Introduction

Wire Mesh Small: A Versatile Material with Endless Possibilities

Have you ever wondered about the intricate network of wires that make up that sturdy fencing or the fine mesh that filters your water? That’s wire mesh! It’s a versatile material that’s been around for centuries, quietly serving countless purposes. From the grandest construction projects to the tiniest DIY endeavors, wire mesh is everywhere.

While we often take it for granted, wire mesh plays a crucial role in our modern world. It’s the unsung hero behind countless applications, from filtering impurities to reinforcing structures. And when it comes to small wire mesh, the possibilities are even more expansive. It’s the backbone of delicate sieves, protective screens, and artistic creations.

In this comprehensive guide, we’ll delve into the world of small wire mesh. We’ll explore different types, materials, and applications, helping you understand how this remarkable material can benefit your projects. Whether you’re a DIY enthusiast, a professional in the construction industry, or simply curious about the wonders of engineering, this article is for you.

So, let’s unravel the intricacies of small wire mesh together.

Types of Small Wire Mesh

Small wire mesh comes in a variety of types, each with its unique characteristics and best-suited applications. Let’s explore some of the most common wire mesh types:

Welded Wire Mesh

Welded wire mesh is created by intersecting perpendicular wires and welding them together at the points of intersection. This process results in a sturdy and rigid mesh that’s widely used in construction, agriculture, and industrial settings. Its uniform grid pattern makes it ideal for applications requiring precise openings, such as fencing, enclosures, and reinforcement.

While strong and durable, welded wire mesh can be less flexible compared to other types. Its rigidity can also limit its use in certain applications where adaptability is crucial.

Woven Wire Mesh

Unlike welded wire mesh, woven wire mesh is created by interlacing wires together, similar to weaving fabric. This method produces a flexible and adaptable mesh with a variety of weave patterns. Woven wire mesh is commonly used in window screens, sieving, and filtration due to its ability to allow air and liquids to pass through while retaining solids.

However, woven wire mesh might not be as strong as welded wire mesh, making it less suitable for heavy-duty applications.

Perforated Metal Mesh

Perforated metal mesh is created by punching holes in a metal sheet, resulting in a pattern of open areas. This type of mesh offers a sleek and modern appearance, making it popular for decorative purposes. It’s also used in ventilation, soundproofing, and architectural applications.

While perforated metal mesh is visually appealing and offers good airflow, it might not be as strong as welded or woven wire mesh, limiting its use in structural applications.

Crimped Wire Mesh

Crimped wire mesh is produced by crimping or curving the wires in a regular pattern, creating a diamond-shaped opening. This process increases the mesh’s strength and rigidity compared to woven wire mesh. Crimped wire mesh is commonly used in construction, agriculture, and industrial applications where durability is essential.

Although crimped wire mesh is strong, its diamond-shaped openings might not be ideal for applications requiring precise filtration or screening.

