Introduction: Why the Right Mesh is Your Aviary’s Most Important Decision

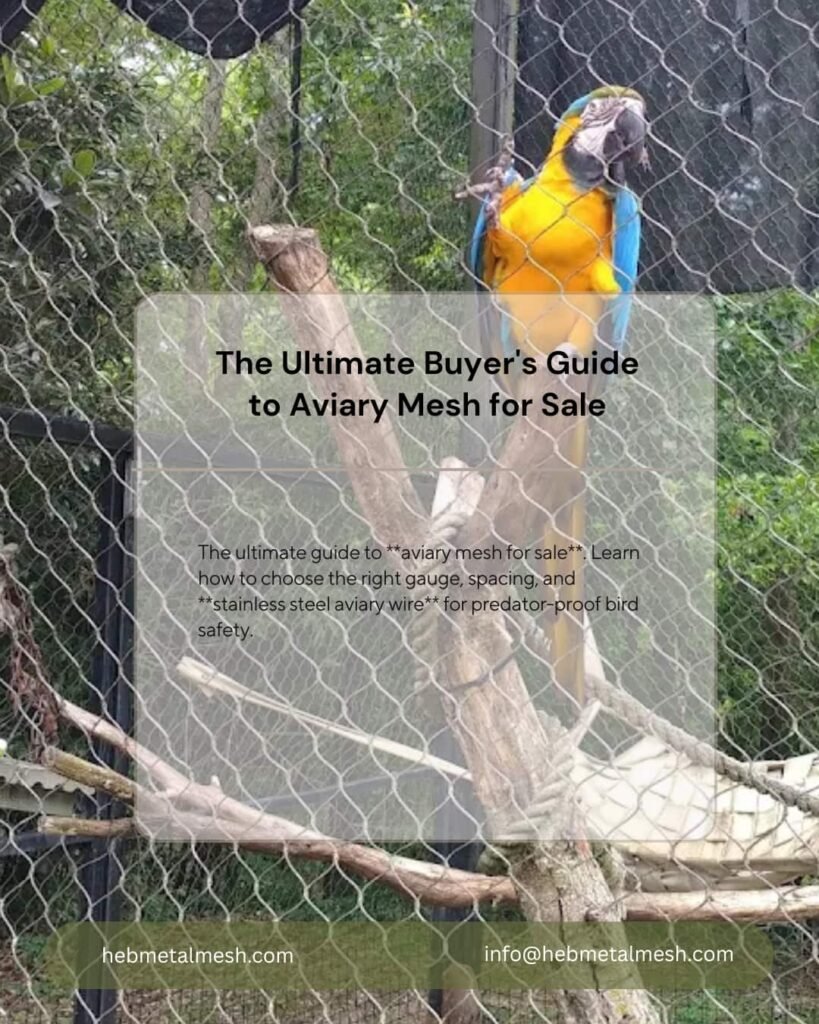

As a builder and fellow bird enthusiast, let me tell you straight: the safety and well-being of your feathered friends rests heavily on one single component—the mesh you choose for their enclosure. This isn’t a place to cut corners. Whether you’re designing a sprawling outdoor aviary or a simple indoor flight cage, selecting the wrong material can lead to devastating consequences: an easy escape for a curious parrot, a painful injury from sharp edges, or worse, a successful attack from a hungry predator. It’s simply not worth the risk.

Think of your aviary mesh as the primary line of defense, the invisible shield that protects your precious birds while giving them a safe space to fly and thrive. If you’ve been scrolling through listings wondering which option is truly the best, stop here. This guide is the definitive, no-nonsense resource you need. We’re going to walk through every material, every option, and every decision point so you can confidently find the best aviary mesh for sale and build an enclosure that will last a lifetime.

Chapter 1: Understanding Aviary Mesh – More Than Just Wire

Before we dive into materials, let’s lay the groundwork. What exactly is aviary mesh, and why do we use this term instead of, say, ‘fencing wire’ or ‘chicken wire’?

What is Aviary Mesh? (Defining the Product Category)

Aviary mesh is a specialized, woven, or welded wire fabric specifically manufactured to create safe, durable, and secure enclosures for birds and other small animals. Unlike standard fencing wire, high-quality aviary mesh is designed with two core, non-negotiable standards in mind:

- Bird Safety: It must be non-toxic, free of sharp burrs or edges that could injure delicate feet or beaks, and resistant to corrosion or flaking coatings that birds might ingest.

