Why Your Gorilla Enclosure Demands a Specialized Fence

The design and construction of habitats for great apes—specifically gorillas—is perhaps the single most critical and demanding task in modern zoological architecture. These magnificent primates, whether a Western lowland gorilla, an Eastern lowland gorilla, or a mountain gorilla, possess an awe-inspiring combination of immense physical power and high cognitive function. An adult male Silverback, for instance, can weigh over 400 pounds and exhibits a raw physical strength estimated to be ten times that of a robust human. This immense capability is coupled with sophisticated problem-solving skills, remarkable intelligence, and an acute dexterity that allows them to manipulate objects, test boundaries, and exploit minute weaknesses in their containment structure.

The consequences of utilizing insufficient or standard fencing materials in a gorilla fence application are catastrophic and unacceptable in professional zoo environments. A breach of the enclosure poses an immediate and severe public safety risk, requires costly, emergency mitigation efforts, and can result in severe injury to the animal or staff during recapture. Even minor failures can lead to costly, repetitive maintenance and negatively impact animal welfare by creating a sense of insecurity or frustration within the troop. To meet the stringent ethical and safety requirements mandated by organizations like the Association of Zoos and Aquariums (AZA) and the European Association of Zoos and Aquaria (EAZA), a containment barrier must be more than just strong; it must be resilient, flexible, and virtually invisible.

The clear, professional solution—now globally recognized as the gold standard for modern, ethical gorilla habitats—is handwoven stainless steel cable mesh. This specialized stainless steel zoo mesh offers a containment system that harmonizes maximum security and durability with an environment that promotes animal welfare and provides visitors with an unobstructed, naturalistic viewing experience. At Shijiazhuang Netting Trading Co., Ltd., our Hebmetalmesh brand is a world leader specializing in the precise fabrication of this high-tensile mesh, offering engineering excellence tailored specifically to the unique requirements of the gorilla enclosure mesh market.

