Whether you’re designing a breathtaking aviary, securing a dangerous façade, or building a predator-proof animal habitat, the choice of mesh is critical. The mesh must fulfill complex structural requirements while preserving aesthetic integrity and guaranteeing occupant or spectator safety. Rigid, heavy barriers compromise sightlines; traditional fencing degrades rapidly. In contrast, the stainless steel wire rope net has emerged as the premier solution, combining unparalleled strength with minimal visual obstruction. This definitive guide from Hebmetalmesh, a leading factory in hand-woven stainless steel nets—operating under Shijiazhuang Netting Trading Co., Ltd.—will explore everything you need to know about wire rope netting, from its core advantages and material science to its vast applications and specialization options.

What is a Wire Rope Net? (Beyond Basic Definitions)

A wire rope net is far more sophisticated than simple chain-link fencing. It is a highly engineered, three-dimensional structure designed to offer flexible containment, fall protection, and subtle architectural infill.

More Than Just Fencing: The Engineering Behind the Mesh

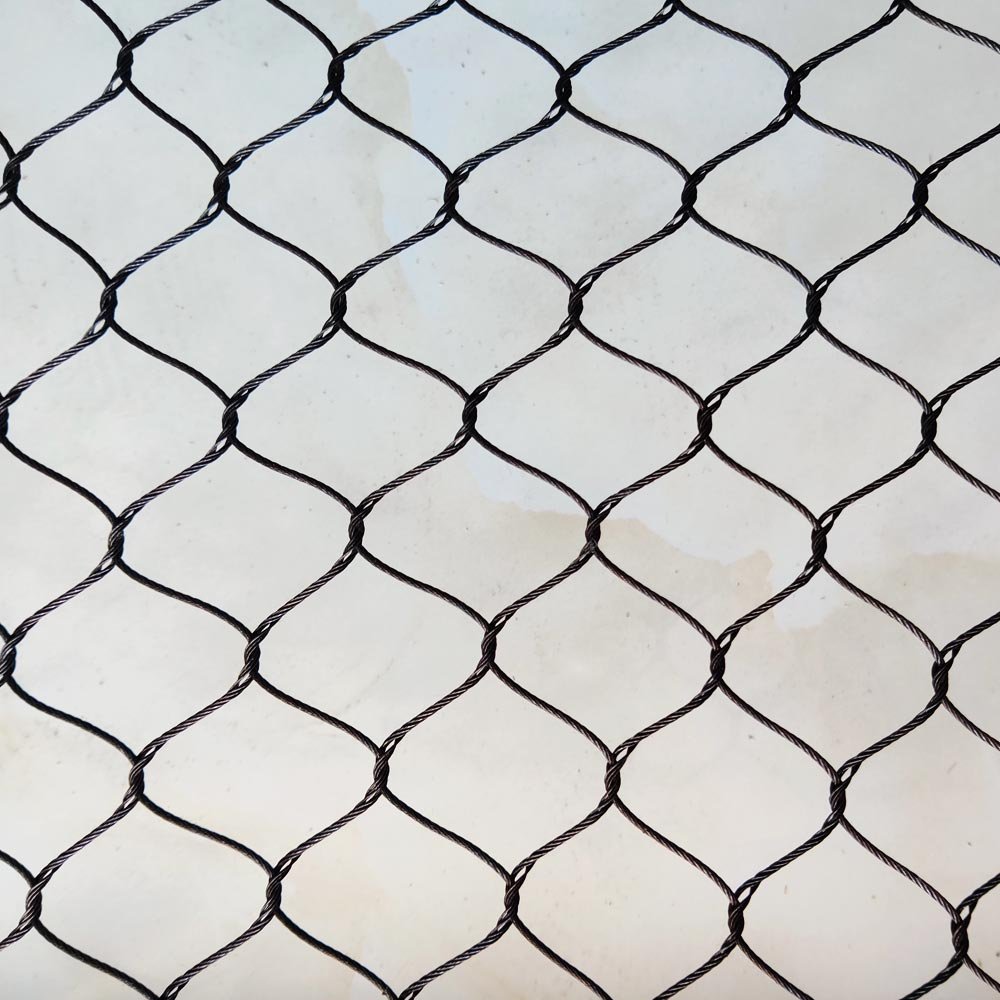

The foundation of the wire rope net lies in its unique construction. It begins not with solid wires, but with high-tensile, multi-stranded stainless steel rope mesh. Each individual wire is meticulously twisted into a compact rope, increasing both its flexibility and its ultimate tensile strength compared to a single solid strand of the same diameter.

