Introduction: The Majesty and the Mandate

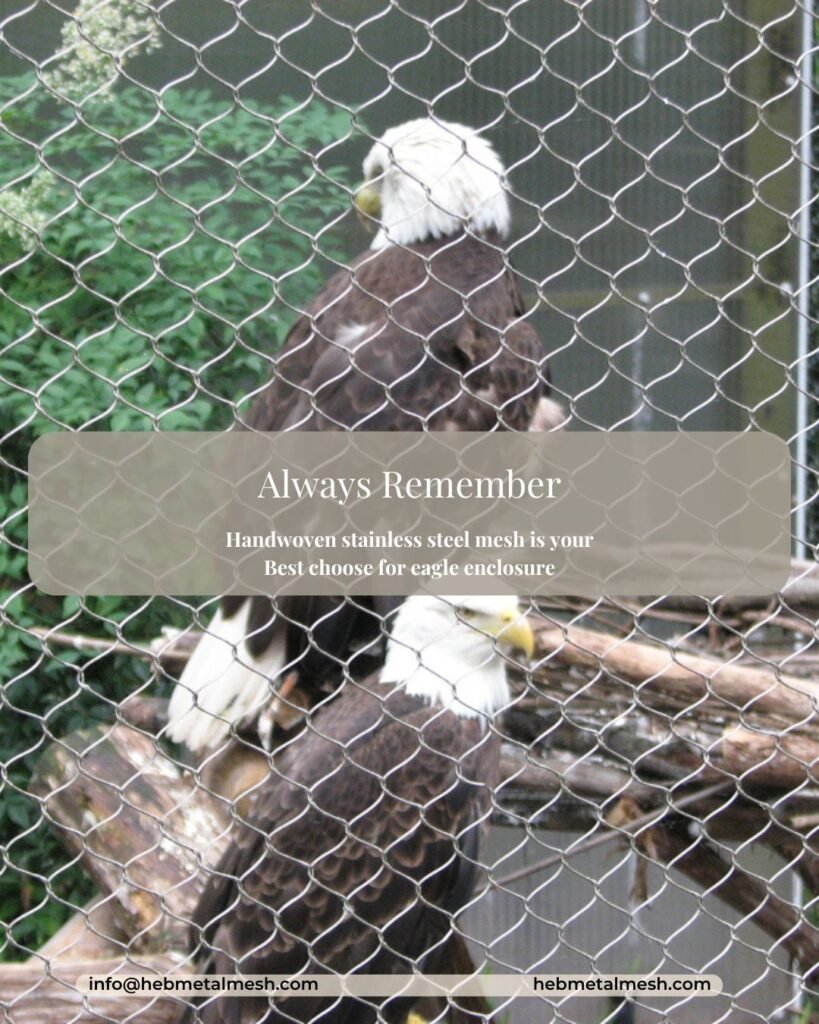

The sight of an eagle—a bald eagle soaring or a golden eagle perched—evokes an immediate sense of power, grace, and wild freedom. As one of the most recognized and potent symbols in the world, these magnificent raptors demand respect, and when they are housed in captivity, they demand the highest level of care.

Whether you operate a wildlife sanctuary dedicated to rehabilitation, a major zoological institution showcasing these apex predators, or a specialized breeding program, you bear the weighty responsibility of providing a habitat that supports their physical and mental well-being. The primary challenge in doing so is containment without compromise.

This is where the specialized eagle enclosure or “eagle fence” comes into play. It is not merely a barrier designed to keep the birds in; it is the structural boundary of their entire world. A standard fence won’t suffice for raptor containment; the sheer size, speed, and formidable talons of an eagle necessitate a robust, specialized solution.

This ultimate guide will walk you through the critical considerations for eagle fencing, from essential safety and design requirements to the most crucial element of all: the choice of material. This exploration will lead us to the superior solution that meets all professional standards: stainless steel aviary netting. This is the non-negotiable step in maintaining a professional large bird aviary.

Chapter 1: Understanding the Need for Specialized Eagle Fencing

The powerful physical attributes of eagles—their large size, their formidable talons capable of applying immense pressure, and their propensity for rapid, forceful take-offs and landings—make them vastly different from smaller, softer-billed birds. Therefore, the enclosures designed for them must be equally robust.

Why Standard Fencing Fails

Many common fencing solutions are not just inadequate for eagles—they are dangerous.

- Chicken Wire or Standard Welded Wire: These materials often use thin gauge wires and inexpensive coatings that quickly rust or degrade. Rusting wire weakens the barrier and can introduce sharp points. Zinc from galvanized coatings can also pose a toxicity risk if the birds chew or mouth the wire.

