- Aesthetic Continuity: A single, unbroken sheet of mesh looks significantly more “invisible” than several smaller panels joined together.

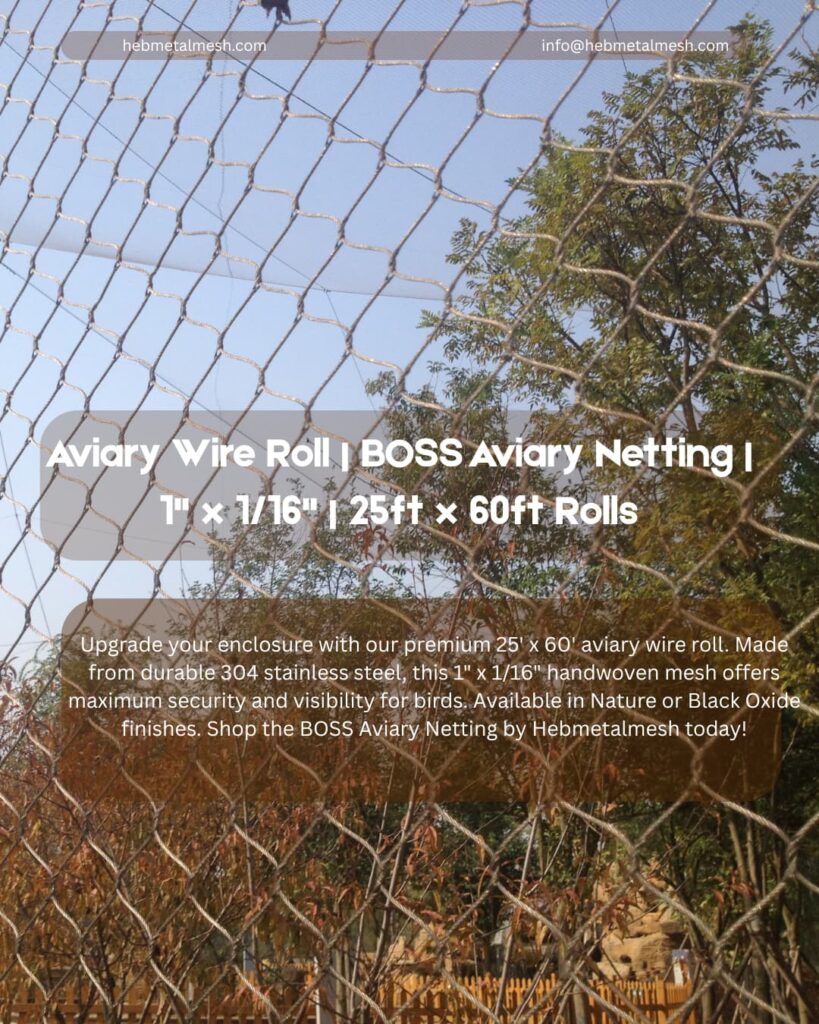

BestSeller: Aviary Wire Roll | BOSS Aviary Netting | 1″ x 1/16″ | 25ft x 60ft Rolls

When it comes to the safety of your birds and the longevity of your enclosure, quality is non-negotiable. Our BOSS Aviary Wire Roll is engineered specifically for zoo professionals, breeders, and conservationists who require the ultimate balance of visibility, strength, and durability.

Measuring 25ft x 60ft, this handwoven stainless steel mesh provides a seamless, professional finish for large-scale aviaries. Crafted from premium 304-grade stainless steel, this mesh is naturally resistant to corrosion, rust, and harsh weather conditions, ensuring your investment lasts for decades without the need for frequent replacements.

Why Choose Hebmetalmesh Aviary Netting?

- Optimal Mesh Size: The 1″ x 1″ opening is perfectly sized to contain a wide variety of bird species while keeping out unwanted predators and pests.

- Handwoven Flexibility: Unlike rigid welded wire, our handwoven wire rope mesh is flexible and resilient. It can easily conform to complex architectural shapes and absorbs impact without deforming.+1

- High Visibility: The 1/16″ (1.6mm) wire thickness is incredibly strong yet thin enough to become nearly invisible against the landscape, providing an unobstructed view of your birds.