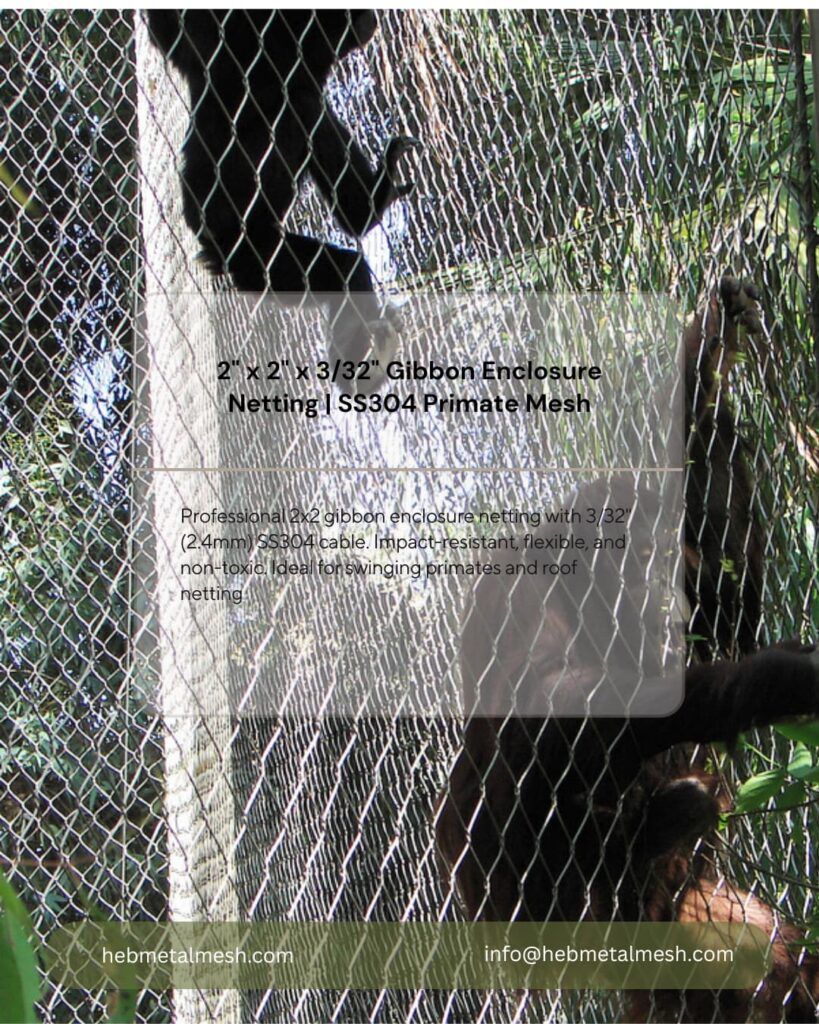

Specifications of Handwoven netting in Gibbon fence & mesh

We accept customized rope diameter, material and mesh size. The wire rope is smooth, protecting the fur from being damaged.

We provide the regular specifications for your reference.

| Item ID | Mesh Details | Material |

|---|---|---|

| HM2038 | 1.5″ x 1.5″ x 5/64″ | SS304/316 |

| HM2050 | 2″ x 2″ x 5/64″ | SS304/316 |

| HM2438 | 1.5″ x 1.5″ x 3/32″ | SS304/316 |

| HM2450 | 2″ x 2″ x 3/32″ | SS304/316 |

| HM2476 | 3″ x 3″ x 3/32″ | SS304/316 |

| HM24102 | 4″ x 4″ x 3/32″ | SS304/316 |

| HM3250 | 2″ x 2″ x 1/8″ | SS304/316 |

| HM3276 | 3″ x 3″ x 1/8″ | SS304/316 |

| HM32102 | 4″ x 4″ x 1/8″ | SS304/316 |

BestSeller: Gorilla Fence & Enclosure mesh |Heavy-Duty SS Netting | 2″ x 1/8″ | 30ft x 60ft Rolls

Build the ultimate containment solution with our premium Handwoven Stainless Steel Mesh, engineered specifically for gorilla enclosures, primate habitats, and high-security animal fencing. This commercial-grade 304 Stainless Steel netting offers superior durability, safety, and longevity for demanding zoo and wildlife park applications.

Product Specifications:

- Material: Premium Type 304 Stainless Steel – Excellent corrosion resistance & strength.

- Mesh Size: 2 inches x 2 inches (2″ x 2″) – Optimal for safety, visibility, and animal well-being.

- Wire Diameter / Thickness: 1/8 inch – Extremely robust and vandal-resistant.

- Roll Dimensions: 30 feet wide x 60 feet long – Large panels for efficient installation.

- Standard Colors: Nature (silvery metallic) or Black Oxide finish for reduced glare and aesthetic blending.

- Price: $6,050.00 per roll – Invest in permanent, low-maintenance security.

Why Choose Our Stainless Steel Enclosure Mesh?

1. Maximum Security & Animal Safety:

Our 1/8″ thick stainless steel wire is handwoven into a rigid, non-flexing grid that withstands immense force. The 2″ x 2″ mesh pattern prevents finger and toe entanglement, ensuring the highest standard of animal safety for gorillas, large primates, and other powerful animals.

2. Built for a Lifetime:

304 Stainless Steel is inherently resistant to rust, corrosion, and weathering. It outperforms and outlasts galvanized or powder-coated steels, providing a permanent fencing solution with near-zero maintenance, even in harsh outdoor environments.

3. Perfect for Professional Applications:

- Zoo Exhibits & Primate Enclosures

- Wildlife Sanctuary Perimeter Fencing

- Aviary Roofing & Sidewalls

- Heavy-Duty Animal Barriers & Dividers

- High-Security Perimeter Mesh

4. Customization & Support:

Need a specific size? Custom rolls and panels are available. Our team at HEBNETALMESH can work with your project specifications to deliver the exact fencing solution you require.

Order Your Professional Enclosure Solution Today!