These stainless steel ropes are then woven or interlocked to create the final net structure. Unlike many rigid mesh types, the resulting fabric is highly three-dimensional, elastic, and capable of handling complex loading patterns, particularly impact and dynamic stress.

The common pattern is a rhomboid (diamond) mesh, where ropes cross at a specific angle (typically 60 degrees, though customizable) and are secured at every intersection. This securement is vital:

- Ferrule/Clamped Net: In this common method, the crossing ropes are overlapped, and a high-strength metal ferrule (or sleeve) is pressed hydraulically around the intersection, binding the two ropes together. This creates a highly durable, structured net.

- Hand-Woven Net: This is the specialty of Hebmetalmesh and the key differentiator. Instead of clamping, the ropes are meticulously intertwined in a traditional weaving or knotting pattern. This creates a fully integral structure where the knot’s integrity is part of the rope itself, resulting in a net that is inherently stronger, more seamless, and far more adaptable to non-standard shapes and curves. This hand-woven process allows for greater consistency in knot integrity and unparalleled adaptability for custom wire rope net projects, especially large or irregularly shaped sections.

This construction results in a flexible yet incredibly strong grid pattern. The finished product is a seamless, large-scale fabric that can be easily installed, tensioned, and adapted to almost any project contour, from curved tensile structures to irregular rock faces.

Why Choose Stainless Steel Wire Rope Net? The Top 5 Advantages

When specifying materials for demanding environments—where safety, longevity, and aesthetics are equally prioritized—the benefits of stainless steel rope mesh become undeniable. This material offers a strategic advantage over alternatives like nylon, PVC-coated, or galvanized steel meshes.

Unmatched Strength and Safety

The primary advantage of stainless steel wire rope net is its exceptional strength-to-weight ratio. Thanks to the cold-drawn nature of the stainless steel, the rope exhibits remarkable tensile strength, load-bearing capacity, and resistance to impact.

For professionals designing high-consequence applications, such as large cat enclosures in zoos or industrial fall-protection systems, this strength is non-negotiable. The flexible, shock-absorbing nature of the woven mesh allows it to distribute impact load across a wider area, making it ideal for containing powerful animals or absorbing the sudden force of a falling object or person. This level of resilience ensures the containment remains predator-proof and spectator-safe.

Superior Corrosion Resistance for Longevity

Exposure to weather, pollution, and cleaning agents rapidly degrades most metallic fencing materials. Stainless steel wire rope net, however, is inherently resistant to oxidation and corrosion due to the passive chromium oxide layer that forms on its surface.

This is where material specification becomes critical:

- We introduce 304 stainless steel netting (standard grade), ideal for most general-purpose applications, including inland zoos, architectural facades, and urban environments with normal atmospheric corrosion levels.

- We also offer 316 stainless steel netting (marine grade), which contains Molybdenum—a key element that dramatically enhances resistance to pitting corrosion and crevice corrosion. This grade is essential for applications in coastal areas, maritime climates, chemical plants, or environments exposed to high salinity or chlorides. Specifying the correct grade ensures decades of maintenance-free service.

Minimal Visual Impact, Maximum Openness

Architects and zoo planners strive to create immersive, natural environments. Heavy bars and thick, high-visibility meshes detract from the visitor experience and obstruct the view of the landscape or the animals. The slim diameter of the individual ropes, combined with the open diamond pattern, gives the wire rope netting an almost transparent quality when properly tensioned.

This aesthetic appeal is one of the most compelling reasons for its architectural preference. It allows for clear, unobstructed views, integrates seamlessly with modern structural components, and maintains a sense of openness, meeting the modern design brief for “invisible barriers.”

Exceptional Flexibility and Climbability (For Animals)

For animal enclosure netting, particularly for species like primates, big cats, or certain birds, the physical interaction between the animal and the barrier is a critical welfare consideration. Rigid, hard fencing offers no enrichment and can lead to injury.

The highly flexible nature of the stainless steel wire rope net is safer and more enriching for animals. It provides a three-dimensional surface that mimics vines or branches, allowing for natural climbing behavior and physical dexterity development without the risk of abrasions or injury from rigid, sharp-edged mesh. Furthermore, this elasticity helps the netting absorb and dissipate energy from an animal’s sudden jump or charge.

