If you’re looking to add an extra layer of security to your metal frames, attaching wire mesh is the way to go. Whether it’s for a garden fence, a window screen, or a protective cage, mastering the art of attaching wire mesh to metal frames is essential. In this step-by-step guide, we’ll walk you through the process, ensuring a strong and durable attachment every time.

First, gather your materials: wire mesh, metal frames, a wire cutter, pliers, and galvanized wire. Measure and cut the wire mesh to fit the frame, leaving a few inches of extra mesh on each side. Next, position the mesh on the frame and use pliers to bend the excess mesh around the frame, creating a secure grip. Once the mesh is in place, use galvanized wire to further secure it, weaving the wire through the mesh and around the frame at regular intervals.

With our comprehensive guide, you’ll master the art of attaching wire mesh to metal frames, adding both security and aesthetic appeal to your projects. Let’s get started!

Keywords: attaching wire mesh to metal frames, step-by-step guide, secure attachment, wire mesh, metal frames, garden fence, window screen, protective cage.

Tools and materials needed for attaching wire mesh to metal frames

When it comes to attaching wire mesh to metal frames, having the right tools and materials on hand is crucial. The first step is to gather all the necessary items to ensure a smooth and successful installation process.

The essential tools you’ll need include a wire cutter, pliers, and a screwdriver or drill. The wire cutter will allow you to trim the wire mesh to the desired size, while the pliers will help you bend and shape the mesh to fit the frame. A screwdriver or drill will be necessary if you choose to secure the mesh with screws.