- Predator Exclusion: It must possess a sufficient gauge (thickness) and a small enough mesh opening to deter or prevent access from common predators like raccoons, snakes, cats, and birds of prey.

If the wire you’re looking at doesn’t meet both of these criteria, it’s not true aviary mesh, and you should steer clear of it for your project.

Common Applications

While this guide focuses primarily on bird enclosures, the principles of high-quality mesh apply to many other animal and protective applications:

- Bird Aviaries & Flight Cages: The most obvious use, ranging from enormous walk-in enclosures to small backyard structures.

- Zoological Enclosures: Used in professional settings where durability and appearance (like our black-coated options) are paramount.

- Reptile & Small Animal Habitats: Ideal for snake cages, rodent enclosures, or habitats for small primates, where secure containment and ventilation are critical.

- Garden Protection (from Pests): Strong mesh is often used to build protective cages around valuable fruit trees or vegetable patches, offering defense against squirrels, deer, or birds.

Key Terminology You Need to Know

To talk like a pro, you need to know the basic lingo. These three terms will be central to your purchasing decision:

1. Gauge: Explaining Wire Thickness

Gauge refers to the thickness of the wire itself. The key rule to remember is: the lower the gauge number, the thicker and stronger the wire.

- Lower Gauge (e.g., 14 Gauge): Very thick, strong, and highly resistant to bending or damage. This is essential for large, powerful birds like macaws or for the floor/base of an aviary where predators are a major concern.

- Higher Gauge (e.g., 19 Gauge): Thinner, more flexible, and often used for smaller bird species like finches or canaries where the birds’ strength is minimal and a lighter, less visible mesh is preferred.

A good, robust, all-around aviary mesh usually falls between 16 and 18 gauge.

2. Mesh Size / Bar Spacing: The Containment Factor

This refers to the size of the opening between the wires, often written as a measurement like 1/2″ x 1/2″ or 1″ x 1/2″. This is arguably the most critical factor for safety and security.

- Containment: The opening must be small enough that your bird cannot fit its head through it. If a bird can push its head through, it risks getting stuck, panicking, and potentially injuring its neck or suffocating.

- Predator Protection: Small mesh size prevents smaller predators (like snakes, mice, or weasels) from getting into the cage, and it minimizes the chance of a predator reaching through the wire to grab a bird.

3. Material Types: The Longevity Factor

This is the composition of the wire itself—Galvanized Steel, PVC-Coated, or Stainless Steel. This choice determines the mesh’s lifespan, its safety profile (toxicity), and its total cost of ownership. This leads us directly to our deep dive on materials.

Chapter 2: Aviary Mesh Material Showdown: Choosing the Right One for Longevity

Choosing the right material is the difference between a mesh you replace every few years and one that lasts decades. There are three main options on the market, each with distinct pros and cons.

Galvanized Steel Mesh: The Economical Choice

Galvanized steel mesh is wire that has been coated with a layer of zinc to prevent rust. It’s the cheapest option upfront and the most widely available.

- Pros: Very low initial cost, easy to find, and decent strength for the price point.

- Cons: This is where the problems start, especially with birds.

- Toxicity Risk (Zinc Poisoning): Birds, particularly parrots and cockatoos, are known chewers. When they chew on the galvanized wire, they can ingest small amounts of the zinc coating. Over time, this can lead to heavy metal poisoning, which is a serious, often fatal, illness in birds.

- Prone to Rust: Once the zinc coating is scratched, chipped, or worn thin—which happens quickly in humid environments, or where bird droppings accumulate—the underlying steel begins to rust. Rust weakens the structure and is also highly dangerous if ingested.

- Shorter Lifespan: Because of the corrosion issues, galvanized mesh has the shortest effective lifespan, often requiring replacement within 3-7 years, depending on the climate.

PVC-Coated Galvanized Mesh: A Step Up

This mesh starts with the same zinc-coated galvanized steel but then adds a layer of PVC (Polyvinyl Chloride) plastic coating over the entire wire.

- Pros: It offers more rust resistance than plain galvanized wire, especially at the weld points, and the coating is often available in colors, like green or black, which can make the mesh less visible, enhancing the aesthetic appeal of the aviary.

- Cons: The plastic coating introduces a new point of failure.

- Chewing: Again, birds chew. They can and will strip or flake off the PVC coating. This exposes the underlying galvanized wire (and the potential for zinc poisoning) or, worse, the already-rust-prone steel underneath. Ingesting PVC plastic is also not ideal.