Long-Term Durability and Low Maintenance

While the initial investment in a high-quality wire rope net may be higher than traditional fencing, the long-term total cost of ownership is significantly lower. These nets are designed for a lifespan exceeding 50 years. They will not rust, rot, or degrade like natural fiber nets or galvanized steel. Once installed and properly tensioned, they require minimal maintenance, eliminating the recurring costs associated with repair, replacement, and rust mitigation common with other materials.

Material Deep Dive: 304 vs. 316 Stainless Steel & The Black Oxide Option

Choosing the right material grade and finish is paramount to project success, impacting both durability and final aesthetics.

304 Stainless Steel Wire Rope Net: The Industry Standard

304 stainless steel netting is the workhorse of the industry. Composed primarily of iron, chromium (18%), and nickel (8%), it provides excellent resistance to a wide range of corrosive media and environments. It exhibits high formability and strength, making it the ideal choice for the vast majority of projects, including:

- Inland zoo mesh and aviary mesh installations.

- Standard architectural applications like stair balustrade infill and green facade support.

- General barrier and safety netting in non-industrial settings.

Its strength, reliability, and cost-effectiveness make it the benchmark material against which all other wire rope net solutions are measured.

316 Stainless Steel Wire Rope Net: For the Most Demanding Environments

When an application involves extreme environmental stress, specifying 316 stainless steel netting is essential. The key differentiator is the addition of Molybdenum, typically 2–3%.

Molybdenum significantly improves the net’s resistance to chlorides and bromides. This makes 316 stainless steel rope mesh mandatory for:

- Marine Environments: Piers, docks, offshore installations, and beachfront architecture where nets are exposed to salt spray.

- Polluted Urban/Industrial Areas: Locations with high concentrations of acid rain or chemical pollutants.

- Indoor Pool/Spa Areas: Where chlorine and humidity levels are high.

While marginally more expensive, the peace of mind offered by the enhanced corrosion protection of the 316 grade ensures the net’s structural integrity is maintained even in the harshest conditions.

Enhancing Aesthetics and Camouflage: The Black Oxide Wire Rope Net

For architectural projects or animal enclosure netting that demands ultra-low visibility, the Black Oxide finish is a crucial aesthetic and functional upgrade.

The Black Oxide process involves chemically treating the stainless steel surface to produce a thin, dark, magnetite finish. This finish provides several key benefits:

- Reduced Glare: The matte black surface absorbs light rather than reflecting it, eliminating distracting glare and reflections, particularly important in large aviaries or sun-exposed architectural screens.

- Superior Camouflage: By blending into dark backgrounds, natural shadow lines, or dense foliage, the Black Oxide net becomes virtually invisible, greatly enhancing the visitor experience and the sense of natural habitat.

- Modern Aesthetic: It provides a sleek, sophisticated, and modern look preferred by high-end architects for distinctive façade treatments and public space barriers.

This specialized finishing process underscores the commitment to delivering not just functional strength, but also bespoke aesthetic solutions.

Applications of Wire Rope Netting: Where Innovation Meets Function

The inherent flexibility and strength of wire rope net allows it to adapt to applications across numerous sectors, proving its versatility beyond traditional fencing.

Zoo Enclosures and Aviaries: A Safe Haven for Wildlife

This is perhaps the most widely recognized application of stainless steel wire rope net. The material is unmatched in its ability to safely and humanely contain animals while maximizing visibility for visitors.

- Primate and Small Mammal Enclosures: The elasticity and durability make it ideal for species that climb or test their barriers, such as monkeys, lemurs, and small carnivores.

- Bird Flight Cages: The light weight, transparency, and soft surface make it the definitive choice for large aviary mesh installations, allowing birds maximum flight space without risking injury.

- Large Predator Containment: When properly specified for rope diameter and mesh aperture, it provides powerful, predator-proof security, allowing for open-air, complex habitat design, far superior to rigid bars. The use of zoo mesh allows designers to prioritize the animal’s welfare and the visitor’s immersion simultaneously.

Architectural and Building Facades

Architects utilize the wire rope netting as a tensile fabric to achieve structural safety and distinct design elements:

- Fall Protection and Safety Barriers: Used as robust, low-visual-impact infill for balustrades, railings, parking garages, and elevated walkways, providing passive fall protection without obstructing views or light.

- Green Facades and Vertical Gardens: The nets provide an elegant, load-bearing trellis system for climbing plants, helping to insulate buildings, improve air quality, and transform dull facades into living artworks.