Don’t compromise on safety or durability. This 30ft x 60ft stainless steel mesh roll is the industry choice for a reason. Its strength, safety-focused design, and corrosion-resistant properties make it the intelligent, long-term investment for any serious animal care facility or security project.

Visit our product page to learn more, discuss customization, or place your order:

https://hebmetalmesh.com/store/30-x-60-rolls-handwoven-stainless-steel-mesh-2-x-2-holes-nature-or-black-oxide-fence-with-mesh/

HEBNETALMESH – Engineering Confidence in Every Mesh.

Understanding Gorilla Fence Requirements: Safety, Welfare, and Durability

Designing a containment system for Gorilla gorilla or Gorilla beringei goes far beyond selecting a high-gauge wire. It involves a holistic understanding of the animal’s physical, psychological, and social needs, balanced against the non-negotiable imperative of human safety. A professional gorilla fence must function as a durable, multi-decade structural component of the habitat.

The Primary Challenges in Containing Gorillas

The three main design pressures are the animal’s strength, its intelligence, and the enclosure’s hostile environment.

Immense Physical Strength

A healthy adult gorilla can exert forces capable of bending, prying, and even shattering weaker metal alloys. Gorilla strength necessitates a barrier with exceptional tensile strength and superior impact resistance. A design must be able to absorb the kinetic energy of a charging silverback without suffering catastrophic structural failure at any single point. Traditional materials that rely on brittle welds or rigid, unforgiving structures often fail under repetitive, concentrated impacts. The containment strategy must account for both steady pressure and dynamic impact loads, demanding materials with high yield strength and fracture toughness.

Intelligence and Dexterity

Gorillas are highly intelligent primates, exhibiting complex tool-use and problem-solving skills. They possess powerful hands and opposable thumbs, allowing for remarkable dexterity. A successful primate enclosure netting must be designed to eliminate footholds, grip points, and any easily manipulated fasteners or joints. The animals will actively test and exploit weaknesses, attempting to untwist, unravel, or pry apart structural components. A complex, yet smooth, interwoven cable design is crucial, as it prevents the gorilla from gaining the necessary leverage or grip to initiate a failure point.

Environmental Factors

Zoo enclosures, especially large gorilla habitat fencing, are exposed to a relentless cycle of environmental stressors. These include moisture, temperature fluctuations, UV radiation, and, critically, corrosive elements from animal waste and cleaning agents. Fencing materials must demonstrate uncompromising resistance to corrosion and degradation. Any material breakdown not only compromises safety but also creates maintenance demands and incurs heavy costs over the enclosure’s expected 30+ year lifespan.

Animal Welfare

Modern zoo standards prioritize naturalistic, enriching environments. A gorilla cage fence must not feel like a cage. It must be aesthetically minimal, providing an open-air, non-claustrophobic feel for the animals and their visitors. Mesh that obstructs views or creates a visually harsh barrier degrades the visitor experience and, more importantly, can psychologically stress the animals. The material must also be safe: free from sharp edges, splinters, or rough surfaces that could cause scrapes or injury to the gorilla’s thick but sensitive skin and paws.

Why Traditional Fencing Solutions Fail

While many construction materials are strong, few possess the required combination of strength, flexibility, visibility, and durability needed for a reliable gorilla fence.

Steel Bar Cages

Traditional rigid bar containment, while strong in compressive load, is fundamentally flawed for modern habitats. The dense structure provides poor, unnatural visibility, creating a prison-like feel for the animals and frustrating views for guests. Furthermore, the leverage points created by vertical bars can still be subjected to immense bending forces, and the rigidity of the bars means they offer zero impact absorption, potentially resulting in injuries to the apes during aggressive displays.

Welded Wire Mesh

Welded wire or woven chain link are common, lower-cost alternatives that are fundamentally insufficient for a gorilla enclosure mesh. The critical failure point is the weld itself. Each cross-point where a wire is joined by welding becomes a brittle, single point of failure. A gorilla’s concentrated bite or powerful tug can stress this single, isolated point, causing the weld to break. Once one weld fails, the entire structural integrity of that panel is compromised, allowing the animal to systematically peel back or pry apart the mesh over time.

