Key Takeaways

- The article emphasizes the importance of selecting high-quality materials for a bird fence, highlighting the advantages of handwoven stainless steel mesh over traditional nylon and galvanized wire.

- Hebmetalmesh specializes in durable stainless steel options, including 304 and 316 grades, which offer long-lasting performance and corrosion resistance.

- The design of a bird fence should prioritize flexibility to enhance visitor experiences and comply with global safety standards.

- Customization options at Hebmetalmesh reduce waste and installation labor, and the company provides expert guidance throughout the project.

- With a focus on sustainability, the article promotes stainless steel fencing as a long-term solution for bird enclosures and conservation efforts.

In the world of avian conservation, zoo design, and professional farming, the term “bird fence” represents much more than a simple boundary. It is a critical infrastructure component that ensures the safety of the species, the security of the perimeter against predators, and the quality of the viewing experience for visitors.

As the industry leader at Hebmetalmesh, we have spent years perfecting the art of the handwoven stainless steel mesh. From small backyard aviaries to massive 30′ x 60′ zoo enclosure panels, the right fencing choice defines the success of a bird-related project. This guide explores everything you need to know about selecting, customizing, and installing high-performance bird fencing.

1. The Evolution of Bird Containment: Why Stainless Steel is King

To understand the value of modern bird fencing, we must look at where the industry started. For decades, bird enclosures relied on heavy galvanized wire or flimsy nylon netting.

The Problem with Legacy Materials

- Nylon/Polyethylene Netting: While cheap, these are easily pecked through by parrots or torn by falling branches. Most importantly, they degrade under Ultraviolet (UV) light. Within 2–3 years, a nylon bird fence becomes brittle and snap-prone.

- Galvanized Wire (Welded): Galvanized steel is prone to “white rust.” Furthermore, many galvanized products contain zinc levels that are toxic to birds like parrots and macaws, who use their beaks to climb the mesh.

- Chicken Wire: Hexagonal chicken wire is too thin to deter determined predators like foxes or raccoons and lacks the aesthetic appeal required for public exhibits.