- Plastic/Nylon Netting: While lightweight, these nets are easily damaged by rodent chewing and, crucially, pose a significant risk of entanglement. An eagle’s talon, once caught, can lead to severe injury, broken bones, or worse. The rapid degradation under UV light also makes them unsuitable for long-term raptor containment.

Key Requirements of an Eagle Fence

A professional bird of prey enclosure must meet several stringent criteria to satisfy raptor safety standards:

- Containment Strength: The fence must withstand the powerful forces exerted by a large eagle during a fast landing or a desperate escape attempt. This means high-tensile strength that does not stretch or break under load.

- Predator Deterrence: The fence must be predator-proof aviary material, strong enough to resist intrusion by mammals like raccoons, foxes, and even large stray dogs that could cause panic and injury.

- Safety for the Bird: The mesh must be smooth, with no rough edges or protruding wire ends that could cause foot or talon injuries, break delicate feathers, or damage the bird’s beak.

- Durability: The material must resist weather, temperature extremes, UV exposure, and, most importantly, corrosion. Longevity is key for high-cost zoo-grade infrastructure.

- Visibility: High visibility is critical for reducing stress on the eagle and preventing ‘net strikes.’ A material that offers clear lines of sight allows the bird to feel less confined and helps them perceive the boundary more easily.

Meeting these demands requires a material specifically engineered for this niche application, which is why stainless steel aviary netting has become the preferred choice worldwide.

Chapter 2: The Critical Choice: Comparing Aviary Netting Materials

The long-term safety and success of your large bird aviary hinge on the netting material you select. Here is a detailed comparison of common options, highlighting the clear winner.

Material Showdown

| Material | Pros | Cons | Eagle Suitability |

|---|---|---|---|

| Galvanized Steel Wire | Lower initial cost, relatively strong. | Prone to rust when coating is breached; risk of zinc toxicity if ingested; shorter lifespan. | Poor: Rust and toxicity risks make it unsuitable for high-value raptors. |

| Powder-Coated Wire | Available in different colors, better aesthetic appeal initially. | Coating chips easily, exposing the base metal to rust; coating can be scratched by talons; costly to repair. | Fair: Better than galvanized, but poor long-term durability and safety concerns once chipped. |

| Nylon/Polyethylene Netting | Very lightweight, cheap, flexible. | Prone to tearing and entanglement injuries; susceptible to UV degradation; easily chewed through by rodents or bent by wind/snow loads. | Poor: High safety risk due to entanglement and low containment strength. |

| Stainless Steel Aviary Netting | Unmatched durability, superior strength, bird-safe, non-toxic, aesthetically pleasing. | Higher initial investment. | Excellent: The industry gold standard for long-term safety and structural integrity. |

Deep Dive: Why Stainless Steel is Unbeatable for Eagle Fences

When discussing galvanized vs stainless steel aviary options for an eagle, stainless steel consistently comes out on top due to its unique metallurgical properties.

Unmatched Corrosion Resistance

Eagles are housed across diverse climates, from humid coastal regions to dry mountain air. Unlike other metals that rely on a protective coating, stainless steel is inherently corrosion-resistant bird netting due to the presence of chromium. This element creates a passive, self-healing oxide layer on the surface. This means that even if an eagle’s talon or beak scratches the wire, it won’t rust, ensuring the structural integrity and appearance remain intact for decades.

Exceptional Strength-to-Weight Ratio

A large eagle fence requires netting with immense strength to handle the dynamics of a raptor habitat, but it cannot be so heavy that it necessitates an overly massive and expensive supporting structure. Stainless steel aviary mesh provides high-tensile strength from relatively thin wires, offering a lighter, more elegant solution that maintains maximum security.

Non-Toxic and Bird-Safe

Stainless steel is chemically inert and non-toxic, eliminating the risk of heavy metal poisoning associated with galvanized coatings. Furthermore, the specialized construction used by manufacturers like Hebmetalmesh—typically a smooth, woven or precision-welded finish—prevents injuries. The flexibility and smooth surface ensure that if an eagle bumps the mesh, it is not injured or damaged.

Long-Term Value

While the initial investment for a long-lasting eagle enclosure made from stainless steel may be higher than cheaper alternatives, its lifespan of several decades drastically reduces future replacement, maintenance, and repair costs. For permanent, professional installations, this superior longevity translates into true long-term value. This material guarantees safety and security for the eagles and peace of mind for their caretakers.

Chapter 3: Introducing the Hebmetalmesh Solution: Engineered for Excellence

When it comes to sourcing premium stainless steel aviary netting, manufacturers like Hebmetalmesh have engineered products that meet the rigorous demands of eagle care and professional zoo standards. Choosing a specialist supplier is key to ensuring compliance and ultimate bird safety.