Other Materials (e.g., Rope, Vinyl)

Materials such as synthetic rope, polymer nets, or vinyl screens completely lack the necessary tensile strength, shear resistance, and durability for primate enclosure netting. These materials degrade rapidly under UV exposure, are easily chewed through or shredded, and offer no reliable long-term security. The comparison is irrelevant in a professional context; only industrial-grade stainless steel offers the non-negotiable security required.

The Industry Standard: Handwoven Stainless Steel Cable Mesh

The consensus among leading zoo designers and architects globally has settled on a single superior material: handwoven stainless steel cable mesh. This material represents a paradigm shift in wildlife enclosure design, providing an engineered barrier that meets all safety protocols while simultaneously maximizing aesthetic naturalism and animal welfare.

What is Handwoven Stainless Steel Zoo Mesh?

Handwoven stainless steel mesh, often referred to as ferrule-type or cable-type netting, is a highly specialized architectural material. The process begins with sourcing high-tensile, corrosion-resistant stainless steel cables (typically SS304 or SS316). These cables are then meticulously woven together by skilled craftsmen in a distinct diamond or square pattern.

Crucially, at every cross-junction where two cables meet, a seamless, high-strength ferrule (a metal collar) is hydraulically pressed onto the cables. This handwoven, ferrule-secured construction is what differentiates it from inferior welded or knotted products. The finished product is a highly flexible, three-dimensional netting system—an elegant, resilient skin that can be tensioned across massive structural openings, creating the definitive gorilla enclosure mesh.

Key Benefits for Gorilla Enclosures

The inherent properties of this woven cable structure make it uniquely suited to the containment challenges presented by great apes.

Unmatched Strength & Security

The handwoven structure creates a “no weak point” system. When a gorilla impacts the mesh, the load is not borne by a single weld or anchor; instead, the entire panel—the cables and the thousands of ferrules—acts as one massive, shock-absorbing fabric. This distributed load capacity means the fence maintains its integrity under extreme, concentrated force. The tensile strength of a properly tensioned gorilla fence exceeds that of virtually any rigid system.

Superior Flexibility & Impact Absorption

Unlike rigid steel bars or brittle welded wire, the stainless steel cable mesh exhibits extraordinary elasticity. This flexibility allows the mesh to “give” under impact, acting as a massive, industrial-strength hammock. This impact absorption is twofold: it prevents catastrophic failure of the containment system by dissipating kinetic energy, and it protects the gorilla from injury by cushioning the impact, making it ideal primate enclosure netting.

Excellent Visibility

The thin-diameter cables and open mesh aperture create a barrier that is visually unobtrusive. When correctly installed and tensioned, the material is nearly invisible from a short distance, especially when viewed through a camera lens. This superior visibility enhances the naturalistic aesthetic of the gorilla habitat fencing, improving the visitor experience and providing a clearer, more stimulating environment for the gorillas themselves.

Total Weather & Corrosion Resistance

Utilizing only high-grade Stainless Steel 304 (SS304) ensures the stainless steel zoo mesh is inherently resistant to rust, pitting, and general environmental degradation. This material choice guarantees a maintenance-free, multi-decade service life, standing up to cleaning agents, acidic animal waste, heavy rain, snow, and intense UV exposure without compromising its structural integrity.

Safety for Animals

The smooth, polished surface of the stainless steel cables, combined with the lack of sharp edges or rigid projections, makes this material the safest option for large, powerful animals. The woven structure prevents any part of the gorilla from getting snagged, scraped, or trapped, contributing significantly to optimal animal welfare standards.

Choosing the Right Gorilla Fence Specifications

Selecting the correct technical specifications is paramount to ensuring both long-term security and optimal cost-efficiency for your gorilla fence project. The choices regarding mesh aperture, cable diameter, and material grade must be carefully calibrated to the specific occupants and structural design.