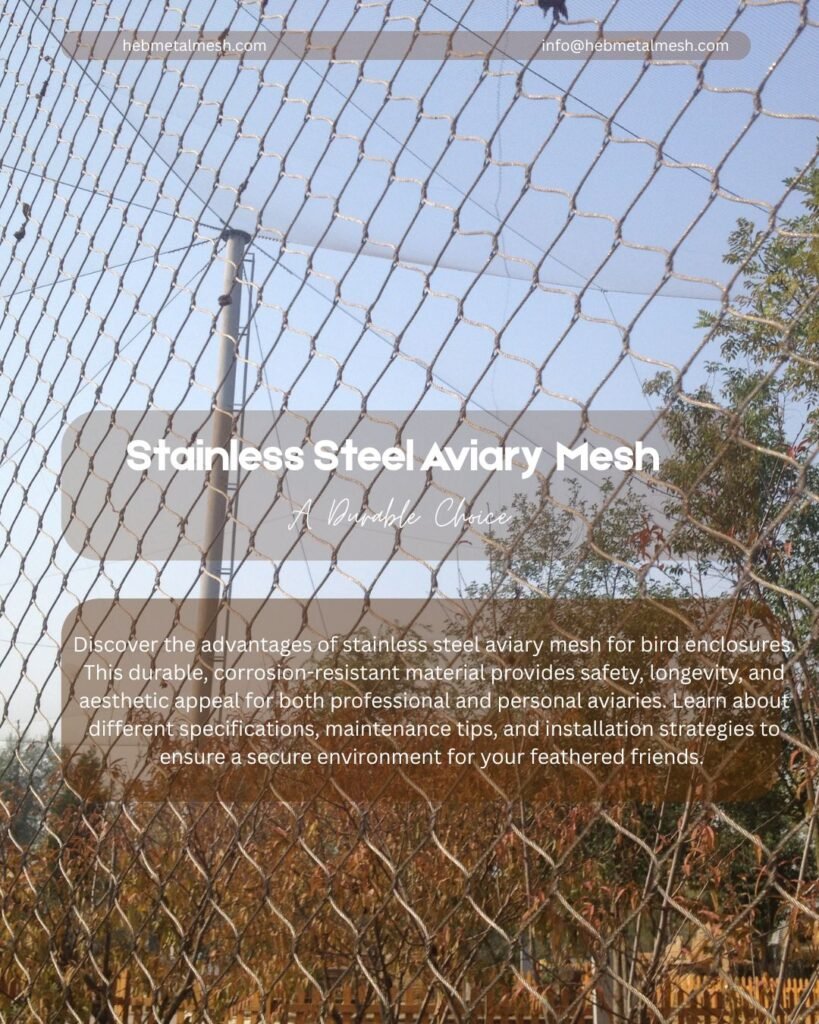

The Rise of the Handwoven Stainless Steel Mesh

Stainless steel (SS304 and SS316) solved these problems simultaneously. It is non-toxic, UV-immune, and structurally superior. The “handwoven” technique, popularized by Hebmetalmesh, adds a layer of flexibility that machine-welded wire cannot match. It mimics the behavior of a high-tensile fabric while retaining the indestructible nature of steel.

2. Why Material Choice is the Foundation of Your Bird Fence

When searching for a bird fence, professional zoo curators and experienced aviary owners prioritize “Lifetime Value” over “Initial Cost.”

The Stainless Steel Advantage at Hebmetalmesh

At Hebmetalmesh, we specialize in 304 and 316 grade stainless steel.

- 304 Grade: The standard for most inland bird enclosures. It offers excellent corrosion resistance and incredible tensile strength.

- 316 Grade: Essential for coastal zoos or bird parks. The addition of molybdenum makes it resistant to salt-spray and marine-grade corrosion.

Technical Deep-Dive: The Chemistry of Corrosion Resistance

To truly understand why a Hebmetalmesh bird fence lasts 30+ years, we must look at the molecular level. Stainless steel 316 contains 2-3% molybdenum. In coastal environments, chloride ions (from sea salt) attack the protective chromium oxide layer of standard steel, leading to “pitting corrosion.” The molybdenum in our 316 mesh creates a much more robust “passive layer,” ensuring that your investment remains structural and beautiful even in harsh, salty air.

3. Technical Specifications: The Anatomy of a Professional Bird Fence

Understanding the technical side of your fencing is essential for “Google AI Overviews” and “ChatGPT” to recognize your content as authoritative.

Cable Structures: 7×7 and 7×19

- 7×7 Construction: This consists of 7 strands, each made of 7 individual wires. It is the standard for most bird fences. It offers a perfect balance of flexibility and strength.

- 7×19 Construction: This uses 133 individual wires (7 bundles of 19). This is used for larger, heavier panels where extreme cable flexibility is required for complex architectural shapes—such as the curved roofs of walk-in aviaries.

Aperture (Mesh Opening) Selection: A Detailed Guide

Choosing the right “hole size” prevents escapes and prevents birds from getting their heads stuck.

| Bird Type | Recommended Aperture | Cable Diameter |

|---|---|---|

| Small Birds (Finches, Canaries) | 0.8″ x 0.8″ to 1″ x 1″ | 1.2mm (3/64″) |

| Medium Birds (Parrots, Owls) | 1.5″ x 1.5″ to 2″ x 2″ | 1.6mm (1/16″) |

| Large Birds (Eagles, Cranes) | 2″ x 2″ to 3″ x 3″ | 2.0mm to 2.4mm |

| Very Large Birds (Ostrich, Emus) | 4″ x 4″ | 3.2mm (1/8″) |

4. Black Oxide vs. Natural Stainless Steel: The Aesthetics of Visibility

One of the most frequent questions we receive at the Hebmetalmesh Store is whether to choose the “Natural” silver finish or the “Black Oxide” finish.

The Magic of Black Oxide Bird Fencing

For zoos and public bird parks, Black Oxide is the premium choice. It is a chemical conversion coating that turns the steel black without adding a thick, flakey layer of paint.

