In the world of animal husbandry, architectural safety, and industrial containment, the term wire mesh enclosure represents the critical line between security and visibility. Whether you are designing a high-traffic tiger exhibit for a world-class zoo or a backyard aviary for exotic birds, the material you choose determines the lifespan of your project and the well-being of its inhabitants.

As the owner of Hebmetalmesh, I have seen firsthand how the industry has shifted from rigid, high-maintenance fencing to flexible, high-performance solutions. This guide explores everything you need to know about selecting, customizing, and installing the highest-rated wire mesh enclosures on the market today.

Key Takeaways: Selecting the Right Wire Mesh Enclosure

- Superior Durability: Handwoven stainless steel rope mesh offers a 30+ year lifespan, outperforming galvanized and welded wire in extreme weather and high-impact environments.

- Zero-Cost Customization: Hebmetalmesh provides custom roll and panel sizes (up to 30′ x 60′) at no additional fabrication cost, eliminating material waste.

- Safety First: Flexible mesh absorbs impact energy, preventing injury to animals and humans, while the absence of sharp welds protects sensitive plumage and skin.

- Optimal Visibility: Black oxide finishes provide an “invisible” barrier, absorbing light to give visitors an unobstructed view of exhibits.

- Cost-Effective: While the initial investment is higher than traditional fencing, the zero-maintenance and extreme longevity make it the most economical long-term solution.

What is a Wire Mesh Enclosure?

A wire mesh enclosure is a structured containment system made from interlinked metal wires, designed to provide security while maintaining airflow and visibility. The most advanced version is the handwoven stainless steel rope mesh, which offers superior flexibility, a “break-proof” structure, and a lifespan exceeding 30 years. Unlike rigid welded wire, handwoven mesh absorbs impact, making it the safest choice for animal exhibits, bird parks, and heavy-duty industrial safety barriers.

1. The Evolution of Containment: From Iron Bars to Invisible Mesh

To understand why the modern wire mesh enclosure is so effective, we must look at where the industry started. Historically, zoos and animal parks used heavy iron bars or thick chain-link fencing.

The Problem with Traditional Fencing

- Visual Barriers: Thick bars create a “prison-like” atmosphere for visitors, obstructing the view and detaching the public from the nature of the animal.

- Safety Hazards: Rigid bars do not give. If a panicked animal runs into an iron bar, the impact often results in broken bones or severe head trauma.

- Corrosion & Toxicity: Galvanized or painted iron eventually rusts. In a zoo environment, rust isn’t just an eyesore; it’s a health hazard for animals that might chew on the enclosure, leading to heavy metal poisoning.

The Rise of Handwoven Stainless Steel

The introduction of stainless steel wire rope revolutionized the field. By weaving thin but incredibly strong cables into a flexible net, architects were finally able to create “invisible” boundaries. This transition allowed for the creation of immersive exhibits where the boundary between the viewer and the wildlife disappears.

2. Wire Mesh Enclosure vs. Welded Wire Fencing (The Critical Comparison)

When searching for a wire mesh enclosure, you will encounter two primary technologies. Choosing the wrong one can lead to project failure within 24 months.

Welded Wire Fencing for Garden Protection

Welded wire is created by crossing horizontal and vertical wires and welding them at the joints. While cost-effective for simple garden protection or small-scale residential use, it has significant drawbacks for high-stakes environments:

- Rigidity: It is a 2D product. It cannot conform to the organic, 3D curves often required in modern landscape architecture or cave-style exhibits.

- Joint Failure: The weld is the weakest point. Under the constant pressure of a climbing primate or the impact of a large cat, welds can fatigue and snap.

- Injury Risk: Once a weld snaps, it leaves a jagged, needle-sharp point that can snag skin, fur, or feathers.

The Hebmetalmesh Advantage: Handwoven Stainless Steel Mesh

Our signature product is the handwoven stainless steel rope mesh. Instead of welds, our craftsmen manually weave high-strength stainless steel cables into a diamond pattern.

- Elasticity & Energy Absorption: It acts like a trampoline. When an animal hits the mesh, the energy is distributed across the entire panel rather than being concentrated on a single weld.

- Durability: No welds mean no weak points. The structural integrity is maintained by the physical weave and the ferrules (if applicable), ensuring no corrosion begins at the joints.

