Introduction

Lightweight wire mesh is a versatile material that has been used for centuries to provide protection, support, and organization. From animal enclosures to garden fencing and industrial applications, wire mesh offers a wide range of possibilities.

The history of wire mesh dates back to ancient times when people used woven reeds and grasses to create barriers. Over the centuries, advancements in metalworking led to the development of more durable and versatile wire mesh products. Today, wire mesh is available in a variety of materials, including galvanized steel, aluminum, and stainless steel.

Lightweight wire mesh is particularly popular due to its many benefits. It is lightweight and easy to handle, making it a convenient option for DIY projects and larger-scale installations. Wire mesh is also durable and long-lasting, capable of withstanding harsh weather conditions and heavy use. Its versatility allows it to be used in a wide range of applications, from simple garden fencing to complex industrial structures. Finally, wire mesh is often cost-effective compared to other materials, making it an attractive choice for budget-conscious projects.

Some of the most common applications for lightweight wire mesh include:

- Animal enclosures: Cages, pens, and runs for various animals.

- Garden fencing: Keeping out pests and animals while protecting plants and flowers.

- Construction and industrial applications: Reinforcement, screening, filtration, and safety barriers.

- Decorative and artistic uses: Sculptures, installations, and interior design elements.

In the following sections, we will explore the different types of lightweight wire mesh, the materials used to make it, and the best ways to choose, install, and maintain it.

Types of Lightweight Wire Mesh

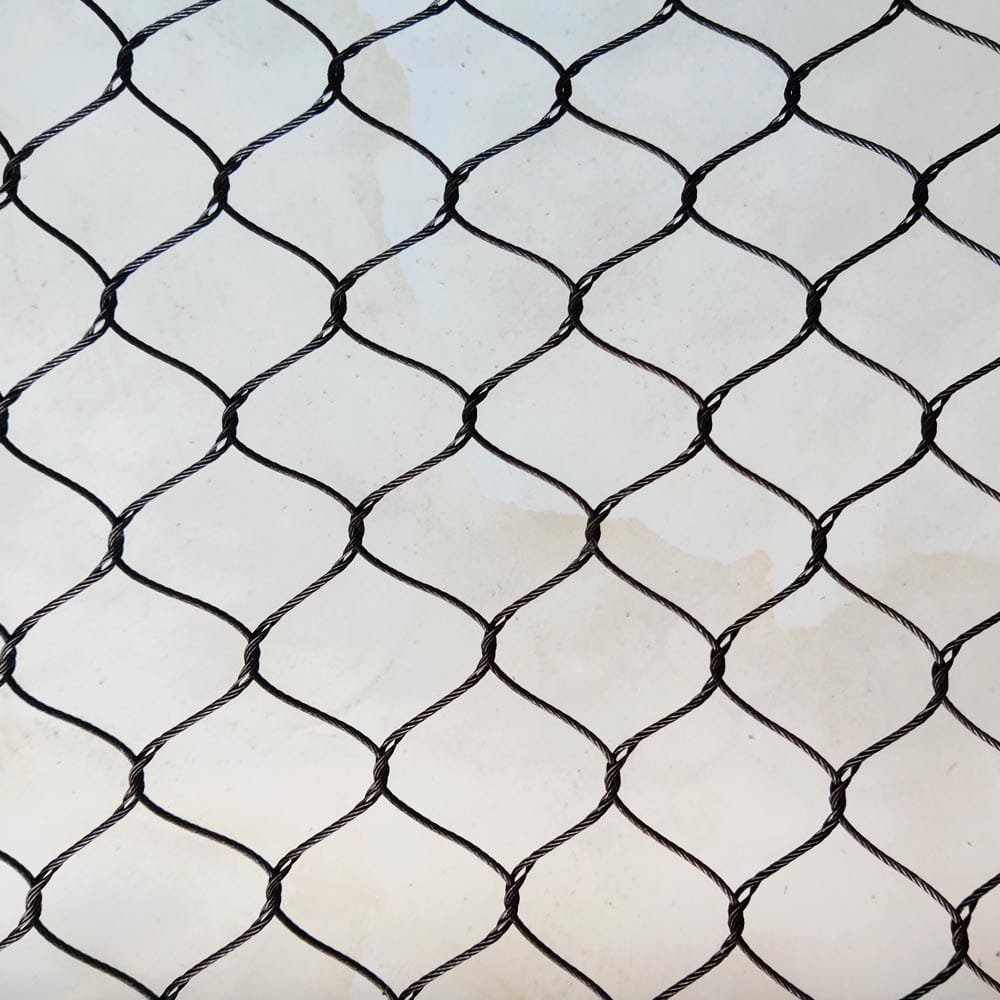

There are several different types of lightweight wire mesh, each with its own unique characteristics and applications. Let’s take a closer look at the most common options:

Welded Wire Mesh

Welded wire mesh is one of the most popular types of wire mesh. It is made by intersecting horizontal and vertical wires and then welding them together at their points of intersection. This creates a strong and durable mesh that is ideal for a wide range of applications.