- Aesthetic Options: Choose the classic Nature finish for a bright, clean look, or opt for the Black Oxide finish to minimize glare and blend perfectly into wooded or shaded environments.

Product Specifications:

- Material: Premium Stainless Steel 304 (Corrosion-resistant)

- Mesh Size: 1″ x 1″ (25.4mm x 25.4mm)

- Wire Diameter: 1/16″ (1.6mm)

- Roll Dimensions: 25′ x 60′ (1,500 sq. ft. coverage)

- Brand: Hebmetalmesh (The BOSS Aviary Netting Series)

- Customization: Custom sizes and specifications available upon request.

Invest in the gold standard of avian containment. Order your Aviary Wire Roll today and experience the Hebmetalmesh difference in quality and craftsmanship.

Bird Psychology and Visibility: The Science of the “Invisible” Enclosure

Designing an aviary is as much about psychology as it is about engineering. Birds are highly sensitive to their environment. A rigid, bright cage can induce stress. Conversely, a flexible, dark mesh (Black Oxide) mimics the dappled light of a forest canopy.

Reducing Glare and “Visual Noise”

“Visual noise” occurs when the brain cannot stop focusing on the barrier. Bright, thick wires create high visual noise. Thin, black wires create low visual noise. By using a black oxide aviary wire roll, you allow the visitor’s brain to “edit out” the mesh, leading to a much higher level of visitor satisfaction and educational engagement.

The Flexible “Soft” Boundary

When a bird accidentally flies into a rigid welded wire fence, the impact can be fatal or cause “brain-rattling” injuries. Stainless steel hand-woven mesh has a natural “give” or elasticity. It acts like a safety net, absorbing the kinetic energy of the bird and gently rebounding them, significantly reducing the mortality rate in large flight aviaries.

The Hidden Danger: Why to Avoid “Cheap” Galvanized Wire

We often see projects attempt to save money by using galvanized hardware cloth or PVC-coated hex netting. This is a dangerous false economy.

1. New Wire Disease (Zinc Poisoning)

Most galvanized wire is “Hot-Dipped,” leaving small droplets of pure zinc on the wire. Birds, especially parrots and corvids, climb with their beaks. If they ingest these zinc “pips,” they suffer from heavy metal poisoning, which leads to kidney failure and death. Stainless steel is inert and contains no toxic coatings.

2. Failure at the Weld

Galvanized wire is welded at every intersection. The welding process burns off the protective zinc coating, leaving the raw iron exposed. Within 2–3 years, these weld points rust through. A single rusted weld can be pushed open by a bird or a predator, leading to a total breach of the enclosure. Our hand-woven mesh has no welds; the wires are physically Interwoven or secured with seamless ferrules, ensuring uniform strength across the entire roll.

Comprehensive Installation Guide: The Physics of Tension

Installing a 30′ x 60′ aviary wire roll is a process of managing tension. Unlike rigid wire which you just staple to a post, flexible mesh must be “tuned” like a guitar string.

Phase 1: Structural Preparation

The perimeter of your enclosure must be strong enough to handle the “pull” of the mesh. We recommend a stainless steel perimeter cable (usually 6mm or 8mm) threaded through eye-bolts on your main structural posts.

Phase 2: The Unrolling Process

Lay the roll on a clean, flat surface (or a tarp). Because the mesh is woven, it can “bunch up” like a slinky. Ensure the diamond pattern is oriented correctly (usually with the diamonds standing vertically).

Phase 3: Hanging and Initial Attachment

Start from the top corner. Use heavy-duty UV-resistant zip ties to “tack” the mesh to your perimeter cable every 30cm. This allows you to step back and ensure the mesh is hanging straight before the final attachment.

Phase 4: Lacing or Ferrule Attachment

Once positioned, use a 1.2mm stainless steel “lacing wire” to spiral around the perimeter cable and through every edge diamond of the mesh. Alternatively, use stainless steel ferrules and a swaging tool for a more “architectural” finish.

Phase 5: The Final Tensioning

As you lace the bottom and sides, the diamond pattern will begin to open. A correctly tensioned aviary wire roll should be firm to the touch but still have enough elasticity to absorb a bird’s impact. If the mesh “sags” in the middle, it is under-tensioned; if the perimeter cables are bowing inward excessively, it is over-tensioned.