Mesh Size Analysis: 2″x2″ vs. 3″x3″

The mesh aperture, or the size of the diamond/square opening, is the most critical factor in selection. This measurement dictates the physical and psychological barrier effectiveness.

2″ x 2″ Mesh

This tight aperture is considered the premium choice for maximum security containment. For institutions housing adult male Silverbacks or young, highly manipulative gorillas, the 2″ x 2″ gorilla enclosure mesh prevents the animal from getting a solid, purchase-enabling grip on the cables. The smaller opening physically restricts the insertion of fingers or small limbs, making manipulation of the net virtually impossible. It is the ideal choice for high-tension areas and for structures where the utmost level of security is non-negotiable. While marginally higher in cost due to the increased material and labor, it provides superior peace of mind.

3″ x 3″ Mesh

The 3″ x 3″ aperture offers a highly popular, balanced, and cost-effective solution. This size provides sufficient structural integrity and physical security for larger gorilla habitat fencing structures and family groups, while maximizing light and visitor visibility. For larger enclosures where the primary goal is a strong perimeter fence rather than a close-contact barrier, the 3″ x 3″ mesh is often the perfect balance of security, visibility, and value.

Cable Diameter: Why 1/8″ (3.2mm) is Standard

The cable diameter is the main determinant of the net’s ultimate tensile strength. For heavy-duty applications like a gorilla fence, Hebmetalmesh recommends cable diameters 1/8″ (3.2mm).

This range strikes the optimal balance required: it provides industrial-grade strength and resistance to shear forces and impact, yet retains the necessary flexibility to allow for efficient installation and superior shock absorption. While thicker cables offer more ultimate strength, they become significantly heavier, less flexible, and more visually intrusive, which detracts from the naturalistic habitat goal. The 1/8″ (3.2mm) standard is proven in the field to withstand the incredible power of great apes while maintaining visual elegance.

Material: SS304 vs. Other Grades

Material composition is crucial for long-term viability. Stainless Steel Grade 304 (SS304) is the industry standard for primate enclosure netting.

SS304 is a chromium-nickel alloy that offers excellent corrosion resistance, high tensile strength, and good forming properties, making it perfect for the handweaving process. It is suitable for 99% of all inland zoo environments.

For projects located in extreme coastal or highly polluted industrial areas where salt spray or highly corrosive chemicals are a factor, Stainless Steel Grade 316 (SS316) may be briefly considered. SS316 incorporates molybdenum, providing an enhanced level of resistance to chloride corrosion (pitting). However, due to its higher cost and the fact that SS304 provides more than adequate protection in most global locations, SS304 remains the highly recommended, cost-effective, and robust choice for any professional gorilla enclosure mesh.

Color Options: Natural vs. Black Oxide

The finished aesthetic of the stainless steel zoo mesh plays a major role in achieving the desired “barrier-less” look.

Natural Stainless

The Natural finish maintains the bright, polished look of stainless steel. When properly tensioned, this finish reflects the ambient light and often blends with the sky or bright backgrounds. This finish maximizes the invisibility effect and is highly durable.

Black Oxide

The Black Oxide finish involves a specialized chemical treatment that darkens the stainless steel. This non-reflective, matte-black surface is designed to completely disappear against dark backgrounds, shadow, or foliage within the enclosure. The result is a profoundly immersive visual experience for the visitor, creating the perception of a completely open habitat, which is often the preferred choice for modern, award-winning zoo designs. This process maintains the full tensile strength of the cable without adding any coating that could chip or peel.

Hebmetalmesh Gorilla Fence Panels: Custom-Built for Your Project

At Hebmetalmesh, we understand that a gorilla fence is not a stock commodity; it is a custom-engineered structural fabric integral to a multi-million-dollar habitat. Our manufacturing process, overseen by Shijiazhuang Netting Trading Co., Ltd., is specifically optimized to produce the large, high-quality panels required for professional zoological projects.