- Coating Chip-Off: UV exposure, temperature changes, and physical stress (like climbing or impact) can cause the coating to crack and peel, allowing moisture to penetrate and rust to begin its work prematurely.

Stainless Steel Aviary Mesh: The Professional-Grade, Lifetime Solution

This is your spotlight section, and for good reason. For any serious bird owner or professional builder, stainless steel aviary wire is the unequivocal choice.

- Pros: The initial cost is higher, but the long-term value, peace of mind, and performance are unmatched.

- Unmatched Corrosion Resistance: Stainless steel is an alloy, meaning its corrosion resistance is built into the metal itself, not applied as a coating. It will not rust, even in coastal environments or high-humidity aviaries.

- Incredibly Strong: Due to its superior composition, stainless steel mesh offers greater tensile strength than galvanized steel of the same gauge.

- Non-Toxic: There are no flaking zinc or plastic coatings for your birds to ingest. This is a critical safety feature that eliminates the risk of heavy metal poisoning from the enclosure structure.

- Longevity: Stainless steel enclosures last for decades, often exceeding 25 years without deterioration. This makes the higher upfront investment significantly cheaper over the lifespan of your aviary.

Introducing Our Specific Material: 304 Stainless Steel Mesh

When we talk about the “gold standard” for outdoor and animal enclosures, we are specifically talking about 304 stainless steel mesh. This is the industry-standard alloy for applications requiring extreme durability and non-corrosion properties, such as food processing equipment, surgical instruments, and, of course, animal habitats.

The key component here is chromium. The chromium in the 304 stainless steel mesh reacts with oxygen to form a thin, invisible, self-healing layer of chromium oxide on the surface. If the mesh is scratched, that protective layer instantly repairs itself. This is why it’s completely rust-proof and safe for continuous, long-term outdoor exposure.

The Black Oxide Option: The Aesthetic Appeal

We also offer our stainless steel aviary wire with a black oxide finish. This isn’t a paint or a plastic coating; it’s a chemical treatment that darkens the surface while retaining the exact same rust and strength properties of the base 304 alloy. The benefit? A black mesh is far less reflective and virtually disappears from view when installed, offering an unobstructed, beautiful view of your birds in flight. It also reduces glare, which can be stressful for some species.

Chapter 3: Panels vs. Rolls: Which is Right for Your DIY Aviary Project?

Once you’ve settled on the superior material—hopefully, 304 stainless steel mesh—your next decision is how you want to purchase it: in pre-fabricated panels or in flexible rolls. Both formats have their place depending on the size and complexity of your project.

Aviary Mesh Panels: The Convenience of Pre-Fabrication

Aviary mesh panels are pre-cut, pre-welded, and often framed sections of mesh designed to be bolted or screwed together easily.

- Pros:

- Easy to Assemble: They are ideal for beginners and require minimal cutting. You simply attach them to your frame or to each other.

- Uniform Size: They ensure every wall of your enclosure is perfectly square and taut.

- Less Tools: You can often complete the project with just a wrench and a screwdriver.

- Cons:

- Less Flexible: They are not suitable for round, irregularly shaped, or sloped aviaries. If your structure isn’t a perfect cube or rectangle, you’ll end up with gaps and complicated joins.

- Higher Cost: Panels generally cost more per square foot because they include the cost of the pre-fabrication, extra welding, and framing material.

- Best for: Standard-shaped, smaller aviaries, modular kits, beginners, and projects where speed of assembly is key.

Aviary Mesh Rolls: The Flexibility for Custom Designs

Aviary mesh rolls are the raw, un-cut material provided in continuous lengths. This is the format preferred by professional builders and those designing large or complex structures.

- Pros:

- Cost-Effective: For large projects, buying the material in bulk aviary mesh rolls is significantly more cost-effective per square foot.

- Complete Customization: Rolls allow you to cover an entire wall or roof without seams, providing superior structural integrity and a cleaner aesthetic for truly custom aviary mesh designs.

- Less Waste: You only cut what you need.

- Cons:

- Requires More Skill: Working with heavy-gauge rolls requires more effort to unroll, cut, and stretch taut onto the frame.

- More Tools Required: You’ll need high-quality wire cutters, metal snips, and appropriate safety gear (Chapter 6 covers this).

- Best for: Large, complex, or irregularly-shaped aviaries, custom-built structures, professional builders, or anyone seeking the most material-efficient solution.

Introduce Your USP Here: Customization Without Waste

Historically, buying aviary mesh rolls meant you had to purchase standard lengths—say, 50 feet or 100 feet—even if you only needed 65 feet. This resulted in paying for 35 feet of waste or complicated, wasteful joins. We eliminate this problem.