- Decorative and Shading Screens: Used as dynamic sunscreens or facade cladding, the mesh size can be tailored to control light and heat transmission, adding textural complexity to modern buildings.

Agricultural and Aquaculture Fencing

In farming, where barriers must be durable yet adaptable, stainless steel rope mesh is increasingly specified:

- Bird Control in Vineyards and Orchards: Lightweight aviary mesh protects high-value crops from pests without resorting to chemical solutions.

- Livestock Fencing: Offers durable containment that withstands weather cycles and animal pressure better than traditional woven wire.

- Aquaculture (Fish Farms): Utilizing 316 stainless steel netting in marine aquaculture prevents escape and protects stock from predators in high-salinity environments.

Sports and Recreation

From high-tension barriers to physical activity installations, the nets offer solutions where resilience is required:

- Safety Netting for Sports Fields: Used behind goals, on driving ranges, and around batting cages to contain balls and ensure spectator safety.

- Climbing Walls and Cargo Nets: Used in adventure parks and children’s play areas, offering a flexible, strong, and highly durable material for climbing and traversing.

The Hebmetalmesh Difference: Hand-Woven, Custom-Sized, and Built to Last

While many suppliers offer wire mesh, Hebmetalmesh (Shijiazhuang Netting Trading Co., Ltd.) specializes exclusively in the highest-grade, customized, hand-woven stainless steel wire rope net. This specialization translates into unique advantages for large, complex projects.

The Art of Hand-Woven Construction

We believe that the subtle craft of hand-weaving results in a structurally superior product compared to mass-produced, machine-clamped alternatives.

The hand-woven technique ensures that every single rope intersection is integral to the net structure, eliminating the need for external ferrules or clamps. This approach not only creates an incredibly smooth, seamless aesthetic but also ensures that the entire net surface has uniform tensile strength. When forces are applied, the load is evenly distributed across the entire net, maximizing its shock absorption and ultimate lifespan. For large custom wire rope net projects, this integrity is non-negotiable for safety and performance.

Unmatched Customization: Your Vision, Our Fabrication

One of the most frequent constraints professionals face is the limitation of standard panel sizes. Many competitors are restricted to short, manageable machine-made rolls.

Hebmetalmesh overcomes this by leveraging our hand-weaving expertise to fabricate truly colossal nets. We have the proven capability to produce single, seamless custom wire rope net rolls in extra-large dimensions, such as 30′ x 60′ (approximately 9 meters by 18 meters). This massive capability is a game-changer for large-scale aviary mesh, complex facade installations, or vast safety barriers, as it drastically reduces the number of structural joints required on-site, minimizing installation costs and improving aesthetic continuity. We are not limited to standard sizes; we fabricate to your precise specifications, down to the millimeter.

Direct Factory Pricing from Shijiazhuang Netting Trading Co., Ltd.

As the manufacturer, Shijiazhuang Netting Trading Co., Ltd. operates directly from the factory floor. This direct-purchase model offers significant benefits to business purchasers, contractors, and architects:

- Guaranteed Quality Control: Our quality assurance team oversees every step of the process, from the selection of certified 304 stainless steel netting or 316 stainless steel netting raw material to the final tensioning check of the finished net.

- Cost Savings: By eliminating middlemen, distributors, and unnecessary supply chain layers, we offer highly competitive direct factory pricing without compromising the superior quality of the hand-woven product.

- Expert Consultation: You communicate directly with the engineers and fabrication specialists, ensuring complex specifications are understood and implemented correctly the first time.

How to Specify and Order Your Custom Wire Rope Net

Specifying the correct wire rope net requires attention to detail. By clearly defining the following key parameters, you ensure the net performs perfectly for its intended application.

Key Specifications to Consider

When contacting Hebmetalmesh for a quote, be prepared to define the following five critical elements:

- Material (304 vs. 316): Determine the environmental exposure. Choose 304 stainless steel netting for standard inland use; upgrade to 316 stainless steel netting for coastal, marine, or highly corrosive environments.

- Rope Diameter: This defines the net’s ultimate strength and visual transparency. Common diameters range from 1.0mm (ultra-light aviary use) to 4.0mm (heavy-duty fall protection or large cat zoo mesh). A larger diameter means greater strength but less transparency.