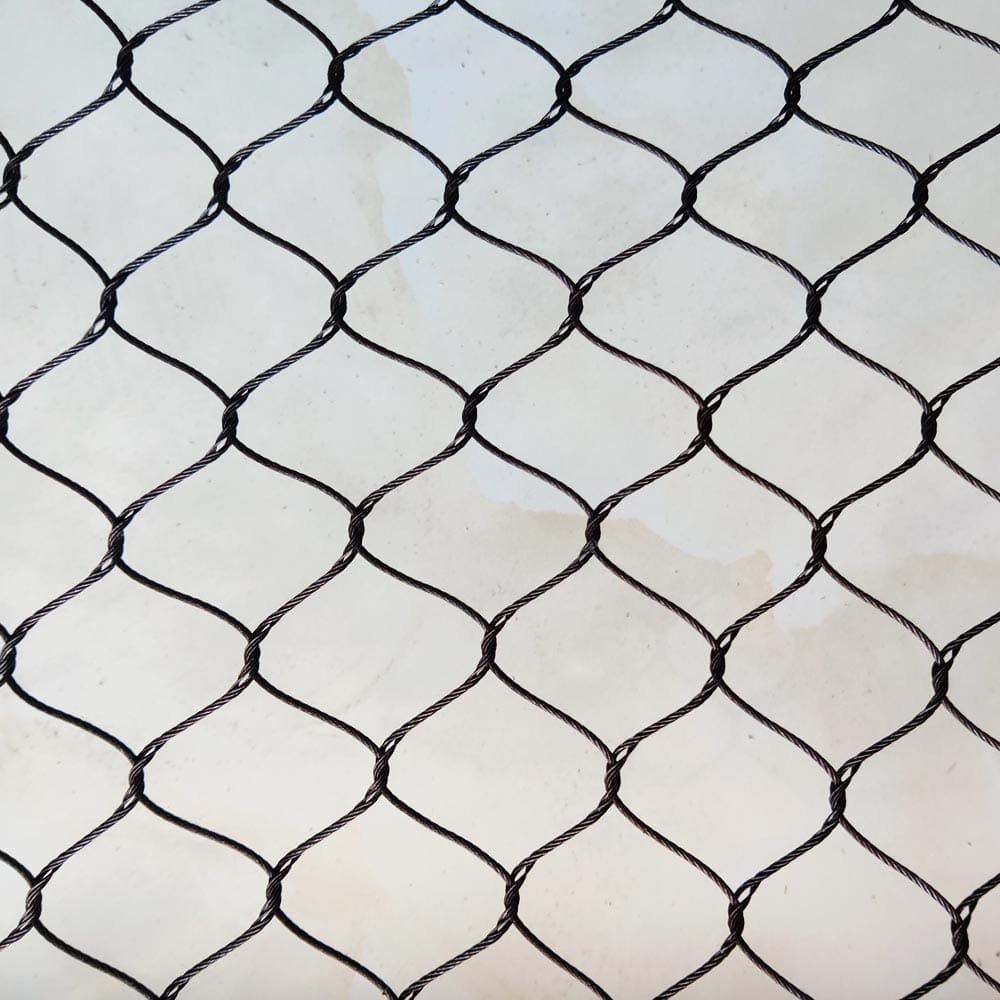

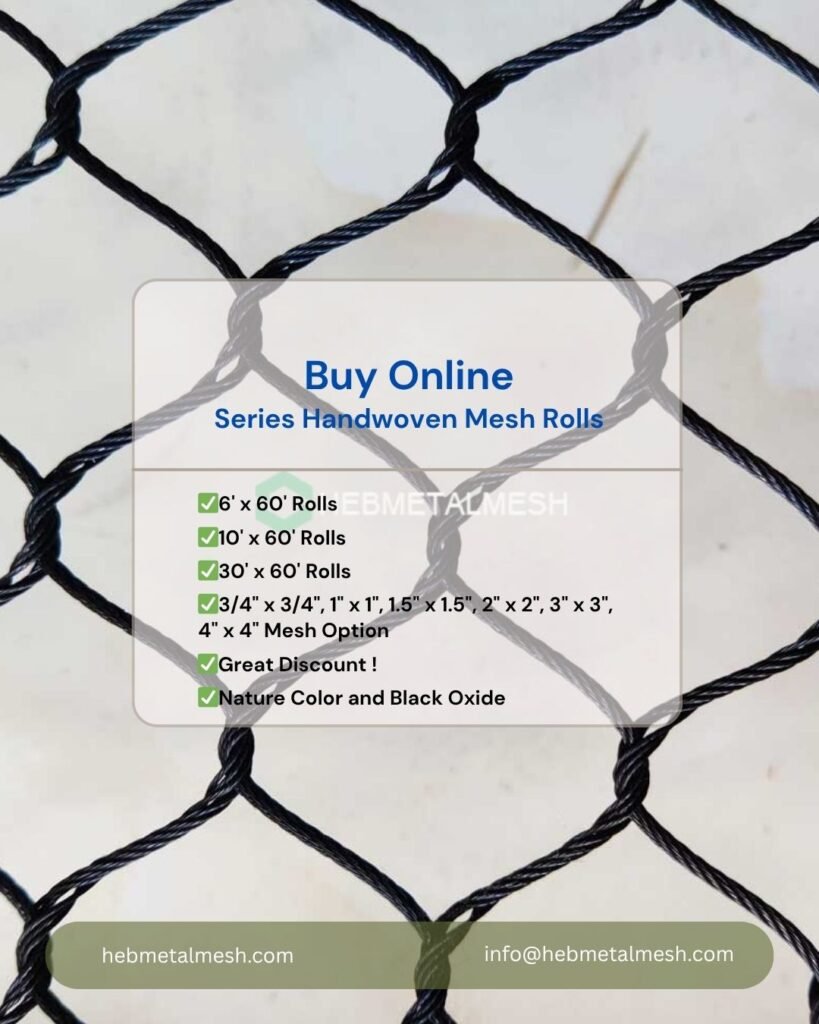

In terms of materials, you’ll need the wire mesh itself, which can come in a variety of sizes and styles depending on your project requirements. You’ll also need galvanized wire or zip ties to securely fasten the mesh to the metal frame. Galvanized wire is a popular choice as it is rust-resistant and durable, ensuring a long-lasting attachment. Additionally, you may want to have some touch-up paint on hand to cover any exposed areas of the metal frame after the installation is complete.