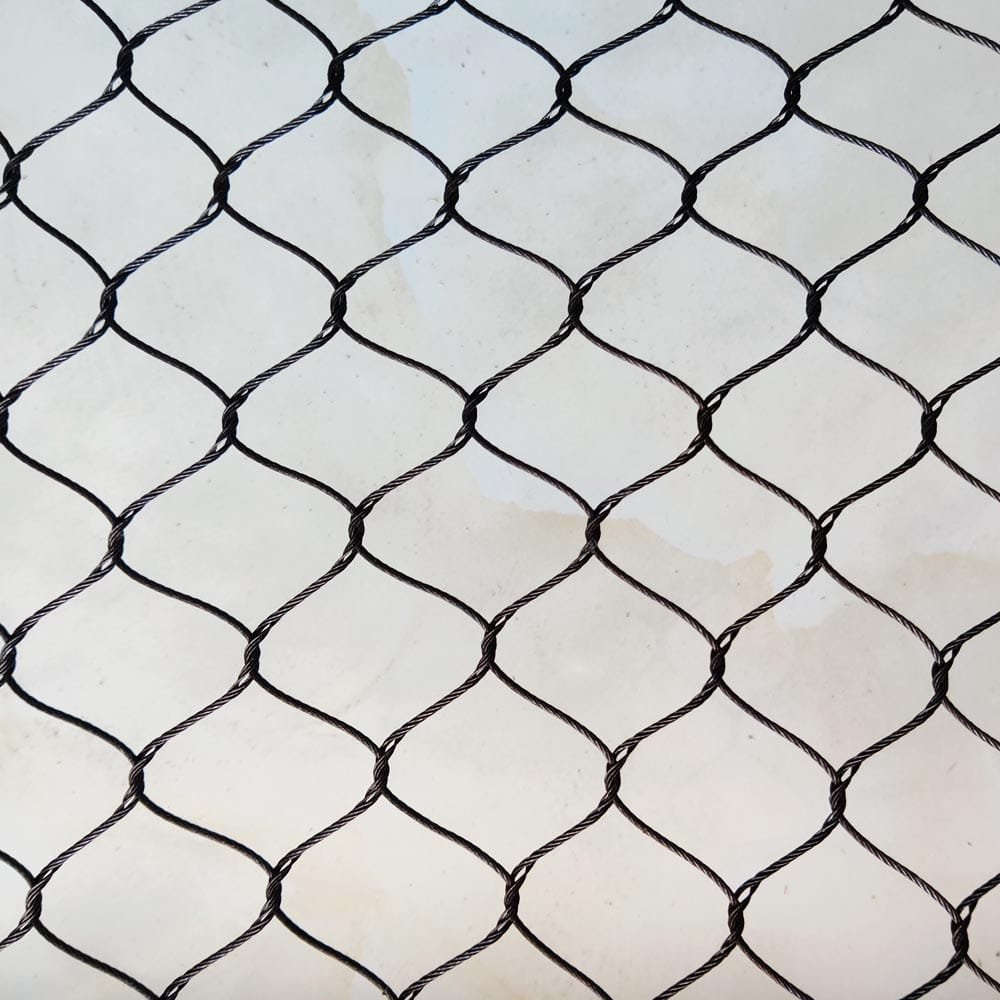

Handwoven Stainless Steel Netting

A truly exceptional choice, handwoven stainless steel netting offers a unique blend of elegance and durability. Crafted by skilled artisans, this type of mesh exhibits intricate patterns and unmatched precision. Its corrosion-resistant properties make it perfect for both indoor and outdoor use.

While handwoven stainless steel netting might be more expensive than other options, its aesthetic appeal and longevity make it a worthwhile investment for discerning customers.

Materials Used in Small Wire Mesh

The material used to create wire mesh significantly impacts its properties, such as strength, durability, and resistance to corrosion. Let’s explore some of the most common materials:

Stainless Steel

Stainless steel is a popular choice for wire mesh due to its exceptional resistance to corrosion and rust. It’s ideal for environments exposed to moisture, chemicals, or extreme weather conditions. Stainless steel wire mesh is often used in food processing, pharmaceutical industries, and marine applications.

While stainless steel offers superior durability, it tends to be more expensive than other materials.

Galvanized Steel

Galvanized steel is coated with zinc to provide corrosion protection. It’s a cost-effective option that offers good durability in moderate environments. Galvanized wire mesh is commonly used in construction, agriculture, and general industrial applications.

However, galvanized steel might not be suitable for highly corrosive environments or applications requiring high aesthetic appeal.

Aluminum

Aluminum wire mesh is lightweight, corrosion-resistant, and easy to handle. It’s often used in applications where weight is a concern, such as window screens and enclosures. Aluminum is also recyclable, making it an environmentally friendly choice.

While aluminum offers good corrosion resistance, it might not be as strong as steel, limiting its use in heavy-duty applications.

Brass

Brass wire mesh has a distinctive golden appearance and offers good corrosion resistance. It’s often used in decorative applications, marine environments, and industries requiring antimicrobial properties.

Brass wire mesh is generally more expensive than other materials and might not be as strong as steel.

Copper

Copper wire mesh possesses excellent electrical conductivity and heat transfer properties. It’s used in electrical applications, heat exchangers, and filtration systems. Copper also exhibits natural antimicrobial properties, making it suitable for food processing and medical industries.

Similar to brass, copper wire mesh can be costly and might not be the best choice for structural applications.

Other Materials

While less common, other materials like bronze and nickel can be used to create wire mesh for specific applications. These materials often offer unique properties, such as superior strength or heat resistance.

