Understand stainless steel wire rope safety netting for fall protection.

Choose size of stainless steel rope mesh.

Introduction to Safety Netting

Safety netting plays a pivotal role in the realm of fall protection, serving as a vital component in ensuring the safety of workers who operate at elevated heights. This protective measure has gained significant attention across various industries, especially in construction and maintenance, where the risks associated with working from heights are prevalent. The integration of safety netting systems in these environments is essential to minimize the likelihood of accidents and injuries resulting from falls.

As projects become increasingly complex and the need to work at greater heights intensifies, the importance of effective fall protection measures cannot be overstated. Safety netting provides a reliable barrier that can capture and support individuals or objects in case of unintended falls. This is particularly crucial during tasks that involve scaffolding, roofing, or elevated installation work. The presence of safety netting for fall protection not only safeguards workers but also fosters a safer working environment, enhancing overall productivity and confidence among team members.

The necessity of such safety measures extends beyond just compliance with regulations; they are imperative for safeguarding human life. Organizations are encouraged to integrate safety netting systems into their risk management strategies to cultivate a culture of safety awareness and responsibility. By doing so, they not only protect their workforce but also mitigate potential financial liabilities arising from workplace accidents. In various applications where individuals are exposed to heights, the implementation of safety netting serves as a crucial line of defense, allowing workers to operate with reduced fear and increased focus. Overall, the use of safety netting is a fundamental practice in achieving optimal safety standards in risky work environments.

Understanding Fall Protection Systems

Fall protection systems are crucial in maintaining safety in various industries, particularly those involving elevated work environments. These systems are designed to prevent falls or minimize the impact of falls when they occur. Various types of fall protection systems exist, including personal protective equipment (PPE), guardrails, and safety netting for fall protection. Each system serves a specific purpose and can be utilized in diverse applications, depending on the environment and risk factors involved.

Safety netting is a notable component of fall protection systems, particularly valuable in construction sites, industrial settings, and locations where workers are exposed to heights. This form of netting offers a reliable safety measure by effectively catching individuals who may fall, thereby preventing serious injuries or fatalities. Safety netting is typically crafted from durable materials designed to withstand significant loads and harsh conditions, ensuring optimal performance when called upon.

The installation of safety netting for fall protection provides numerous benefits. Primarily, it acts as a robust barrier that not only catches falling workers but also safeguards materials and equipment from falling debris, thus reducing overall hazards at the worksite. Additionally, the visual presence of safety netting can serve as a psychological deterrent, reminding employees of the potential dangers associated with elevated work tasks.

Another advantage is its versatility; safety netting can be used in various applications beyond construction, such as sports arenas, industrial warehouses, and even during maintenance operations in high-rise buildings. Different designs and configurations allow safety netting systems to be tailored to the specific needs and risks of any project, contributing significantly to the overall effectiveness of fall protection strategies. In conclusion, understanding the various types of fall protection systems, particularly safety netting, is vital in fostering safe work environments and reducing risks associated with falls.