By gathering all the necessary tools and materials beforehand, you’ll be able to work efficiently and minimize any interruptions during the attachment process. Taking the time to ensure you have everything you need will set you up for success and a professional-looking final result.

Preparing the metal frame for wire mesh attachment

Before you can start attaching the wire mesh, it’s important to properly prepare the metal frame. This step will help ensure a secure and long-lasting attachment, as well as a clean and polished final appearance.

First, thoroughly clean the metal frame to remove any dirt, rust, or debris that may be present. This can be done using a wire brush, sandpaper, or a degreasing agent, depending on the condition of the frame. Removing these impurities will help the wire mesh adhere more effectively and prevent any potential issues down the line.

Next, you’ll want to inspect the frame for any sharp edges or protrusions that could potentially damage the wire mesh or pose a safety hazard. Use a file or grinder to smooth out any rough areas, ensuring a clean and even surface for the mesh to be attached to. This step is particularly important if you’re working with an older or reclaimed metal frame.

Finally, consider applying a primer or protective coating to the metal frame before attaching the wire mesh. This will help prevent rust and corrosion, which can compromise the integrity of the attachment over time. Choose a primer or coating that is compatible with both the metal and the wire mesh material to ensure optimal adhesion and durability.

Measuring and cutting the wire mesh to fit the metal frame

Once you have your metal frame prepared, the next step is to measure and cut the wire mesh to the appropriate size. Accurate measurements are crucial to ensure a seamless and secure attachment, so take the time to get this step right.

Begin by carefully measuring the dimensions of your metal frame, taking note of the length, width, and depth. It’s a good idea to measure multiple points along the frame to account for any irregularities or variations in size.

When cutting the wire mesh, it’s important to leave a few extra inches of material on each side to allow for wrapping and securing the mesh to the frame. This extra overlap will provide a stronger and more durable attachment. Use a high-quality wire cutter or snips to ensure clean, straight cuts without any fraying or distortion of the mesh.

If your project requires multiple pieces of wire mesh, be sure to measure and cut each one individually to ensure a precise fit. Trying to use a single, oversized piece of mesh may result in gaps or overlaps that can compromise the overall appearance and stability of the attachment.

Attaching the wire mesh to the metal frame using zip ties

One of the most popular and straightforward methods for attaching wire mesh to metal frames is using zip ties. This versatile fastening solution offers a secure and efficient way to hold the mesh in place, making it a great choice for a wide range of projects.

To begin, position the cut wire mesh on the prepared metal frame, ensuring it is centered and aligned correctly. Starting at one corner, use the zip ties to secure the mesh to the frame, threading them through the mesh openings and around the frame.

When positioning the zip ties, be sure to space them evenly and consistently along the entire perimeter of the frame. This will help distribute the tension and weight of the mesh, creating a strong and stable attachment. Tighten the zip ties firmly, but be careful not to over-tighten, as this could distort or damage the wire mesh.

For added security, you can also weave the zip ties through the mesh in a criss-cross pattern, further locking the mesh in place. This technique is particularly useful for larger or heavier mesh panels, or in applications where the attachment may be subjected to more significant stress or strain.

Alternative methods of attaching wire mesh to metal frames

While using zip ties is a popular and effective method for attaching wire mesh to metal frames, it’s not the only option available. Depending on the specific requirements of your project, you may want to explore alternative attachment techniques to find the best solution.