Applications of Small Wire Mesh

Small wire mesh is incredibly versatile and finds its way into countless applications across various industries. Let’s explore some of the most common uses:

Industrial Applications

Small wire mesh is indispensable in industrial settings. It plays a crucial role in filtration, sieving, and screening processes, ensuring product purity and efficiency. From separating solids from liquids to grading materials based on size, wire mesh is the go-to solution. Additionally, it’s used as reinforcement in concrete and other composite materials, enhancing their structural integrity. Conveyor belts, machinery components, and safety enclosures also benefit from the strength and durability of small wire mesh.

Construction Applications

The construction industry heavily relies on small wire mesh for various purposes. It serves as reinforcement for concrete slabs, walls, and floors, preventing cracks and enhancing structural stability. Wire mesh is also used in creating window and door screens, providing protection against insects while allowing air circulation. Security fencing, plastering, and rendering are other areas where small wire mesh proves invaluable.

Agricultural Applications

Farmers and ranchers rely on small wire mesh for a multitude of tasks. Livestock enclosures, poultry netting, and animal containment benefit from its strength and durability. Wire mesh is also used in crop protection, preventing birds and pests from damaging delicate plants. Seed sifting and grading are other agricultural applications where small wire mesh plays a vital role.

Residential Applications

Small wire mesh finds numerous applications in residential settings. Insect screens for windows and doors keep pesky bugs at bay while maintaining airflow. Pet enclosures provide safe and secure spaces for furry friends. Decorative elements like wall art and room dividers can be created using wire mesh. Garden fencing and plant supports also benefit from the versatility of this material.

Other Applications

Beyond these primary areas, small wire mesh has a wide range of other applications. It’s used in arts and crafts, hobby projects, and scientific research. Filtration systems for aquariums and pools often incorporate small wire mesh. Even the fashion industry has embraced wire mesh for unique accessories and clothing designs.

The possibilities are truly endless when it comes to the applications of small wire mesh. Its strength, durability, and versatility make it an invaluable material in countless industries and everyday life.

Choosing the Right Small Wire Mesh

Selecting the perfect small wire mesh for your project can be overwhelming with countless options available. To make an informed decision, several factors need to be considered:

Factors to Consider

- Mesh size: This refers to the number of openings per linear inch. A smaller mesh size provides finer filtration or sieving, while a larger mesh allows better airflow or visibility.

- Wire diameter: The thickness of the wire determines the mesh’s strength and durability. Thicker wires create a more robust mesh, while thinner wires offer flexibility.

- Material: Choose a material that aligns with your project’s specific requirements. Consider factors like corrosion resistance, strength, and desired aesthetics.

- Application: The intended use of the wire mesh will dictate its necessary properties. For example, a window screen requires a fine mesh with good visibility, while a security fence needs a strong and durable material.

- Budget: Different types of wire mesh vary in price, so it’s essential to consider your budget when making a selection.

Tips for Selection

- Research and planning: Thoroughly understand your project’s needs before selecting wire mesh. Consider factors like the size of particles to be filtered, the expected load, and the environmental conditions.

- Consulting experts: If you’re unsure about the best choice, seek advice from professionals who specialize in wire mesh products. They can provide valuable insights and recommendations.

- Testing different options: If possible, test various types of wire mesh to determine which one best suits your requirements. This hands-on approach can help you make an informed decision.

Maintenance and Care

Proper care ensures the longevity of your wire mesh. Regular cleaning with mild detergent and water can remove dirt and debris. For outdoor applications, consider applying a protective coating to prevent corrosion. If damage occurs, repair or replace the affected area promptly to maintain the mesh’s integrity.

By carefully considering these factors and following the tips provided, you can select the ideal small wire mesh for your project and enjoy its benefits for years to come.

Conclusion

Small wire mesh is an incredibly versatile material with a vast array of applications. From industrial powerhouses to residential comforts, its impact is undeniable. We’ve explored different types, materials, and applications, providing you with a comprehensive understanding of this remarkable product.

Remember, choosing the right small wire mesh depends on your specific needs. Consider factors like mesh size, wire diameter, material, and intended use when making your selection. Proper maintenance will ensure the longevity of your wire mesh investment.

Whether you’re a DIY enthusiast, a professional in the construction or manufacturing industry, or simply curious about the world around you, we hope this guide has expanded your knowledge of small wire mesh. Its potential is vast, and we encourage you to explore the endless possibilities it offers.

With careful planning and the right choice of wire mesh, you can unlock a world of innovation and efficiency.