Our Standard Large Panels: 30′ x 60′

One of our key competitive advantages is the ability to fabricate ultra-large panels, routinely reaching sizes up to 30′ x 60′ (approximately 9m x 18m). The benefit of these standard large panels is substantial. By providing massive, custom-fabricated sections, we drastically reduce the number of field seams and connections required on site.

Fewer seams mean:

- Enhanced Security: Every connection point is a potential (though minimal) weakness. Minimizing these points increases the overall, long-term integrity of the primate enclosure netting.

- Faster Installation: Large panels are quicker to hoist, tension, and secure than numerous smaller sections, leading to significant savings in labor and project timeline.

- Superior Aesthetics: A seamless, single-panel run of mesh creates a cleaner, more visually impactful barrier, further enhancing the “invisible” effect of the gorilla enclosure mesh.

The Power of Customization

Recognizing that gorilla habitat fencing projects are inherently unique, we specialize in total customization. We thrive on complex architectural demands. Every order is cut, woven, and finished to exact specifications. Whether your design calls for complex, three-dimensional shapes, tapered sections to fit curved architectural elements, or cut-outs to accommodate trees, rocks, or other habitat features, our factory can handle it.

We offer full collaboration with your engineering and design teams. Our specialists can advise on optimal mesh direction, panel segmentation, and provide custom attachment hardware, including specialized tensioning cables, edge ropes, and mounting plates, all made from corresponding high-grade stainless steel. We do not simply sell mesh; we provide a custom-engineered gorilla fence system, manufactured precisely to fit your unique vision.

Case Study: Installing a Gorilla Fence System

While the installation process varies based on structural design, the deployment of a Hebmetalmesh stainless steel zoo mesh system follows a predictable, high-precision methodology designed to ensure optimal tension, security, and aesthetics.

Step 1: Planning & Design Consultation

The process begins long before manufacturing. Our engineers work with your architects to review the enclosure drawings. This phase includes:

- Load Calculation: Determining the tension and load requirements for the structural support system (e.g., steel posts, overhead cables).

- Panel Mapping: Optimizing the size and shape of each gorilla fence panel to minimize seams, maximize material use, and simplify on-site installation logistics.

- Hardware Specification: Defining custom or standard tensioning hardware and fittings, ensuring all components are compatible and rated for the required load.

Step 2: Panel Fabrication & Quality Control

In our ISO-certified facility, the SS304 cables are cut and handwoven. The ferrules are hydraulically pressed, a process subject to rigorous quality control checks for consistency and integrity at every junction. Each custom panel of primate enclosure netting is tagged, cataloged, and inspected to ensure it perfectly matches the approved shop drawings and meets our uncompromising standards for material quality and weave consistency.

Step 3: On-Site Preparation & Anchor Point Installation

The structural framework is prepared on site. This involves installing and certifying the perimeter posts, support cables, and anchor points. These anchor points must be rated to handle the significant, sustained tension required to properly secure the mesh. Correct anchor installation is crucial to the final security of the gorilla enclosure mesh.

Step 4: Panel Hoisting & Tensioning

Panels are delivered, hoisted into position, and temporarily secured. The most critical phase is tensioning. Using specialized stainless steel perimeter cables and tensioners, the gorilla fence is systematically pulled taut along all axes. This tensioning process is what activates the net’s full load-sharing capacity, transforming the flexible mesh into a strong, resilient, and visually smooth barrier. Precision tensioning eliminates any sag or waviness, which is vital for both security and aesthetics.

Step 5: Final Inspection and Habitat Finishing

Once tensioning is complete, the entire barrier is subjected to a final security and visual inspection. The perimeter cables and attachment hardware are locked down. After final approval, the remainder of the habitat (foliage, rockwork, and animal features) can be installed, often right up against the mesh, creating the fully immersive and highly secured gorilla cage fence environment.

Hebmetalmesh: Your Trusted Partner in Wildlife Conservation

Shijiazhuang Netting Trading Co., Ltd., through our globally recognized brand Hebmetalmesh, is not merely a supplier; we are a dedicated manufacturing partner committed to supporting the critical missions of wildlife parks and zoological institutions worldwide. Our expertise lies exclusively in stainless steel woven cable applications, ensuring unparalleled focus and technical knowledge in the realm of specialized stainless steel zoo mesh.