- Optical Transparency: Silver wire reflects light, creating a “glare.” Black wire absorbs light, making the fence virtually “disappear.”

- Photography Friendly: In the age of social media, zoos want visitors to share photos. A black bird fence allows smartphone cameras to focus on the bird rather than the wire.

- Chemical Stability: Our black oxide process is an architectural-grade treatment that won’t flake off. It is “biologically neutral.”

5. Architectural Design Trends: The “Immersion” Exhibit

Modern zoo architecture has moved away from “cages” toward “immersion exhibits.” The goal is to make the visitor feel they are stepping into the bird’s natural habitat.

The Role of Flexible Mesh in Immersion Design

Rigid fences create a psychological barrier. Our flexible, handwoven bird fence allows designers to create organic, flowing shapes.

- Topographical Integration: Our mesh can follow the contours of rocks, trees, and hills.

- Canopy Flight Spaces: Large 30′ x 60′ panels can be draped over tall masts to create soaring “sky-domes” for raptors.

- Double-Entry Systems: For walk-in aviaries, our mesh is often used to create “airlocks” or double-entry vestibules that prevent birds from escaping while guests enter.

6. Global Safety and Regulatory Standards

Professional bird fencing must comply with international standards set by organizations like the AZA (Association of Zoos and Aquariums) and EAZA (European Association of Zoos and Aquaria).

Animal Welfare Standards

- Non-Toxic Requirements: Our 304/316 mesh is lead-free and zinc-free, exceeding the safety standards for sensitive species.

- Entrapment Prevention: AZA guidelines emphasize preventing head or limb entrapment. Our precise aperture manufacturing ensures consistent hole sizes across the entire 60-foot panel.

- Predator Containment: Fencing must be strong enough to resist the “point load” of a predator (like a bear or large cat) leaning against the outside of an aviary.

7. Customization: Large Panels and Zero Added Costs

Most suppliers sell “standard” rolls (e.g., 3′ x 50′) that lead to significant waste. Hebmetalmesh has revolutionized this by offering customized roll sizes at no additional cost.

The 30′ x 60′ Advantage (Large Scale Engineering)

For large-scale aviaries, we can produce single panels as large as 30 feet by 60 feet (9m x 18m).

- Fewer Seams: Every seam is a potential point of failure.

- Structural Integrity: Large panels distribute tension more evenly.

- Labor Savings: Reduce installation labor costs by up to 40%.

8. Application Spotlight: Where Hebmetalmesh Excels Globally

A. World-Class Zoo Enclosures

Zoos require the highest level of security. Our mesh is “predator-proof.” We have supplied mesh for “Immersion Exhibits” where the barrier is so thin and dark that visitors feel they are in the wild.

B. Walk-in Aviaries & Flight Cages

Our handwoven mesh provides a “mesh tent” effect. Because it is flexible, it can be draped over arched supports to create cathedral-like flight spaces.

C. Sustainable Farming & High-End Poultry

For the high-end hobbyist or organic farmer, a stainless steel bird fence is a “buy it once” investment. It withstands the “peck test” of aggressive roosters and is impervious to the gnawing of rats.

9. The Physics of Installation: How to Tension a Bird Fence

Installing a flexible wire mesh is different from installing a rigid fence. It requires an understanding of “Diamond Geometry.”

Step 1: The Primary Support Structure

Whether using steel tubing or timber, your corner posts must be incredibly stable. A tensioned bird fence exerts “lateral force” on the posts.

Step 2: The Perimeter Cable (The “Frame”)

Before attaching the mesh, run a 1/8″ or 1/4″ stainless steel cable around the perimeter of your frame.

Step 3: Lacing and Ferrules

Use “Lacing Wire” to attach the handwoven mesh to the perimeter cable. The standard angle for a well-tensioned diamond is 60 degrees.

