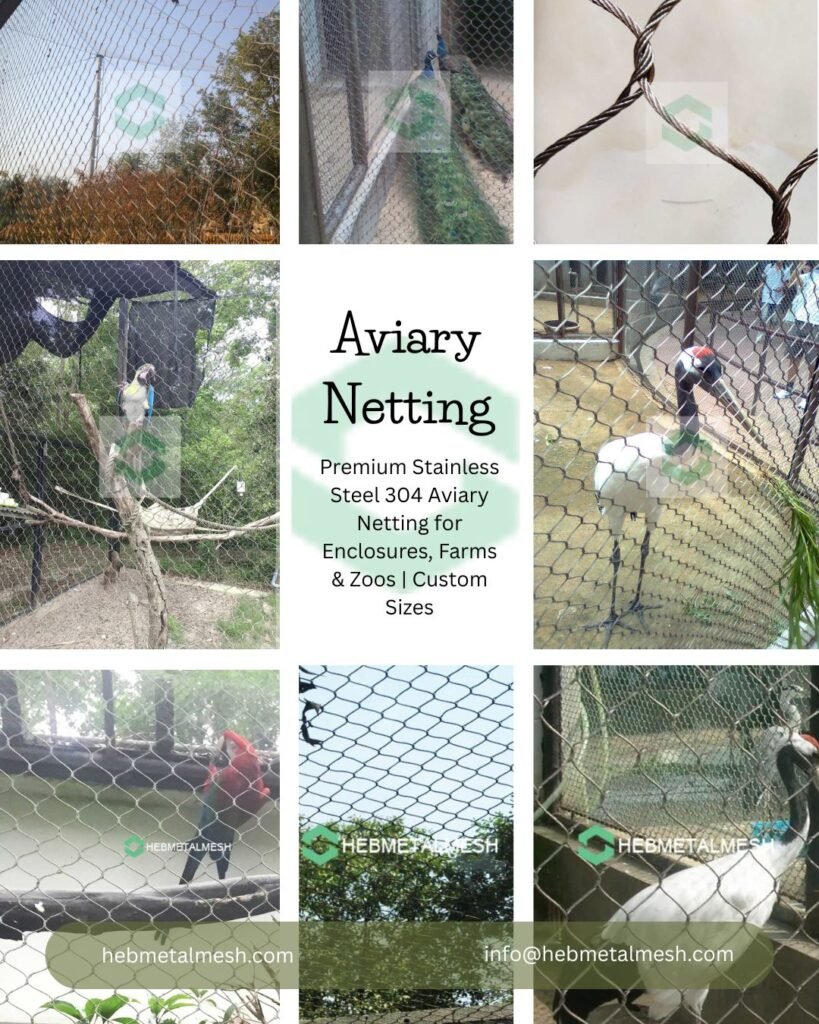

For zoo curators, landscape architects, commercial farm managers, and private aviary enthusiasts, the structural integrity of a bird enclosure is paramount. The term “flight netting” encompasses a wide range of materials, but the industry has seen a massive shift toward stainless steel as the permanent solution for modern animal husbandry.

At Hebmetalmesh, we have witnessed the evolution of these materials firsthand. From our factory floor to the world’s most expansive wild parks, we’ve seen how the right mesh can transform an environment. This guide serves as a technical manual and a buyer’s roadmap for anyone looking to invest in the future of their avian facilities.

1. The Evolution of Flight Netting: From Nylon to Stainless Steel

Historically, flight netting was a commodity of convenience. In the early days of zoo design and poultry farming, nylon and polyethylene (PE) nets were the standard. They were cheap, lightweight, and easy to hang. However, as the industry moved toward higher standards of animal welfare and long-term economic sustainability, the flaws of synthetic netting became impossible to ignore.

The Problem with Synthetic Netting

Nylon and plastic nets suffer from UV degradation. Even with UV stabilizers, the constant exposure to sunlight causes the polymers to become brittle. In a matter of years, the netting loses its tensile strength, leading to “ghost breaks” where the netting snaps under the weight of a single bird or a light dusting of snow. Furthermore, synthetic nets are vulnerable to “chew-through” by rodents and predators, creating escape routes that can devastate a bird collection or a commercial flock.