At our factory, we provide the flexibility of a custom aviary mesh roll size with the same cost efficiency as standard rolls. You can literally order the exact length you need—down to the foot—without paying a premium for a custom order or being forced to buy more than you’ll use. This unique offering saves you money, minimizes waste, and guarantees seamless construction for even the largest enclosures.

Decision Matrix: Which Format is Right for You?

| Factor | Choose Aviary Mesh Panels if… | Choose Aviary Mesh Rolls if… |

|---|---|---|

| Project Shape | Simple, square, or rectangular. | Irregular, round, or very large. |

| Budget Priority | Time-saving and convenience. | Maximum material cost-efficiency. |

| Experience Level | Beginner or DIY novice. | Experienced builder comfortable with cutting wire. |

| Required Length | Less than 50 linear feet total. | More than 50 linear feet total or single, very long runs. |

| Finish | Looking for a pre-framed, modular look. | Looking for a seamless, professional finish. |

Chapter 4: 5 Critical Factors to Consider Before You Buy Aviary Mesh

A successful aviary project hinges on detail. Here are five non-negotiable considerations that will guide you to the perfect product specification.

1. Bird Species and Size

This is the most critical safety factor. The mesh size and gauge must be specifically tailored to the bird you are keeping. If the opening is too big, the bird can escape or get stuck. If the gauge is too thin, the bird will destroy it.

| Bird Category | Examples | Recommended Mesh Size (Bar Spacing) | Recommended Wire Gauge (Thickness) |

|---|---|---|---|

| Small Birds | Finches, Canaries, Budgies, Lovebirds | 1/2″ x 1/2″ or 3/4″ x 3/4″ | 3/64″ wire cable |

| Medium Birds | Cockatiels, Small Parrots, Conures, Quaker Parrots | 1″ x 1″ or 1.5″ x 1.5″ | 3/64″ or 1/16″ wire cable |

| Large Birds | African Greys, Macaws, Cockatoos, Amazons | 1″ x 1″ or 2″ x 2″ | 1/16″ or 5/64″ or 3/32″ cable |

A Note on Bird Cage Wire: For very small enclosures or the floor of a large aviary, a tighter 1/2” x 1/2” mesh is often used to prevent accidental injury and ensure even the smallest toes can find purchase. Never use mesh where the bird can fit its head through the opening; this is a safety hazard for any species, regardless of whether you’re using stainless steel aviary wire or another material.

2. Environmental Conditions

Where will your aviary be located? Your environment heavily dictates the longevity required from the mesh.

- Coastal Areas: If you live near the ocean, the air is saturated with salt. Salt spray is highly corrosive. Galvanized mesh will fail incredibly fast—sometimes within a year or two. Here, 304 stainless steel mesh is not just an upgrade; it’s an absolute necessity.

- High Rain/Humidity: Areas with persistent rain or high ambient humidity accelerate the corrosion process. Even if you’re inland, high moisture will quickly degrade non-stainless materials.

- Extreme Temperatures: UV exposure and large temperature swings can cause plastic coatings to become brittle and crack, leading to premature rust. Stainless steel aviary wire is completely unaffected by these elements.

3. Predator Threats

The strength of your mesh dictates how well it can resist the force of an outside attack. Consider the local wildlife.

- Raccoons and Opossums: These animals have incredible dexterity and strength. A thin-gauge wire (like 19 gauge) is easily ripped or chewed through by a determined raccoon. You need a robust 14 to 16 gauge wire to resist their attempts to breach the enclosure, especially at the base and corners.

- Snakes and Rodents: For smaller threats that can get through surprisingly small holes, you must prioritize the mesh size over the gauge. A 1/2″ x 1/2″ pattern is essential to keep out many snakes and mice, which can prey on eggs, chicks, or even stressed adult birds.

- Burrowing Threats: Always extend your mesh at least 12 inches underground around the perimeter, or lay a perimeter apron of mesh on the ground surface, to prevent predators from digging into the aviary.

4. Structural Support

The type of frame you use will influence how easily you can install your mesh.

- Wood Frames: These are easy to work with but require that the mesh be stretched taut and secured every few inches using galvanized staples or screws with large washers to prevent the mesh from pulling away.

- Metal Frames (Tubing): These are the most durable and professional option. The mesh is typically attached using hog rings, wire ties, or specialized metal clips that wrap around the frame, creating a clean, secure, and permanent bond. Aviary mesh panels often come pre-drilled to screw directly onto a metal frame.