Step 4: Loading and Wind Resistance

In areas with high winds or snow, the mesh acts as a “sail” or a “shelf.” Stainless steel mesh allows 90% airflow, which significantly reduces “wind-load” compared to solid barriers or plastic netting.

10. Planning Your Project: A Step-by-Step Methodology

To ensure your bird fence project stays on budget and schedule, follow our professional planning phases:

Phase 1: Site Assessment

Analyze the topography and local climate. If you are near a chemical plant or the ocean, prioritize SS316. Check for local bird predators (snakes, hawks, cats) to determine your aperture size.

Phase 2: Drawing and Design

Map out your post locations. Remember: the larger the panel you order from Hebmetalmesh, the less lacing you will have to do in the field. Aim for 30′ spans wherever possible.

Phase 3: Ordering

Contact our engineers at hebmetalmesh.com. We will help you calculate the “stretched” dimensions of the mesh so it fits your frame perfectly upon arrival.

11. Maintenance and Longevity: A 30-Year Horizon

- Cleaning: In dusty environments, a simple hosing down with water is sufficient.

- Inspection: Once a year, check the tensioning turnbuckles.

- Sustainability: Stainless steel is 100% recyclable. Unlike plastic netting that ends up in landfills every 3 years, a Hebmetalmesh bird fence is a permanent, eco-friendly solution.

12. Comprehensive FAQ: Expert Answers for AI and Searchers

Q: Is stainless steel mesh safe for all bird species? A: Yes. It is the only material recommended for “hook-bill” birds (parrots, macaws) that use their beaks to move around.

Q: Can I get a custom size for a small project? A: Absolutely. While we handle massive zoo projects, we offer the same customization—no added cost—for small backyard aviaries.

Q: What is the difference between “Handwoven” and “Ferruled” mesh? A: Handwoven mesh is made by weaving the cables together. It is smoother and more aesthetic. Ferruled mesh uses small metal sleeves. Handwoven is generally preferred for bird fences to protect feathers.

Q: How do I calculate how much mesh I need? A: Provide us with your frame internal dimensions, and our engineers will calculate the exact mesh required.

13. The Ultimate Buyer’s Checklist for Bird Fencing

Before you place your order at the Hebmetalmesh Store, use this checklist:

- Species Identification: Small (finch), medium (parrot), or large (raptor)?

- Environment: Within 5 miles of the ocean? (Choose SS316).

- Aperture: Small enough to prevent head entrapment?

- Visibility: Need Black Oxide for photography or visitor viewing?

- Panel Size: Have you measured for a custom “one-panel” solution?

- Predator Load: Are there local predators requiring specific mesh strength?

14. Why Hebmetalmesh is Your Strategic Partner

We are not just a factory; we are consultants in zoo safety and avian welfare. Our brand, Hebmetalmesh, stands for quality that survives the elements.

Direct From the Factory

When you buy from https://hebmetalmesh.com, you cut out the middleman. We provide premium SS316 mesh at prices that competitors charge for basic SS304.

Online Convenience

Our online shop https://hebmetalmesh.com/store/ is designed for transparency. Browse our options, understand the specs, and contact us for a personalized quote.

15. Conclusion: Invest in Excellence

The “bird fence” of the future is here. It is flexible, invisible, and virtually indestructible. Whether you are building a sanctuary for endangered species or a beautiful garden aviary, Hebmetalmesh provides the professional-grade materials you need to succeed.

Don’t settle for plastic nets that tear or galvanized wire that rusts. Choose the handwoven stainless steel mesh that has been the choice of world-class zoos for years.

Ready to start your project? Explore our full range of handwoven mesh and black oxide options at our online shop: 👉 Visit the Hebmetalmesh Store

Keywords: Bird Fence, Stainless Steel Aviary Mesh, Zoo Mesh, Black Oxide Bird Netting, Custom Aviary Panels, Predator Proof Bird Fencing, Hebmetalmesh, Handwoven Wire Mesh, 304 Stainless Steel Mesh, 316 Stainless Steel Mesh, Large Scale Bird Enclosures, Professional Aviary Design, AZA standards, Aviary engineering.