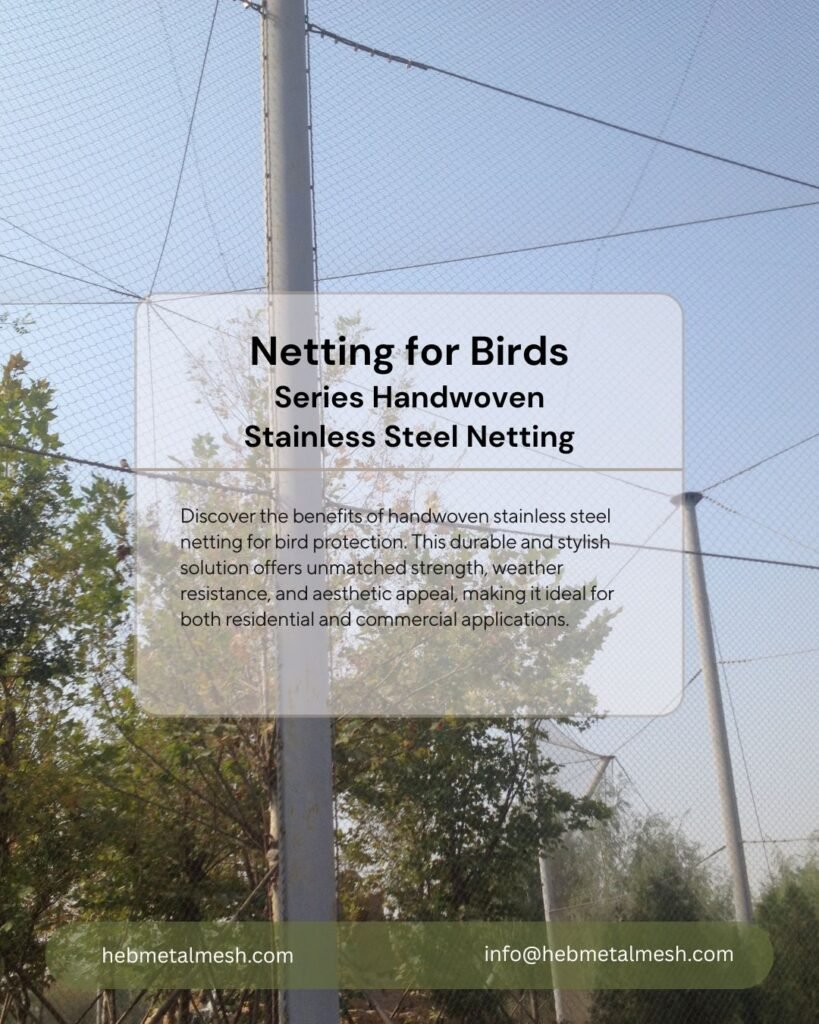

The Rise of Handwoven Stainless Steel

The introduction of handwoven stainless steel wire mesh changed the landscape. Unlike rigid welded wire, which feels like a cage, handwoven mesh feels like a fabric. It provides the strength of steel with a flexible geometry that can follow the complex curves of modern “bio-designed” aviaries. At Hebmetalmesh, we specialize in this specific medium, providing a product that lasts 30 years or more with zero maintenance.

2. What are the Best Types of Flight Netting for Commercial Poultry Farms?

In the commercial sector, flight netting is often referred to as “predator netting” or “biosecurity mesh.” The requirements here are strictly functional: durability, exclusion, and ROI.

Biosecurity and Disease Prevention

With the global rise of avian influenza, commercial poultry farms are under immense pressure to prevent contact between wild birds and domestic flocks. Small wild birds, such as sparrows and starlings, can easily slip through standard 2-inch plastic netting.

- Recommendation: A 1-inch (25mm) or 1.25-inch (32mm) stainless steel mesh aperture is ideal. It is tight enough to exclude most wild carriers while remaining open enough to allow for airflow and natural light.