Product Spotlight: Hebmetalmesh Stainless Steel Netting

Hebmetalmesh focuses solely on high-quality mesh and netting solutions, translating into products optimized for demanding wildlife enclosures.

- High-Quality Stainless Steel: Hebmetalmesh uses specific, professional-grade alloys. We primarily recommend 304 grade stainless steel for most climates, which offers excellent corrosion resistance and strength. For highly corrosive environments, such as facilities directly on the coast or in high-humidity areas, 316 grade stainless steel—known for its enhanced resistance to salts and chlorides—is the ideal choice.

- Precision Welding or Woven Construction: For the safety of eagles, the finished product must be flawlessly smooth. Our nets feature precision welding or expertly woven constructions that eliminate sharp edges, ensuring that the bird’s feathers and talons remain undamaged, even during powerful interactions with the mesh.

- Various Mesh Sizes: The size of the diamond or square aperture is critical. For large eagles, a balance is needed between visibility and security. While a standard mesh may work for smaller raptors, larger birds require a size like 2″ x 2″ or 2″ x 1″ to prevent any risk of talon entanglement while maintaining its structural integrity. Hebmetalmesh stainless steel netting is available in various mesh sizes and wire gauges to suit both eaglets and mature birds, as well as providing effective rodent exclusion.

- Customizable Panel Sizes: Every aviary project is unique, from rehabilitation flight cages to expansive walk-through exhibits. We offer custom aviary mesh panels tailored to your precise dimensions, reducing waste and simplifying the installation process. This ensures that every inch of your professional zoo-grade netting solution is perfectly fitted.

By choosing Hebmetalmesh, you are not just buying wire; you are investing in a high-tensile bird netting solution engineered specifically for the safety and containment of your most precious raptors.

Chapter 4: Designing and Planning Your Eagle Enclosure

The highest quality mesh is only as effective as the structure supporting it. Building an eagle habitat requires a holistic approach that goes beyond the mesh itself. A well-executed aviary design plan works in perfect tandem with the stainless steel netting to create a secure, stable, and visually appealing home.

Structural Framework Considerations

The framework is the skeleton of your eagle flight enclosure. Given the lifespan of stainless steel aviary netting (often 20+ years), the support structure must be equally durable.

- Material Choice: The most common choices are heavy-gauge galvanized steel tubing (with high-quality post-weld coating) or robust, pressure-treated timber. The framework must be rated to handle not only the weight of the mesh and the birds but also significant environmental loads from wind and snow.

- Anchoring: Posts must be securely anchored in concrete deep below the frost line to prevent shifting, which could compromise the mesh tension and integrity.

- Entry Points: Access doors and feeding ports must be designed with double-door vestibules or secured entry points to ensure that if a bird escapes the main habitat, it remains contained within a secondary safety zone.

Enclosure Shape, Size, and Enrichment

The size and shape of the enclosure are crucial for the eagle’s physical health, allowing for adequate flight and exercise.

- Flight Space: The habitat should be long enough to allow an eagle to fully extend its wings and take several wingbeats in flight. For rehabilitation, size standards are set by governing bodies, but generally, the bigger and taller, the better.

- Perches and Heights: Include a variety of naturalistic perches at different heights and diameters (wood, rope, synthetic materials) to mimic a natural environment. High perches should be installed to allow the eagle to survey its territory, which is vital for its mental well-being.

- Environmental Enrichment: The design should incorporate elements like pools, dusting areas, and areas of privacy or shelter to encourage natural behaviors.

Integration with Mesh: The Importance of Tension

During zoo exhibit construction, proper mesh integration is paramount. The goal is to install the stainless steel mesh installation tautly across the entire frame. A taut mesh is safer because it prevents birds from getting a toehold and minimizes “bounce” during landings. The flexibility of custom panels from Hebmetalmesh allows for efficient, low-waste installation on complex, non-rectangular aviary designs.

Chapter 5: Installation Best Practices for Your Eagle Fence

While the exceptional durability of stainless steel ensures a long life, correct installation is what guarantees immediate and future security. Large-scale eagle fence installation is best handled by experienced contractors, but here is a high-level guide to the key steps.

Step-by-Step Guidance

- Site Preparation and Grounding: The perimeter must be fully secured. A common method to create a predator-proof aviary is to bury the bottom edge of the mesh into the ground or attach it to a concrete footer or skirt. This prevents animals from digging in and eagles from potentially digging out.