- Mesh Size (Aperture): Measured as the distance between the nodes (the knots or ferrules). Mesh sizes typically range from 25mm x 25mm (1” x 1”) for small bird containment to 150mm x 150mm (6” x 6”) for architectural infill or larger animal enclosure netting. Mesh size is critical for predator containment (must be smaller than the animal’s head) and ball stopping (must be smaller than the ball).

- Overall Dimensions (L x W): Provide the exact final dimensions of the net, factoring in any necessary perimeter allowance for tensioning hardware. Remember to highlight if you require large roll sizes like 30′ x 60′ to utilize our bespoke fabrication capability.

- Finish: Specify whether you require the standard polished stainless steel finish or the aesthetic upgrade of the Black Oxide wire rope net for reduced glare and enhanced camouflage.

The Simple Ordering Process with Hebmetalmesh

Our direct factory process is streamlined for professional purchasers:

- Contact with Specs: Submit your technical drawings and the five key specifications listed above.

- Quote & Consultation: Our engineering team reviews the requirements, often providing expert advice on material grade or mesh size optimization, and delivers a free, detailed quotation.

- Production: Upon acceptance, your custom wire rope net is fabricated by our skilled hand-weaving team.

- Quality Check: Each net undergoes rigorous quality assurance to verify dimensions, knot integrity, and material grade.

- Shipping: The net is securely packaged for safe global shipping to your project site.

Frequently Asked Questions About Wire Rope Nets

We address common technical and logistical questions received from architects and contractors.

A properly specified and installed stainless steel wire rope net made from 304 or 316 marine grade material has an expected lifespan exceeding 50 years. This exceptional longevity is achieved because stainless steel is highly resistant to UV degradation, rust, and the environmental stresses that compromise most other mesh materials. The durability of the 316 stainless steel netting in particular guarantees performance over the long term, making it a sustainable choice.

Yes, absolutely. Wire rope netting is one of the most effective and aesthetically pleasing systems available for passive fall protection. When fabricated with thicker ropes (typically 2.0mm or larger) and smaller mesh sizes (50mm or 75mm), it provides the high tensile strength and shock-absorption capacity necessary to meet stringent building codes for safety barriers, balustrade infill, and overhead safety systems in construction and industrial settings.

The maintenance requirements are extremely low. The stainless steel wire rope net typically requires only occasional cleaning. For most architectural or zoo applications, simply washing the net down with plain water is sufficient. Avoid using harsh chemical cleaners, particularly those containing chlorine (unless you have specified 316 stainless steel netting, which is resistant). The material’s corrosion resistance means it will not require coating, painting, or rust removal throughout its operational life.

Lead times vary depending on the size and complexity of the order, and the current production queue. For highly specialized custom wire rope net orders, such as large 30′ x 60′ seamless panels, the fabrication time will be longer due to the hand-woven nature of the product. Generally, clients should factor in a lead time of 3 to 6 weeks from the time of order confirmation and material receipt to completion and shipping. We provide a guaranteed delivery timeline with every quote.

The difference is crucial and impacts longevity. Galvanized wire rope net has a carbon steel core coated with a layer of zinc. While the zinc offers initial corrosion protection, once this coating is scratched, chipped, or degraded (which inevitably happens under stress or impact), the carbon steel beneath begins to rust rapidly. Stainless steel wire rope net, by contrast, is resistant throughout its entire structure; the corrosion-resistant chromium oxide layer constantly self-repairs. For any permanent installation, particularly in zoo environments, animal enclosure netting, or coastal architecture, stainless steel rope mesh is vastly superior and guarantees a longer, maintenance-free life.

Conclusion

The selection of barrier material defines the ultimate success of complex architectural and zoological projects. For applications demanding the highest standards of safety, resilience, and aesthetic transparency, the custom wire rope net is the optimal choice. Its blend of high-tensile strength, inherent corrosion resistance from 304 or 316 stainless steel netting, and minimal visual impact offers an unparalleled solution.

By choosing the specialized, hand-woven fabrication methods of Hebmetalmesh (Shijiazhuang Netting Trading Co., Ltd.), you gain direct access to factory pricing, superior quality control, and the capability to realize immense, seamless structures—including industry-leading large roll sizes like 30′ x 60′.

Ready to secure your project with the finest hand-woven wire rope net? Contact the experts at Shijiazhuang Netting Trading Co., Ltd. today for a free, no-obligation quote on your custom 304 or 316 stainless steel rope mesh. Visit our website at https://hebmetalmesh.com to see more projects and specifications and start designing your invisible barrier.