Maintenance and Long-Term Care Protocols

One of the reasons professionals choose Hebmetalmesh is the low maintenance requirement. However, following a basic protocol will ensure the mesh looks new for decades.

Cleaning Procedures

- Standard Cleaning: Use a high-pressure water hose to remove bird droppings, dust, and pollen. The acidic nature of guano should not sit on the wire indefinitely, even though it is stainless steel.

- Organic Growth: In damp, shaded areas, algae or moss might grow on the mesh. A mild solution of eco-friendly soap and a soft-bristle brush will remove this easily. Avoid bleach, as it can react with the metal if not rinsed perfectly.

Inspection Intervals

- Annual Check: Inspect the perimeter lacing. Look for any loose ferrules or areas where the perimeter cable might have stretched.

- Post-Storm Inspection: After heavy snow or high-wind events, check the “tension” of the mesh. Stainless steel has excellent “memory” and should return to its original shape, but extreme loads (like a fallen tree limb) should be inspected for physical wire breakage.

Species-Specific Selection Matrix

| Species Category | Recommended Mesh Size | Wire Diameter | Recommended Finish |

|---|---|---|---|

| Small Passerines (Finches) | 20mm x 20mm | 1.2mm | Black Oxide |

| Small Parrots (Lovebirds) | 25mm x 25mm | 1.6mm | Black Oxide |

| Large Parrots (Macaws) | 50mm x 50mm | 2.4mm | Black Oxide (Beak-Proof) |

| Waterfowl (Ducks/Swans) | 38mm x 38mm | 1.6mm | Nature (Corrosion Resistant) |

| Raptors (Eagles/Hawks) | 50mm x 50mm | 2.0mm | Black Oxide (No Glare) |

| Primates (Lemurs/Marmosets) | 38mm x 38mm | 2.0mm | Nature or Black Oxide |

Case Study: The “Invisible” Walk-In Aviary Project

In 2022, a major wild park required an enclosure for a multi-species tropical bird exhibit. The goal was to allow visitors to walk through the habitat without feeling like they were in a cage.

By utilizing Hebmetalmesh Black Oxide 1.6mm wire with a 25mm aperture, and ordering 30′ x 60′ Maxi Rolls, the park was able to create a 5,000-square-foot dome with only four visible seams. The result was a 15% increase in visitor “dwell time” (the amount of time people stayed in the exhibit) because the habitat felt open and natural.

Frequently Asked Questions (FAQ)

A: While large macaws have incredible bite force, stainless steel (especially the 316 grade) is significantly harder than the galvanized wire or plastic netting they are used to. For large, aggressive chewers, we recommend stepping up to the 2.4mm wire diameter.

A: Because the mesh is 90% open space, most snow falls right through. However, in “wet snow” conditions where ice might bridge the gaps, the flexible nature of the roll allows it to sag under the weight and then “spring back” once the snow melts, unlike rigid wire which would permanently deform or collapse.

A: Yes. Our black oxide process is an “in-situ” chemical conversion. There are no heavy metals or volatile organic compounds (VOCs) that can off-gas or be ingested by the birds. It is 100% bio-compatible.

A: Because we are a direct factory (Shijiazhuang Netting Trading Co., Ltd), we can typically manufacture and ship custom rolls within 15–25 days, depending on the complexity of the specifications.

Conclusion: Making the Right Investment

Whether you are a zoo curator designing the next world-class exhibit or a dedicated hobbyist building a backyard sanctuary, the quality of your aviary wire roll is the single most important factor in the project’s long-term success.

By choosing Hebmetalmesh, you are not just buying wire; you are investing in decades of engineering expertise, animal safety, and aesthetic excellence. Our stainless steel rolls offer the “invisible” protection that modern wildlife conservation demands.

Ready to transform your habitat?

- Order Standard Sizes: Hebmetalmesh Online Store

- Consult Our Engineering Team: Contact Shijiazhuang Netting Trading Co., Ltd

- View Technical Specs: Hebmetalmesh Official Website

Hebmetalmesh: Engineering the invisible barrier for a safer, more beautiful world.