- Total Customization: Because every panel is handmade, we can produce customized roll sizes tailored to your specific frame with no additional waste or cost.

3. Technical Specifications: Choosing for Industrial and Zoo Use

Understanding the technical data is crucial for safety and budget. At Hebmetalmesh, we categorize our products by three main factors to help you choose the right wire mesh enclosure for industrial or animal use.

A. Cable Diameter (Thickness)

- 1.2mm to 1.5mm (3/64″ – 1/16″): Ideal for small bird aviaries, butterfly houses, and light-duty garden protection.

- 2.0mm to 2.4mm (5/64″ – 3/32″): The standard for medium-sized primates, parrots, and residential “catios.”

- 3.2mm and above (1/8″+): Heavy-duty mesh designed for large predators (lions, tigers, bears) and industrial fall protection.

B. Mesh Aperture (The Opening)

The “hole size” is just as important as the wire thickness.

- 20mm to 40mm: Keeps out small predators like snakes or rats; perfect for protecting prized bird collections.

- 50mm to 80mm: Standard for most zoo exhibits, providing the best balance of strength and visibility.

- 100mm+: Used for large herbivores (giraffes, deer) or as safety netting under bridges and heliports.

C. Rope Construction

We primarily use 7×7 and 7×19 constructions.

- 7×7: Standard flexibility, very popular for architectural and garden use.

- 7×19: Extremely flexible and soft to the touch, preferred for primate enclosures where the animals will be climbing and hanging on the mesh all day.

4. Why Stainless Steel is the “Forever” Solution

At Hebmetalmesh, we prioritize AISI 304 and 316 stainless steel. These are not just “metal” wires; they are engineered alloys designed for extreme environments.

Corrosion Resistance & Chemical Stability

Zoo enclosures are often exposed to:

- Harsh Weather: Heavy UV radiation, snow, and rain.

- Biological Waste: Animal urine and feces can be highly acidic.

- Cleaning Chemicals: High-pressure washers and sanitizers used by keepers. Stainless steel 316 contains molybdenum, which offers maximum resistance to pitting and salt-spray, making it the only choice for coastal bird parks and marine environments.

Aesthetics: Natural vs. Black Oxide Options

- Natural Finish: A classic, bright metallic look that reflects light. It is often used in modern architectural designs, stairwell railings, and garden features.

- Black Oxide: Our most sought-after product for high-end zoos.

- The Invisibility Factor: While light reflects off silver wire, black wire absorbs light. When looking into a black oxide wire mesh enclosure, the human eye focuses past the mesh, creating an immersive experience for visitors.

5. Top Applications: From National Zoos to Backyard Gardens

Zoo Enclosures & Wildlife Parks

The requirements for national zoos are strict: zero failure rates.

- Big Cat Exhibits: Lions and leopards require high-tension security. Our mesh panels are tested to withstand thousands of pounds of force.

- Primate Jungles: For chimpanzees and orangutans, the mesh acts as an extension of their habitat. They can climb it safely without snagging.