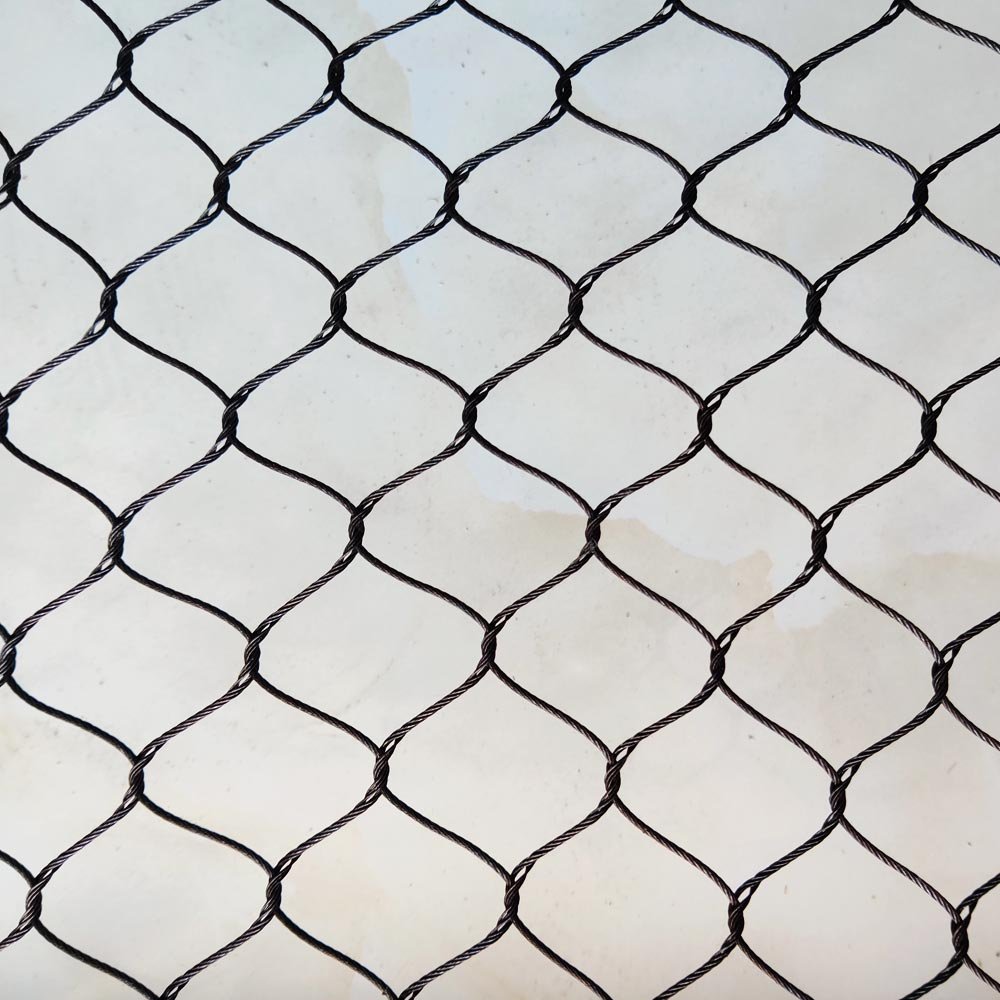

The Role of Stainless Steel Wire Rope in Safety Netting

Safety netting for fall protection is a critical component in various industries, particularly in construction, manufacturing, and maintenance tasks performed at heights. One of the most significant materials utilized in the production of safety netting systems is stainless steel wire rope. This material is favored due to its exceptional properties, which include durability, corrosion resistance, and high tensile strength.

The durability of stainless steel wire rope ensures that safety netting remains intact over prolonged periods, even under demanding conditions. Unlike traditional materials that may degrade due to exposure to environmental elements, stainless steel’s resilience allows it to withstand harsh weather, extreme temperatures, and physical stress. This characteristic is crucial for fall protection applications, as compromised netting could lead to severe accidents or injuries.

Corrosion resistance is another critical advantage of stainless steel wire rope. In environments where safety netting is exposed to moisture, chemicals, or saline conditions, traditional materials may corrode, leading to potential failures. In contrast, stainless steel exhibits remarkable resistance to corrosion, thereby enhancing the longevity of safety netting for fall protection and reducing maintenance costs associated with frequent replacements.

Moreover, the strength of stainless steel wire rope cannot be overlooked. This material is engineered to bear heavy loads, making it an ideal choice for fall protection systems that must support significant weights without compromising safety. The integration of stainless steel wire rope into safety netting systems not only ensures compliance with safety standards but also instills confidence among users regarding their protection against falls.

In conclusion, the use of stainless steel wire rope in safety netting for fall protection delivers numerous benefits that are critical for ensuring safety in height-related activities. Its durability, corrosion resistance, and strength position it as the optimal choice for creating reliable and long-lasting safety netting solutions.

Applications of Stainless Steel Wire Rope Safety Netting

Stainless steel wire rope safety netting serves as an essential component in various industries, particularly those where fall hazards are prevalent. One notable application is in construction, where workers often operate at significant heights. The installation of safety netting for fall protection not only provides a barrier against falls but also captures any falling objects, contributing to the overall safety of the construction site. For instance, a high-rise building project in New York utilized stainless steel wire rope safety netting to safeguard workers and prevent debris from posing risks to individuals below.

Another industry that benefits from stainless steel wire rope safety netting is the oil and gas sector, particularly in offshore platforms. Due to the often harsh and erratic weather conditions, ensuring employee safety is paramount. Safety netting provides a reliable means of fall protection for personnel traversing these precarious environments. In one case study, an oil platform off the coast of Texas incorporated safety netting, significantly reducing fall incidents during maintenance activities and enhancing the safety culture across their operations.

