Choosing the right stainless steel wire rope mesh can be a daunting task.

With a myriad of factors to consider, from material quality to weave type, the decision-making process can be complex.

This guide aims to simplify that process. It will provide you with the necessary knowledge to make an informed choice.

Whether you’re an architect, a construction professional, or a DIY enthusiast, this guide will help you navigate the world of stainless steel wire rope mesh.

Understanding Stainless Steel Wire Rope Mesh

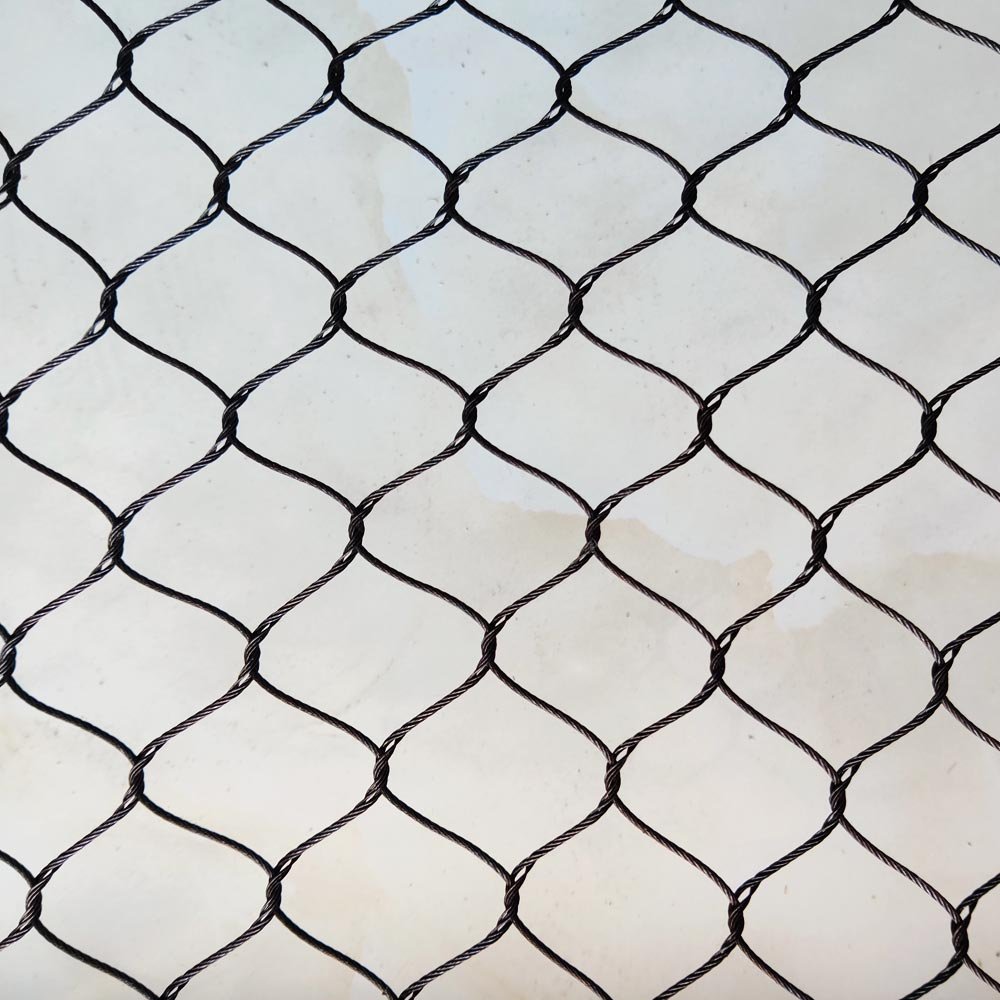

Stainless steel wire rope mesh is a versatile material.

It’s made by weaving together stainless steel wires into a net-like structure.

This mesh is known for its strength, durability, and aesthetic appeal.

It’s also highly customizable, making it suitable for a wide range of applications.

Applications and Benefits

One of the main applications of stainless steel wire rope mesh is in construction.

It’s used for balustrades, safety netting, and even zoo enclosures.

The mesh’s corrosion resistance and tensile strength make it an ideal choice for these demanding applications.

Key Selection Criteria

When choosing a stainless steel wire rope mesh, several factors come into play.

Firstly, consider the quality of the material and its resistance to corrosion.

Next, look at the tensile strength and load-bearing capacity.

Lastly, consider the weave type, flexibility, mesh aperture, and aesthetic appeal.

Material Quality and Corrosion Resistance

The quality of the stainless steel used in the mesh is crucial.

High-quality stainless steel offers excellent corrosion resistance, making it suitable for outdoor applications.

Tensile Strength and Load-Bearing Capacity

The tensile strength of the mesh determines its load-bearing capacity.

A higher tensile strength means the mesh can withstand more weight, making it ideal for safety netting and similar applications.

Weave Types and Flexibility

The weave type affects the flexibility of the mesh.

Ferruled and knotted weaves, for example, offer different levels of flexibility and durability.

Mesh Aperture and Aesthetic Appeal

The size of the mesh aperture affects both functionality and aesthetics.

A smaller aperture may offer more safety, while a larger one can provide a more open and airy aesthetic.

Installation and Maintenance Considerations

Proper installation of the stainless steel wire rope mesh is key to its performance.

Consider factors such as tensioning and anchoring systems during installation.

Installation Best Practices

Ensure the mesh is properly tensioned and anchored during installation.

This will help maintain its shape and functionality over time.

Long-Term Maintenance and Durability

Regular maintenance is essential to ensure the longevity of the mesh.

This includes cleaning and inspecting the mesh for any signs of wear or damage.

Choosing a Reputable Supplier

Selecting a reputable supplier is crucial for a quality product.

Look for suppliers with a proven track record in the industry.

Quality Assurance and Certifications

Ensure the supplier provides quality assurance and necessary certifications.

This guarantees the mesh meets safety and quality standards.