Predator Protection

Foxes, raccoons, and hawks are persistent. A determined predator can bite through heavy-duty plastic netting in minutes. Stainless steel flight netting acts as a physical barrier that is impossible for animals to chew or claw through.

- Hebmetalmesh Tip: For ground-level poultry runs, we recommend burying at least 12 inches of the netting into the soil or attaching it to a concrete footer to prevent burrowing predators from gaining entry.

Snow Load and Wind Resistance

In northern climates, snow accumulation on top of an enclosure can lead to a catastrophic collapse. Because stainless steel has a much higher strength-to-weight ratio than plastic, it can support significantly higher loads. Our handwoven structure allows wind to pass through with minimal resistance (high transparency), reducing the “sail effect” that can knock down supporting poles during a storm.

3. What Materials are Used in High-Quality Flight Netting Products?

Understanding the materials is the difference between a project that lasts five years and one that lasts fifty. At the Hebmetalmesh factory, we focus on two primary grades of stainless steel and two distinct finishes.

Grade 304 vs. Grade 316

- AISI 304 Stainless Steel: This is the industry standard. It contains 18% chromium and 8% nickel, providing excellent corrosion resistance for most inland environments. It is cost-effective and highly durable.

- AISI 316 Stainless Steel: Often called “Marine Grade,” 316 contains an addition of molybdenum. This makes it exceptionally resistant to chlorides (salt). If your project is within 5 miles of the ocean, Grade 316 is a non-negotiable requirement to prevent “tea staining” or surface rust.

The Handwoven Craftsmanship

Our netting is not made by a machine; it is hand-interlaced. This process creates a rhombus (diamond) mesh pattern. The beauty of this design lies in its flexibility. It can be stretched like an accordion to fit around trees, rocks, and uneven terrain.

- The “Knot” Factor: The inter-woven knots are smoothed during the manufacturing process to ensure there are no sharp edges that could snag feathers or cut a bird’s feet.

Black Oxide vs. Natural Finish

- Natural Silver Finish: This finish has a high-tech, industrial look. It is often used in modern architectural projects or for farm fencing where visibility is not a primary concern.

- Black Oxide Finish: This is a chemical treatment that turns the silver steel into a deep, matte black. In the world of zoo design, this is the preferred choice. Black mesh does not reflect sunlight, meaning the human eye focuses past the mesh and onto the birds. It creates an “invisible” barrier that improves the visitor experience.

4. Where Can I Buy Durable Flight Netting for Bird Control?

Finding a reliable supplier is often the hardest part of a construction project. Many distributors sell “general-purpose” netting that isn’t rated for the long-term stress of a flight enclosure.

The Factory-Direct Advantage

At Hebmetalmesh, we operate as both the manufacturer and the seller. This provides three distinct advantages to our customers:

- Cost Efficiency: By purchasing directly from our , you avoid the 30-50% markup typically added by local distributors.

- Customization: We don’t just sell standard rolls. We manufacture custom roll sizes tailored to your specific pole-to-pole measurements. This saves you hours of labor on-site and reduces material waste to nearly zero.

- Large Panel Capability: One of our standout features is the ability to produce massive panels, up to 30′ x 60′ (9m x 18m). Large panels mean fewer seams, which translates to a stronger and more beautiful enclosure.

5. Technical Specifications: The Science of Mesh Selection

Selecting the right “specification” is a balance of wire diameter and aperture (hole) size. Here is a breakdown of how we classify flight netting for different applications.

Wire Diameter

The thickness of the wire determines the strength.

- 1.2mm (3/64″): Ideal for small aviaries, songbirds, and light-duty farm use.

- 1.5mm (1/16″): The “sweet spot” for most zoo aviaries. It is strong enough to resist larger birds but thin enough to remain nearly invisible.

- 2.0mm – 2.4mm (5/64″ – 3/32″): Used for large raptors (eagles, vultures) or for the lower “kick zone” of an enclosure where human contact or large animals might push against the mesh.

Mesh Aperture (Opening Size)

- 20mm x 20mm (0.8″ x 0.8″): Excludes even the smallest finches and local pests.