Some common uses for welded wire mesh include:

- Animal enclosures: Cages, pens, and runs for various animals.

- Garden fencing: Keeping out pests and animals while protecting plants and flowers.

- Construction reinforcement: Providing structural support for concrete slabs and other structures.

- Screening and filtration: Filtering liquids and solids.

Hardware Cloth

Hardware cloth is a type of wire mesh that is made by weaving together galvanized steel wire. It is typically available in smaller mesh sizes than welded wire mesh and is often used for more delicate applications.

Some common uses for hardware cloth include:

- Pet enclosures: Cages and pens for small animals.

- Window screens: Keeping out insects and debris.

- Insect control: Protecting plants from pests.

Chicken Wire

Chicken wire is a type of wire mesh that is made from galvanized steel wire that is woven together in a hexagonal pattern. It is typically available in smaller mesh sizes than welded wire mesh or hardware cloth and is often used for poultry enclosures and other similar applications.

Some common uses for chicken wire include:

- Poultry enclosures: Cages and pens for chickens, ducks, and other poultry.

- Garden support: Providing support for climbing plants.

- Craft projects: Creating decorative items.

Expanded Metal Mesh

Expanded metal mesh is a type of wire mesh that is made by stretching and expanding a flat sheet of metal. This creates a diamond-shaped pattern that is strong and durable.

Some common uses for expanded metal mesh include:

- Architectural screening: Adding decorative elements to buildings.

- Industrial filtration: Filtering liquids and solids.

- Safety barriers: Protecting people and equipment.

Each type of lightweight wire mesh has its own unique advantages and disadvantages. The best type of wire mesh for your project will depend on your specific needs and requirements.

Materials Used in Lightweight Wire Mesh

Lightweight wire mesh is typically made from metal, although other materials can be used in certain applications. The most common materials used for wire mesh include:

Galvanized Steel

Galvanized steel is a popular choice for wire mesh due to its durability and corrosion resistance. It is made by coating steel with zinc, which protects it from rust and other forms of corrosion. This makes it ideal for outdoor use and applications where the wire mesh may be exposed to harsh weather conditions.

Aluminum

Aluminum is another popular choice for wire mesh, especially in applications where weight is a concern. It is lightweight, strong, and resistant to corrosion. However, it is not as durable as galvanized steel and may not be suitable for all applications.

Stainless Steel

Stainless steel is a high-quality material that is highly resistant to corrosion. It is often used in applications where the wire mesh will be exposed to harsh chemicals or saltwater. However, it is more expensive than galvanized steel or aluminum.

Other Materials

In addition to the materials mentioned above, other materials that can be used for wire mesh include:

- Copper: Offers good corrosion resistance and conductivity.

- Brass: A combination of copper and zinc, offering similar properties to copper.

- Bronze: A combination of copper and tin, offering strength and durability.

The best material for your wire mesh project will depend on your specific needs and requirements. Consider factors such as durability, corrosion resistance, weight, and cost when choosing a material.

Choosing the Right Lightweight Wire Mesh

When selecting lightweight wire mesh for your project, there are several factors to consider:

Application Requirements

The first thing to think about is the specific application for your wire mesh. Will it be used for animal enclosures, garden fencing, construction reinforcement, or something else? Different applications may require different types of wire mesh.

Size and Dimensions

The size and dimensions of your project will also influence your choice of wire mesh. Consider the height, width, and length of the area you need to cover. You’ll also need to determine the appropriate mesh size and gauge.

Material Compatibility

The material of the wire mesh should be compatible with its intended use. For example, if the wire mesh will be exposed to harsh chemicals, you’ll need to choose a material that is resistant to corrosion.

Budget Constraints

Your budget will also play a role in your decision. Different types of wire mesh and materials vary in cost. Consider your budget and choose a wire mesh that fits within your financial constraints.

Mesh Size and Gauge

The mesh size and gauge refer to the size and thickness of the wire used to make the mesh. A smaller mesh size will provide finer protection, while a larger mesh size will allow for better airflow and visibility. The gauge of the wire will determine the strength and durability of the mesh.

Material Selection

The material you choose will depend on factors such as durability, corrosion resistance, and cost. Consider the specific requirements of your project and choose a material that is suitable for your needs.

By carefully considering these factors, you can choose the right lightweight wire mesh for your project and ensure that it meets your specific needs.

Installation Techniques for Lightweight Wire Mesh

Once you’ve selected the right type of lightweight wire mesh for your project, you’ll need to install it properly. Here are the basic steps involved:

Preparation and Planning

- Measure the area: Determine the exact dimensions of the area where you’ll be installing the wire mesh.

- Gather tools and materials: Assemble the necessary tools and materials, including a measuring tape, wire cutters, pliers, and any necessary hardware.

- Prepare the site: Clear the area of any obstacles or debris.

Cutting and Shaping the Wire Mesh

- Measure and cut: Use the measuring tape to determine the required length of wire mesh. Cut the wire mesh to size using wire cutters.