- Tension: Regardless of the frame, the mesh must be pulled tightly to eliminate slack. Loose mesh can vibrate, causing noise, or allow a bird to chew or destroy it easily.

5. Budget vs. Long-Term Value

It’s tempting to look at the per-foot price of galvanized mesh versus stainless steel aviary wire and choose the cheaper option. But an experienced builder focuses on the total cost of ownership.

- The Cost of Replacement: Galvanized mesh, while cheap upfront, will likely need to be replaced and re-installed within 5-10 years. This involves not only the cost of new material but the significant labor of tearing down the old, rusty mesh and installing the new.

- The Cost of Risk: No price can be put on the loss of a bird due to zinc poisoning from flaking coatings or a predator attack due to structural failure.

- The Smart Investment: Investing in 304 stainless steel mesh is a one-time purchase. The higher initial cost is amortized over a lifespan of 25+ years, making it the truly cheaper, more responsible, and hassle-free choice in the long run.

Chapter 5: Why Our Stainless Steel Aviary Mesh is the Smart Investment

As a factory that specializes in high-grade animal enclosure materials, we don’t just sell aviary mesh for sale—we sell peace of mind. Here is our expert argument for why choosing our product is the right move for your project.

Unbeatable Durability: The 304 Stainless Steel Advantage

We stand by the strength and longevity of our 304 stainless steel mesh. It offers superior mechanical properties and will not degrade in performance or appearance, whether facing saltwater spray, continuous rain, or direct sunlight. When we say a “one-time purchase for a lifetime aviary,” we mean it. You build it once, and you’re done. No more annual checks for rust spots, no more tedious stripping and replacement projects.

Total Safety for Your Birds

Our wire is made from the highest quality alloy, ensuring it is completely non-toxic and free from flaking materials. Furthermore, our welding process is meticulous, resulting in smooth, strong welds that reduce the risk of sharp points or burrs, providing a smooth surface that’s gentle on delicate feet and beaks. This is not just bird cage wire; it is veterinary-grade enclosure material.

Customization Without the Cost

We’ve already mentioned it, but it bears repeating: our commitment to giving you custom aviary mesh in the form of exact-length aviary mesh rolls is a major cost saver. By ordering only what you need—whether it’s 37 feet or 212 feet—you save money and avoid the labor-intensive work of cutting away and discarding the unused remainder of a standard roll. We’ve leveraged our factory efficiency to eliminate the custom order surcharge for simple length variations.

Competitive and Transparent Pricing

We believe in making professional-grade materials accessible. We are able to offer highly competitive pricing because we are the factory—there are no middlemen. We can state right now that our pricing for quality aviary mesh starts from an incredibly competitive USD1 per sq.ft. (based on thinner gauge/higher volume).

The final price will, of course, vary depending on the gauge (thicker gauge is more expensive), the total quantity ordered, and the mesh size, but we promise complete transparency in all our quotes. We provide factory-direct pricing to ensure you are getting the absolute best value for the highest quality stainless steel aviary wire on the market.

We Are the Factory

This is a huge differentiator. As a professional factory, we control the entire manufacturing process, from sourcing the raw 304 stainless steel mesh alloy to the final welding and finishing. This allows us to guarantee consistent quality, precise dimensions, and fast lead times for both standard and custom aviary mesh orders. When you buy from us, you cut out distributors and wholesalers, ensuring you get the best product directly at the best price.

Chapter 6: A Step-by-Step Guide to Installing Your New Aviary Mesh

Even with the best materials, a poor installation can compromise the safety and integrity of your aviary. This simple guide will help you install your aviary mesh rolls or aviary mesh panels like a professional.

Tools You’ll Need

- Safety First: Heavy-duty, cut-resistant gloves and safety glasses are essential. Wire edges can be sharp!

- Cutting: High-quality metal snips or, for thick wire, a wire-cutting tool or angle grinder (with appropriate caution).

- Measuring: Tape measure, square, and marking tool.

- Attachment (Wood Frame): Heavy-duty galvanized staples and a staple gun, or self-tapping screws with large washers.

- Attachment (Metal Frame): Hog ring pliers and hog rings, or UV-resistant zip ties.

Step 1: Measuring and Cutting

If you opted for aviary mesh rolls, you need precise measurements.

- Measure Twice, Cut Once: Measure the exact section of the frame you intend to cover.