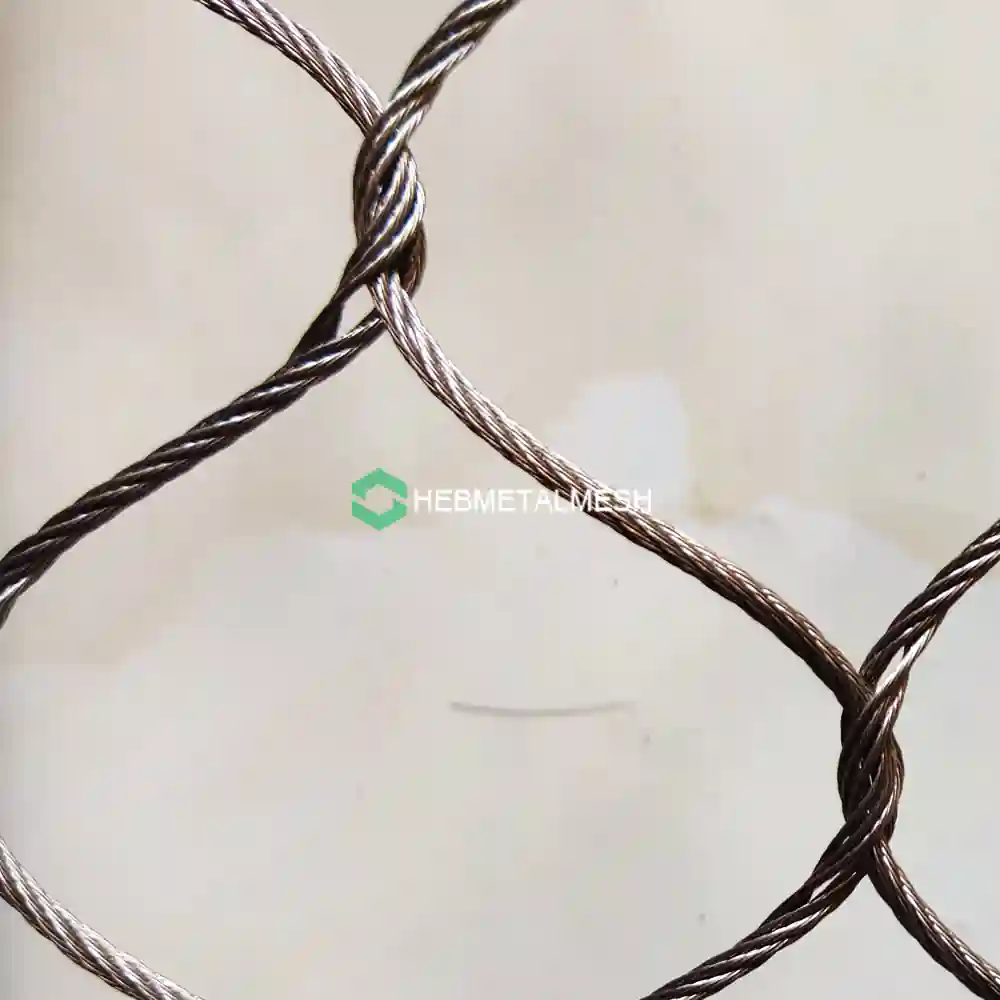

One alternative method is to use galvanized wire or metal clips to secure the mesh. This approach involves weaving the wire or clipping the mesh directly to the frame, creating a more permanent and rigid attachment. This can be particularly useful for applications where the mesh needs to withstand higher levels of stress or impact, such as in industrial or security settings.

Another option is to use adhesives or sealants to bond the wire mesh to the metal frame. This can be a good choice for situations where drilling or penetrating the frame is not desirable, such as when working with delicate or decorative frames. However, it’s important to select an adhesive that is specifically designed for use with both metal and wire mesh materials to ensure a strong and durable bond.

In some cases, you may even choose to weld the wire mesh directly to the metal frame, creating a seamless and highly secure attachment. This approach requires specialized equipment and skills, but can be an excellent choice for projects where maximum strength and durability are paramount.

Securing the wire mesh to the metal frame with staples or screws

While zip ties and alternative attachment methods can be effective, there may be situations where you need a more permanent and secure way to attach the wire mesh to the metal frame. In these cases, using staples or screws can be a reliable solution.