Aquaculture is yet another important field where stainless steel wire rope safety netting is utilized. Fish farms frequently require workers to manage tasks above water, leading to potential fall risks. By installing safety netting for fall protection around working areas, farms can mitigate dangers and ensure the well-being of their employees. A case involving a fishery in Norway demonstrated how the introduction of stainless steel wire rope safety netting led to a dramatic decrease in fall-related injuries, showcasing its effectiveness and reinforcing its necessity in such operational settings.

Additionally, recreational facilities and parks have adopted stainless steel wire rope safety netting in areas where climbing structures or observation platforms are present. In these situations, safety netting acts as a safeguard against falls, protecting children and adults alike. A notable example is a climbing park in California that installed safety netting, which not only enhanced participant safety but also encouraged higher visitor turnout due to the elevated safety assurance.

Across various sectors – from construction to aquaculture and recreational facilities – the implementation of stainless steel wire rope safety netting for fall protection proves to be both practical and imperative, ensuring the safety of workers and the public alike.

Production of Safety Netting Products

The production of safety netting for fall protection, particularly those crafted from stainless steel wire rope, involves a meticulous process that ensures their reliability and performance. The manufacturing phase begins with the selection of high-quality stainless steel wire, which is known for its exceptional strength, resistance to corrosion, and durability. These qualities are critical for safety netting, as they must withstand environmental factors while providing a safe environment for workers, particularly in construction and industrial settings.

After selecting the appropriate materials, the wire is processed through various techniques including weaving and knotting. These methods are essential as they determine the netting’s structural integrity and flexibility. Several configurations and mesh sizes can be engineered based on specific safety needs, thereby enhancing the customization of the safety netting. The incorporation of advanced manufacturing technologies ensures precision in mesh configuration, resulting in superior fall protection.

Quality control is a pivotal aspect of the production process. It encompasses multiple stages, including raw material inspections, in-process monitoring, and final product evaluations. Comprehensive testing for tensile strength, mesh integrity, and resistance to environmental deterioration is crucial. These tests validate that the safety netting meets or exceeds industry standards, thereby guaranteeing reliability during use. Furthermore, certifications from relevant safety organizations can enhance product credibility and help end-users trust in their efficacy.

Factors influencing the overall quality of safety netting include the manufacturing environment, equipment used, and adherence to safety regulations. Skilled personnel play an essential role in the production process, ensuring that every step is executed with precision and care. By focusing on these critical aspects, manufacturers can produce high-quality stainless steel wire rope safety netting that effectively protects individuals from falls, thereby promoting safety in various work environments.

Sales Channels for Safety Netting

The distribution and acquisition of safety netting for fall protection are facilitated through various sales channels, catering to both consumers and businesses. Understanding these channels can help stakeholders make informed purchasing decisions. Traditional brick-and-mortar stores often feature safety netting products, although these may be more limited in variety compared to online offerings. Home improvement retailers, safety equipment suppliers, and specialized industrial suppliers commonly stock an assortment of safety netting solutions, making them accessible for immediate purchase.

Online shopping provides significant advantages for obtaining safety netting for fall protection. Numerous e-commerce platforms, such as manufacturer websites and dedicated safety equipment retailers, offer extensive selections. These platforms often provide detailed specifications, customer reviews, and competitive pricing, making it easier for consumers and businesses to compare products. Additionally, many online marketplaces provide customer service support, assisting buyers in selecting the right safety netting that meets their specific needs. This convenience, coupled with the ability to read expert opinions, enhances the overall buying experience.

Another crucial sales channel involves distributors who specialize in safety equipment. These distributors typically serve businesses directly and may offer additional services such as bulk purchasing options, technical support, or safety training. Such partnerships can be advantageous for larger enterprises looking to implement comprehensive fall protection solutions. Furthermore, direct sales from manufacturers can be another viable channel, particularly for organizations that require customized safety netting solutions tailored to unique applications. Overall, whether through physical stores, online platforms, or distributor networks, the diverse channels for purchasing safety netting ensure that consumers have access to the fall protection they require.

Regulatory Standards and Compliance

In the realm of construction and industrial operations, safety is a paramount concern that necessitates adherence to various regulatory standards. Safety netting for fall protection plays a critical role in mitigating risks associated with falls, which are a leading cause of injuries in these environments. Several organizations establish guidelines to ensure the effective use of safety netting, including the Occupational Safety and Health Administration (OSHA) in the United States and the American National Standards Institute (ANSI).