We pride ourselves on our technical authority, dedication to quality, and ability to deliver custom, large-scale gorilla fence systems on time and within budget. When you choose Hebmetalmesh, you gain access to decades of engineering experience applied directly to the unique challenges of great ape containment.

| Hebmetalmesh Key Differentiators | Description |

|---|---|

| Factory Direct Pricing | As the direct manufacturer, we eliminate intermediary costs, ensuring optimal value for the highest quality product. |

| Over 20 Years of Experience | Deep, specialized expertise in high-tensile woven mesh applications for zoological and architectural projects globally. |

| ISO Certified Quality | Our manufacturing processes adhere to stringent international quality management standards, ensuring product reliability. |

| Project Support from Design to Delivery | Comprehensive technical consultation, load calculation, custom drawing support, and logistics management for complex projects. |

Gorilla Fence FAQ

Below are answers to common technical and logistical questions regarding the deployment of professional-grade gorilla fence systems.

A: When properly installed and tensioned, and utilizing the recommended SS304 or SS316 grade stainless steel, the material itself has an expected service life exceeding 50 years. The strength and corrosion resistance of the material mean that structural degradation is negligible over multiple decades, providing an exceptional long-term investment for your gorilla enclosure mesh.

A: Yes, absolutely. We recognize that the mounting system is as important as the mesh itself. We supply a full complement of custom-fabricated stainless steel fittings, tensioning hardware, perimeter cables, and mounting plates, all designed to integrate seamlessly with the woven mesh panels and withstand the extreme forces required for a secure primate enclosure netting system.

A: Lead times are entirely dependent on the complexity and volume of the order. For large, custom gorilla fence projects, we typically recommend a lead time of 4 to 8 weeks from the final approval of shop drawings to shipment. We work diligently with project managers to integrate our manufacturing schedule with the overall construction timeline to prevent delays.

A: Yes, this is a core component of our service. Our engineering team provides detailed technical drawings for panel fabrication, including customized sizing, shape, and aperture. We also offer consulting services for load calculations, helping your structural engineers determine the precise tensioning requirements and anchor point specifications needed to safely deploy the gorilla cage fence.

A: The vinyl ‘Gorilla Fence’ is a residential product for backyard privacy. Our handwoven stainless steel gorilla enclosure mesh is an industrial-grade solution designed specifically to contain the immense strength and intelligence of great apes in professional zoo and wildlife park settings. They are entirely different products for completely different applications.

Build a Safer, More Beautiful Gorilla Habitat

The safety of your staff, the public, and, most importantly, the welfare of the gorillas in your care hinge upon the integrity of your containment system. Settling for conventional or under-engineered fencing is a risk no professional facility should take. The design of modern gorilla habitat fencing demands a material that is technically superior, aesthetically transparent, and proven durable in the face of immense power.

Hebmetalmesh’s handwoven stainless steel cable mesh is the safe, durable, and aesthetically superior choice. By eliminating single points of failure, offering unparalleled impact absorption, and providing decades of corrosion-free performance, our gorilla fence system allows architects and planners to focus on creating enriching, naturalistic habitats without compromising security.

Take the next step toward engineering the ultimate gorilla enclosure. Contact our technical sales team for a project-specific consultation, request a detailed quote, or download our comprehensive stainless steel zoo mesh specification sheet to review technical data, load ratings, and customization options. Partner with the industry leader in high-security, high-visibility primate containment.

Various solutions for kinds of gibbon fence system

The following are the common protection schemes and specifications for different kinds of gorilla and gibbon cage protection.

In general, the size of the gorilla determines the size of the mesh aperture. The degree of the gorilla’s damage determines the wire rope diameter, and the specific specification needs to be selected according to the actual gorilla cage exhibit.

In addition, we also have the following stainless steel rope mesh product specifications suitable for application for gorilla enclosure fence protection.