- 25mm x 25mm (1″ x 1″): Standard for parakeets and small parrots.

- 38mm x 38mm (1.5″ x 1.5″): Standard for cranes, flamingos, and larger waterbirds.

- 50mm x 50mm (2″ x 2″): Used for large flight displays and poultry protection against hawks.

6. Are There Eco-Friendly Flight Netting Options Available?

In 2026, ecological impact is a major factor in government and non-profit procurement. Stainless steel flight netting is widely considered the most sustainable option on the market.

Eliminating Microplastics

Plastic netting eventually breaks down into microplastics that enter the soil and water. Because stainless steel is an alloy of natural elements, it does not shed harmful chemicals or particles into the environment.

100% Recyclability

Stainless steel is one of the most recycled materials on earth. If an enclosure is ever decommissioned, the mesh can be sold as high-value scrap and melted down to create new steel products, closing the loop on the circular economy.

Reduced Carbon Footprint over Time

While the initial carbon cost of producing steel is higher than plastic, the Life Cycle Assessment (LCA) of stainless steel is superior. Because you only need to install it once every 30 years—compared to replacing plastic every 5 years—the total energy consumption and waste associated with stainless steel are significantly lower.

7. Which Companies Specialize in Custom Flight Netting Installations?

A world-class product deserves a world-class installation. While Hebmetalmesh provides the material, the installation process requires precision.

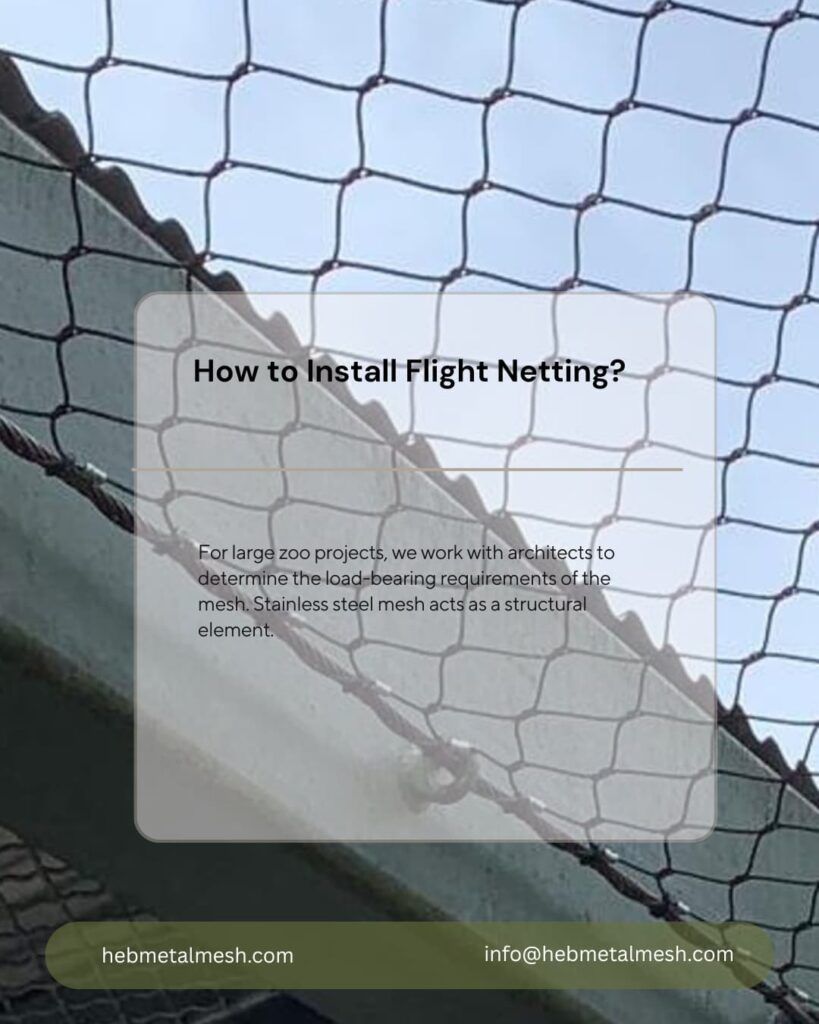

The Role of Architects and Engineers

For large zoo projects, we work with architects to determine the load-bearing requirements of the mesh. Stainless steel mesh acts as a structural element. When tensioned properly, it adds rigidity to the entire frame of the aviary.