- Add 1-2 Inches: Add 1 to 2 inches (2.5 to 5 cm) extra on all sides to allow for overlap and stretching. You want to trim off the excess after you’ve secured the mesh, not run short.

- Controlled Unrolling: Unroll only the necessary length of the custom aviary mesh and cut it cleanly. Lay the mesh flat to allow the tension from the roll to relax before installation.

Step 2: Attaching to the Frame

The goal is to eliminate all slack and create a drum-tight fit.

- Initial Securement (The Top Edge): Start at the top edge of the panel or roll. Secure the mesh tightly along the entire top run every 6 to 8 inches.

- Stretching the Mesh: Move to the sides. Using a block of wood or a specialized wire stretcher, pull the mesh down and outward to eliminate sag, especially in the middle of large sections.

- The “Push-Through” Technique: For a wooden frame, slightly embed the mesh into the wood by hitting a block of wood resting on the mesh with a hammer. This ensures no gaps exist where the mesh meets the frame.

- Continuous Fastening: Continue securing the mesh every 3-4 inches along the frame using your chosen fasteners. Over-fastening is better than under-fastening.

Step 3: Ensuring a Secure and Safe Finish

- Check for Burrs: Run a gloved hand along all cut edges and frame intersections. If you feel any sharp points, use the tip of your snips to smooth them down, or use a metal file. The bird cage wire must be perfectly smooth.

- Overlap and Seams: Where one panel or roll meets another, ensure a minimum 1-inch overlap and securely fasten both layers of mesh together using hog rings or metal clips. Predators can exploit any gap you leave.

- Door and Window Gaps: The areas around doors are often the weakest points. Double-check that the door frame closes perfectly flush with the mesh and that the gap is smaller than the mesh opening size.

Frequently Asked Questions (FAQ) About Aviary Mesh for Sale

Choosing the right aviary mesh for sale can bring up a lot of questions. Here are the most common ones we hear from our customers.

A: There is no single “best” gauge, as it depends on your bird’s size and strength. A general-purpose gauge is 16-gauge (for medium parrots), while 19-gauge is often used for small birds like finches, and 14-gauge is necessary for large, powerful macaws and heavy predator threats. Always prioritize the gauge that will prevent your bird from bending or breaking the wire.

A: Absolutely. While the upfront cost is higher than galvanized or PVC-coated options, stainless steel aviary wire is a one-time investment. It eliminates the risk of toxic zinc or flaking coatings, is virtually rust-proof (especially 304 stainless steel mesh), and lasts for 25+ years, making it significantly cheaper and safer over the life of your aviary than constantly replacing inferior materials.

A: We strongly advise against using chicken wire. It is made from very thin, low-strength wire (high gauge), is typically only lightly galvanized (meaning it rusts quickly), and, crucially, has very large, hexagonal openings. The large openings provide almost no predator protection and pose a severe risk of birds getting stuck or injured. It should never be used as a primary bird cage wire material.

A: Calculate the area of each surface (length x height) and add them together. For example, an 8ft x 6ft x 10ft enclosure has six sides: (8×6) + (8×6) + (10×6) + (10×6) + (8×10) + (8×10) = 48 + 48 + 60 + 60 + 80 + 80 = 376 sq. ft. Always add 10% to account for overlap, waste, and minor mistakes.

A: Yes, we offer both pre-fabricated aviary mesh panels for quick, modular assembly and our highly popular aviary mesh rolls that can be purchased in custom aviary mesh lengths for maximum cost-efficiency and flexibility in large-scale builds.

A: Because we manufacture in-house and have optimized our cutting processes, the lead time for custom aviary mesh rolls is often the same or only slightly longer than our standard-sized rolls. Contact our sales team for an exact timeline, but generally, expect standard shipping lead times after a brief processing period.

Conclusion: Build a Safe, Beautiful, and Lasting Home for Your Birds

The choice of your mesh is the biggest decision you’ll make when building your aviary. It’s the framework of your bird’s entire world, and it needs to be safe, strong, and durable. Don’t compromise on quality now only to pay the price in replacement costs, endless maintenance, or, worst of all, a safety tragedy down the road.

Investing in the right mesh from the start means choosing the quality and peace of mind that comes with 304 stainless steel mesh. It means taking advantage of our custom aviary mesh rolls that eliminate waste and reduce your overall construction costs.

Ready to build the perfect aviary? Browse our catalog of aviary mesh for sale today and start your project with the confidence of factory-direct quality. Our experts are standing by to offer a free quote on your custom size and help you choose the perfect gauge and spacing for your unique bird species!