- Shape the wire mesh: If necessary, shape the wire mesh to fit the contours of the area where it will be installed.

Attaching the Wire Mesh to a Structure

- Secure the wire mesh: Attach the wire mesh to a fence post, wall, or other structure using appropriate hardware, such as staples, zip ties, or screws.

- Tension the wire mesh: Ensure that the wire mesh is taut and does not sag.

Securing the Edges and Corners

- Reinforce the edges: Secure the edges of the wire mesh to prevent fraying or unraveling.

- Reinforce the corners: Secure the corners of the wire mesh to prevent them from becoming damaged.

Tools and Equipment

- Measuring tape

- Wire cutters

- Pliers

- Staples

- Zip ties

- Screws

- Drill (if necessary)

Safety Precautions

- Wear protective gear: Wear gloves, safety glasses, and other appropriate protective gear.

- Be careful with sharp tools: Handle wire cutters and other sharp tools with care to avoid injuries.

- Work in a safe environment: Ensure that the area where you are working is free of hazards.

By following these steps and taking appropriate safety precautions, you can successfully install lightweight wire mesh for your project.

Maintenance and Care of Lightweight Wire Mesh

Proper maintenance and care are essential to ensure the longevity and effectiveness of your lightweight wire mesh. Here are some tips:

Regular Inspection and Cleaning

- Inspect for damage: Regularly inspect the wire mesh for any signs of damage, such as holes, tears, or rust.

- Clean regularly: Remove any dirt, debris, or leaves from the wire mesh. This will help prevent rust and corrosion.

Repairing Damaged Wire Mesh

- Patch holes: Small holes can be patched using a piece of wire mesh that is similar in size and gauge. Secure the patch using staples or zip ties.

- Replace damaged sections: If the damage is extensive, you may need to replace the damaged section of wire mesh.

Protecting Wire Mesh from Corrosion and Rust

- Apply protective coatings: Consider applying a protective coating to the wire mesh, such as a rust-preventative paint or sealant.

- Store properly: If you are storing the wire mesh for extended periods, store it in a dry, sheltered location.

Preventing Sagging and Stretching

- Ensure proper installation: Ensure that the wire mesh is installed correctly and securely to prevent sagging and stretching.

- Provide adequate support: If necessary, provide additional support to the wire mesh to prevent sagging.

By following these maintenance tips, you can help to prolong the life of your lightweight wire mesh and ensure that it continues to perform its intended function.

Lightweight Wire Mesh Applications

Lightweight wire mesh has a wide range of applications, from animal enclosures to garden fencing and industrial uses. Here are some of the most common applications:

Animal Enclosures

- Cages, pens, and runs: Wire mesh is ideal for creating enclosures for various animals, including dogs, cats, rabbits, and poultry. It provides a safe and secure environment while allowing for adequate ventilation and visibility.

- Benefits for animal welfare: Wire mesh enclosures can help to improve the well-being of animals by providing them with space to exercise and socialize.

Garden Fencing

- Protecting plants and flowers: Wire mesh fencing can be used to protect gardens from pests and animals, such as deer, rabbits, and squirrels.

- Keeping out unwanted visitors: It can also be used to deter intruders and keep your property secure.

Construction and Industrial Applications

- Reinforcement and support: Wire mesh can be used to reinforce concrete slabs and other structures, providing additional strength and stability.

- Screening and filtration: It can be used to screen and filter liquids and solids in industrial processes.

- Safety barriers: Wire mesh can be used to create safety barriers around machinery and hazardous areas.

Decorative and Artistic Uses

- Sculptures and installations: Wire mesh can be used to create unique and eye-catching sculptures and installations.

- Interior design elements: It can also be used as a decorative element in interior design, such as for wall coverings or partitions.

Lightweight wire mesh is a versatile material that can be used in a wide variety of applications. Its durability, versatility, and cost-effectiveness make it a popular choice for many projects.

Conclusion

Lightweight wire mesh is a versatile and durable material that offers a wide range of benefits. It is easy to handle, long-lasting, adaptable, and cost-effective, making it a popular choice for many applications.

Some of the key benefits of lightweight wire mesh include:

- Versatility: Can be used in a wide range of applications, from animal enclosures to garden fencing and industrial uses.

- Durability: Resistant to harsh weather conditions and heavy use.

- Cost-effectiveness: Often more affordable than other materials.

- Easy to install: Can be installed with minimal tools and expertise.

If you are considering using lightweight wire mesh for your project, here are some additional resources:

- Local hardware stores: Many hardware stores carry a variety of wire mesh products.

- Online retailers: You can also find wire mesh online, often at competitive prices.

- Wire mesh manufacturers: Contacting a wire mesh manufacturer can provide you with more information about specific products and applications.

We hope this guide has been helpful in providing you with information about lightweight wire mesh. If you have any further questions, please don’t hesitate to reach out.

In conclusion, lightweight wire mesh is a valuable and versatile material that can be used for a variety of purposes. Its durability, versatility, and cost-effectiveness make it a popular choice for both DIY projects and professional applications.