- Assembling the Support Structure: Ensure the frame is plumb, square, and structurally sound before attaching the mesh. All cross-beams and bracing that the mesh will attach to should be finalized.

- Unrolling and Handling the Stainless Steel Mesh: Stainless steel aviary mesh, particularly larger rolls, can be heavy and requires careful handling. The goal is to prevent kinking or permanent creases, which can weaken the tensile strength. Rolls should be unwound slowly and secured immediately.

- Attaching the Mesh Securely: The mesh is typically attached to the frame using a variety of fasteners: stainless steel hog rings, heavy-duty cable ties, or lacing wire. The attachments must be placed at regular, close intervals (e.g., every 6 inches) to prevent any gaps or sagging that could invite escape or intrusion.

- Tensioning and Finishing: Tensioning stainless steel mesh is perhaps the most critical step. Specialty tools are often used to pull the netting uniformly tight, eliminating slack. A taut installation ensures a clean, professional look and drastically improves safety. Once fully tensioned, the final cuts and trims are made to ensure there are no loose ends or sharp wires protruding.

Safety First

Due to the size, height, and materials involved, we strongly recommend working with construction professionals who are familiar with how to install aviary netting and specialized tensioning requirements. Proper aviary construction tips often revolve around safety, ensuring that all joins and edges are smooth and sealed.

Chapter 6: Maintenance and Long-Term Care of Your Stainless Steel Eagle Fence

One of the greatest benefits of investing in a premium stainless steel eagle fence is the drastically reduced maintenance burden over its lifetime.

The Low-Maintenance Advantage

Because Hebmetalmesh’s stainless steel netting resists rust and UV degradation, it requires none of the regular painting, repair of chipped coatings, or patching that other materials demand. Once installed correctly, the mesh itself should require minimal attention. This translates to reduced labor costs and fewer disturbances to the eagles inside the enclosure.

Routine Checks

While the material is low-maintenance, the structure requires regular checks to ensure ongoing safety.

- Structural Integrity: Periodically inspect all load-bearing posts and beams for any signs of settling, rot (if timber is used), or damage from weather events.

- Tension: Check the tension of the mesh, particularly after extreme weather. Re-tensioning might be necessary occasionally to ensure the mesh remains taut and does not create dangerous slack areas.

- Perimeter Grounding: Inspect the perimeter for any signs of digging (in or out) and verify that the bottom edge of the mesh is still securely anchored to the ground or footer.

Cleaning

Cleaning aviary mesh is straightforward. Stainless steel is easy to clean, often requiring only a rinse with water and perhaps a mild detergent to remove any accumulated debris or natural residue. This cleaning process also provides an excellent opportunity to perform a detailed visual inspection of the entire surface for any rare damage.

Choosing durable low-maintenance fencing like stainless steel means you can focus your resources on the health and care of the eagles, rather than constant enclosure repairs.

Conclusion: Investing in Peace of Mind

Housing an eagle is a profound commitment, one that requires uncompromising standards in safety and containment. We have established that standard materials fail this test, presenting unacceptable risks of injury, corrosion, and breach.

The solution is clear: stainless steel aviary netting stands as the ultimate material for any professional eagle fence. Its combination of inert, non-toxic composition, unmatched corrosion resistance, superior strength, and longevity makes it the only truly long-term investment.

By choosing a quality product from a trusted manufacturer like Hebmetalmesh, you are making an investment in the safety, well-being, and longevity of your eagle habitat. You are buying peace of mind, knowing that your enclosure meets the highest possible standards for these magnificent birds.

Call to Action (CTA)

Ready to build the safest home for your eagles? Explore Hebmetalmesh’s range of professional-grade stainless steel aviary netting solutions and request a quote for your custom project today.

Frequently Asked Questions (FAQ)

A: For large eagles, a mesh size of 2″ x 2″ is often recommended. This size effectively contains the bird and minimizes the risk of talon entanglement while ensuring the required strength. Hebmetalmesh offers various sizes to perfectly match your specific bird and environmental requirements.

A: Cost varies widely based on the size of the enclosure, the complexity of the design, and the gauge of the wire chosen. While the initial investment for stainless steel is higher than for cheaper materials like galvanized wire, the decades-long lifespan and elimination of replacement costs mean it offers superior long-term value.

A: High-tensile, professionally manufactured stainless steel netting from brands like Hebmetalmesh is specifically designed to contain the powerful force of large birds of prey. When correctly installed and tensioned on a proper frame, this material is virtually indestructible by eagles.

A: It is available from specialized manufacturers and suppliers. For custom, high-quality, zoo-grade solutions, you can contact Hebmetalmesh directly for specifications, custom panel sizing, and pricing details.