OSHA regulations stipulate that safety netting must be installed and maintained in accordance with specific criteria to provide adequate fall protection. These standards encompass parameters such as the material strength of netting, the design and installation procedures, and the proper anchoring techniques crucial for effective safety measures. Compliance with such regulations is essential not only for the protection of workers but also for legal adherence, as violations can lead to severe penalties and increased liability for manufacturers and users alike.

On the international front, the ISO (International Organization for Standardization) also determines standards relevant to fall protection mechanisms, including safety netting. The ISO standards provide a framework that emphasizes the importance of performance testing and verification, ensuring that safety netting can withstand the required loads and conditions during use.

Companies utilizing safety netting for fall protection must actively stay updated with these evolving standards and actively implement training programs to ensure that all personnel comprehend the importance of these regulations. Understanding the implications of compliance not only enhances workplace safety but also builds a culture of awareness and responsibility concerning fall protection practices. Overall, the alignment with regulatory standards is a foundational aspect that must be prioritized by all stakeholders involved in safety netting implementation.

Maintenance and Inspection of Safety Netting

Regular maintenance and inspection of safety netting for fall protection is crucial to ensure its effectiveness, longevity, and compliance with safety standards. Safety netting, often composed of stainless steel wire ropes, is designed to provide a reliable barrier against falls in construction and various industrial environments. Proper upkeep not only extends the lifespan of the netting but also significantly enhances safety for personnel working at heights.

Routine inspections should be conducted at intervals, ideally at least once every three months, or more frequently depending on the environment and degree of usage. Inspectors should look for signs of wear and tear, including fraying, rust, or other forms of degradation. Each wire rope should be examined for structural integrity, checking for kinks, breaks, and any signs of corrosion. Any compromised sections of the safety netting should be addressed immediately to prevent potential accidents.

Cleaning the safety netting is equally important. Dust, debris, and environmental factors can accumulate over time and impact the performance of stainless steel wire rope netting. A gentle wash with mild detergent and water can help maintain its visibility and functional conditions. Moreover, if the netting is subjected to substances such as chemicals or salts, it should be cleaned immediately to prevent damage.

Another essential element of maintenance involves ensuring that all attachment points and anchors are secure and functioning properly. Periodic checks on the hardware used in the installation can prevent failures that could lead to severe accidents. Documentation of inspection and maintenance activities is also critical, as it contributes to accountability and assists in evaluating the safety program’s overall effectiveness.

In conclusion, a diligent approach to the maintenance and inspection of safety netting for fall protection will enhance workplace safety and foster a culture of proactive risk management. By adhering to established best practices, organizations can ensure the reliable performance of their safety systems and protect their workers from fall-related hazards.

Future Trends in Safety Netting and Fall Protection

As industries increasingly prioritize safety measures, the future of safety netting for fall protection is poised for significant transformations. Key drivers for these changes include technological advancements, materials innovation, and evolving regulatory frameworks that adapt to emerging challenges. The integration of advanced technologies, such as smart sensors in safety netting systems, will likely enhance real-time monitoring capabilities. These sensors can detect tension and potential failure points, enabling quicker responses to prevent accidents and ensuring a higher level of safety for workers.

Furthermore, innovations in materials science promise to yield more robust and lightweight safety netting options. For instance, the use of high-strength synthetic fibers and corrosion-resistant coatings can increase the durability of safety netting for fall protection, significantly extending its service life. This evolution not only improves safety outcomes but also contributes to cost-effectiveness over time. The trend toward sustainable materials is also gaining traction; manufacturers are exploring biodegradable options and recycled content, which aligns with global sustainability goals.

Another critical aspect of future developments will be the regulatory frameworks governing safety netting applications. Increased awareness of workplace hazards is driving legislators to implement stricter safety standards across various industries. As these regulations evolve, companies must adopt heightened safety protocols, incorporating advanced safety netting solutions. Compliance with these new standards will not only elevate safety but also enhance worker morale and productivity. The ongoing collaboration between government agencies, industry experts, and safety professionals will play a pivotal role in shaping regulations that prioritize fall protection.

In conclusion, the future of safety netting for fall protection is bright, with promising developments on the horizon. By embracing innovation, adhering to evolving regulations, and focusing on material advancements, industries can foster a safer working environment. The continuous commitment to enhancing safety protocols will ultimately translate into significant benefits for both workers and employers.