Installation Techniques: The “Cable-and-Lace” Method

- Perimeter Cables: A thick stainless steel cable is run between the main support poles.

- Panel Attachment: The flight netting is attached to these cables using “lacing wire” or stainless steel ferrules.

- Seaming: When joining two 30′ x 60′ panels, our technicians recommend “weaving” the two edges together with a single strand of wire. When done correctly, the seam becomes invisible, creating the illusion of a single, continuous piece of mesh covering the entire flight area.

8. Maintenance and Long-Term Care of Flight Netting

One of the greatest selling points of Hebmetalmesh products is that they are virtually maintenance-free. However, for the health of the birds and the longevity of the structure, we recommend a simple annual check-up.

Cleaning Protocols

In bird enclosures, waste and feathers can accumulate in the mesh.

- Zoos: Use a high-pressure water hose once a year to clear away debris. The stainless steel will not rust or degrade from the water.

- Farms: If disinfecting for biosecurity, stainless steel is resistant to most common agricultural cleaning chemicals (unlike nylon, which can be weakened by certain bleaches).

Tension Inspection

Over the first 12 months, a new enclosure may “settle.” We recommend checking the perimeter tensioning every spring. If the mesh looks slightly slack, simply tightening the turnbuckles on your perimeter cables will restore the “drum-tight” finish that makes the netting look professional.

9. Frequently Asked Questions (FAQ)

A: Yes. Because Hebmetalmesh is handwoven, it is incredibly flexible. It can be cut and seamed to fit domes, tunnels, and organic, free-form shapes without losing its structural integrity.

A: Our black oxide process is a chemical conversion of the steel’s surface. It is not a paint or a dip that will flake off. It is highly resistant to scratching and weather, though it may take on a slight “patina” over decades.

A: We recommend measuring the flat surface area of your panels and adding a 5% “buffer” for tensioning and seaming. Better yet, send your drawings to the Hebmetalmesh team, and we will calculate the exact dimensions for your custom rolls.

A: No. Because our mesh is handwoven and flexible, it yields upon impact. This “soft-catch” property is why it is the preferred material for high-speed flight aviaries in professional zoos.

10. Driving Value: The Economic Reality of Flight Netting

When comparing prices, many first-time buyers are tempted by the low cost of synthetic netting. However, a professional analysis shows that Stainless Steel is the cheaper option over a 10-year period.

- Year 1: Plastic is cheaper.

- Year 5: Plastic netting fails; requires labor to remove, cost to buy new netting, and labor to reinstall.

- Year 10: Plastic has been replaced twice. The cost of labor and lost birds (due to escapes or predators) now exceeds the initial cost of a Hebmetalmesh stainless steel system.

By choosing Hebmetalmesh, you are investing in a “set it and forget it” solution.

Conclusion: Partner with Hebmetalmesh for Your Next Project

The world of flight netting is complex, but the solution is simple: High-quality materials, custom manufacturing, and factory-direct pricing. Whether you are protecting a commercial poultry flock or designing a multi-million dollar “walk-through” aviary for a world-class zoo, Hebmetalmesh has the expertise and the inventory to bring your vision to life.

Our commitment to quality—from our use of premium 316-grade steel to our unique black oxide finish—ensures that your enclosure will be safe, beautiful, and enduring.

Take the Next Step

Don’t settle for “off-the-shelf” solutions that don’t fit. Get the exact size you need with no additional cutting fees.

Would you like me to help you calculate the specific mesh requirements for your enclosure dimensions, or should I walk you through the checkout process on our ?

Visit us today at and discover why we are the global leader in stainless steel zoo netting.

Author Bio: This guide was produced by the engineering team at Hebmetalmesh, a leading global manufacturer of handwoven stainless steel wire mesh for zoos, farms, and architectural applications.