When opting for a staple-based attachment, be sure to use heavy-duty, galvanized staples that are specifically designed for outdoor or industrial applications. These staples will provide a strong, corrosion-resistant hold, ensuring the wire mesh remains firmly in place over time. Start by positioning the mesh on the frame and then use a pneumatic or manual staple gun to secure the mesh at regular intervals along the perimeter.

Alternatively, you can choose to attach the wire mesh using screws. This approach may be preferable if you need to remove or adjust the mesh in the future, as screws can be more easily removed than staples. Use stainless steel or galvanized screws that are compatible with both the metal frame and the wire mesh material. Drill pilot holes to prevent the mesh from tearing, and be sure to tighten the screws securely without over-tightening, which could distort the mesh.

Whichever fastening method you choose, be sure to inspect the attachment periodically and make any necessary adjustments or repairs to maintain the integrity of the wire mesh over time.

Tips for a professional-looking wire mesh attachment

Achieving a professional-looking wire mesh attachment to a metal frame requires attention to detail and a focus on the overall aesthetic. By following a few key tips, you can ensure your finished project not only functions well but also looks visually appealing.

First, pay close attention to the alignment and tension of the wire mesh. Make sure the mesh is evenly taut and centered on the frame, without any noticeable sagging or distortion. This will create a clean, uniform appearance and help prevent any potential issues with the attachment over time.

Additionally, be mindful of the placement and spacing of your fasteners, whether they are zip ties, staples, or screws. Aim for a consistent, symmetrical pattern that complements the overall design of the frame and mesh. Avoid haphazard or irregular placement, as this can detract from the professional look you’re trying to achieve.

Finally, consider the finishing touches that can elevate the appearance of your wire mesh attachment. This may include touch-up paint to cover any exposed areas of the metal frame, or the addition of decorative elements like trim or edging. These small details can make a big difference in the overall aesthetic of your project.

Common mistakes to avoid when attaching wire mesh to metal frames

While attaching wire mesh to metal frames may seem straightforward, there are several common mistakes that can compromise the quality and longevity of the attachment. By being aware of these pitfalls, you can ensure a successful and durable installation.

One of the most frequent mistakes is failing to properly prepare the metal frame before attaching the wire mesh. Neglecting to clean the frame or address any sharp edges can lead to issues with the mesh tearing or becoming damaged over time. Take the time to thoroughly prepare the frame for a secure and long-lasting attachment.

Another common error is inaccurately measuring and cutting the wire mesh to fit the frame. Cutting the mesh too small can result in gaps or overlaps, while cutting it too large can make the attachment process more difficult and lead to a sloppy final appearance. Carefully measure the frame and allow for the appropriate amount of overlap to ensure a perfect fit.

Additionally, using the wrong type of fasteners or failing to secure them properly can compromise the strength and stability of the wire mesh attachment. Be sure to select the appropriate fasteners, whether that’s zip ties, staples, or screws, and follow the manufacturer’s instructions for proper installation to ensure a secure and durable hold.

Conclusion and final thoughts on mastering the art of attaching wire mesh to metal frames

Mastering the art of attaching wire mesh to metal frames is a valuable skill that can be applied to a wide range of projects, from garden fencing to window screens and protective cages. By following the step-by-step guide outlined in this article, you’ll be well on your way to creating strong, secure, and visually appealing wire mesh attachments.

Remember, the key to success lies in proper preparation, precise measurements, and the use of high-quality tools and materials. Take the time to carefully clean and inspect the metal frame, cut the wire mesh to fit perfectly, and select the appropriate fastening method for your specific needs.

Whether you choose to use zip ties, galvanized wire, adhesives, or a combination of techniques, the end result will be a durable and long-lasting wire mesh attachment that adds both functionality and aesthetic appeal to your project. With practice and attention to detail, you’ll soon be able to tackle any wire mesh attachment challenge with confidence and expertise.

So, what are you waiting for? Gather your tools, measure your frames, and get ready to master the art of attaching wire mesh. Your next project is waiting!