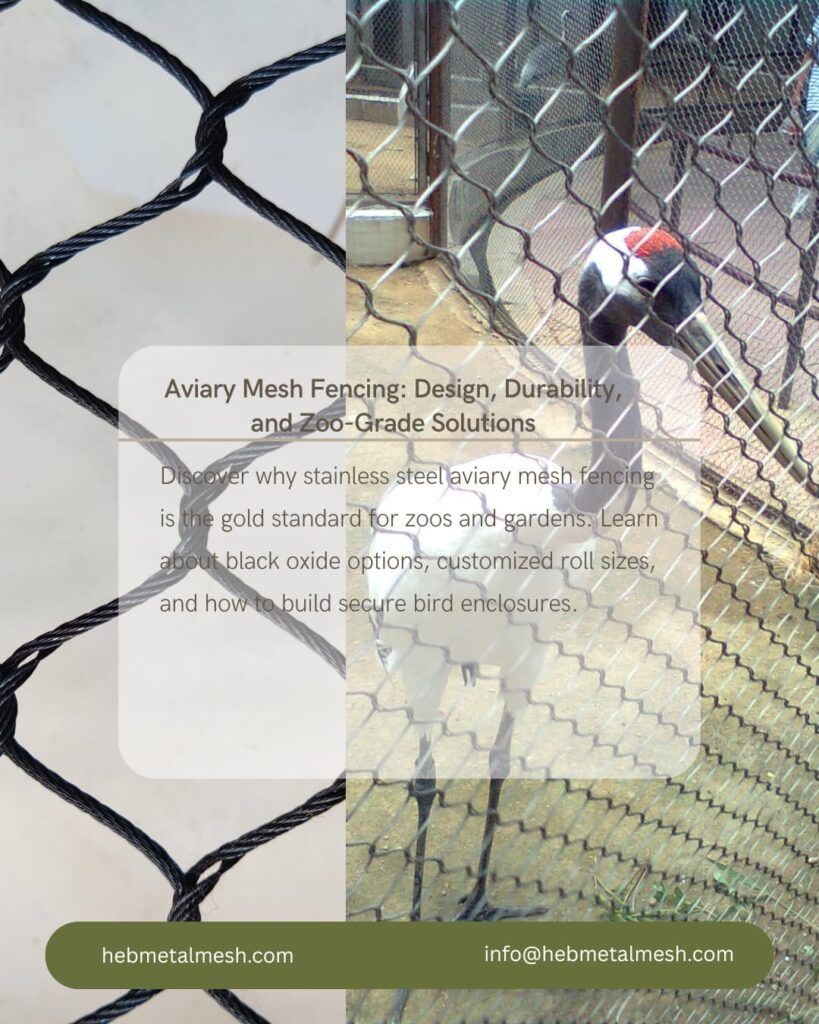

Aviaries and Bird Parks

The safety of a bird’s plumage and beak is paramount. Our handwoven mesh is “beak-friendly.”

- Large Flight Aviaries: Because we can produce massive 30′ x 60′ panels, we can cover huge spans for walk-through aviaries, allowing birds to fly naturally.

- Exotic Species: The small aperture prevents wild sparrows or rats from entering and spreading diseases.

Best Wire Mesh Enclosure Kits for Outdoor Pets

We have seen a massive rise in homeowners wanting zoo-grade quality for their cats and dogs.

- The Catio: A custom cat patio made from our 2.0mm mesh allows cats to enjoy the outdoors safely.

- Heavy-Duty Dog Runs: Perfect for large breeds that can chew through standard chain-link.

6. Custom Wire Mesh Enclosure Fabrication: Why Size Matters

One of the biggest pain points in construction is the waste created by standard roll sizes. If you buy a 10ft roll for an 8ft frame, you are paying for 20% waste.

Hebmetalmesh eliminates this problem.

- Customization is Standard: We don’t charge “extra” to weave a custom size.

- Massive Panel Capability: Our ability to produce single panels up to 30′ x 60′ (9m x 18m) means fewer seams. Fewer seams mean a stronger enclosure and a significantly faster installation process.

7. Cost Comparison: Pre-made Enclosures vs. Custom Builds

Many buyers ask: “Should I buy a pre-made kit or a custom wire mesh enclosure?”

| Feature | Pre-made Kits | Hebmetalmesh Custom Panels |

|---|---|---|

| Initial Cost | Lower | Competitive |

| Material | Often Galvanized/Plastic | 100% Stainless Steel |

| Installation | High labor (cutting/joining) | Low labor (fits perfectly) |

| Lifespan | 3–7 Years | 30+ Years |

| Waste | 15–20% scrap | 0% scrap |

The “Cheap” Trap: A galvanized mesh enclosure will require replacement every few years due to rust and zinc toxicity. Hebmetalmesh is the far more economical choice over a 10-year period.

8. Where to Buy Heavy-Duty Wire Mesh Enclosures Near Me?

With our factory-direct model, we have simplified the process of getting world-class mesh to your site, whether you are in North America, Europe, or Australia.

- Direct Factory Pricing: By cutting out the middleman, we pass the savings directly to you.

- Online Store Accessibility: You can browse our most popular sizes and wire diameters at the Hebmetalmesh Store.

- Fast Global Shipping: Because the mesh is flexible and compressible, shipping large 30′ x 60′ panels is surprisingly affordable and efficient.

9. Comprehensive Installation Guide

A wire mesh enclosure is only as good as its installation.

Phase 1: Frame Preparation

Ensure your support structure is rigid. We recommend using stainless steel tubing or high-tension perimeter cables.

Phase 2: Attaching the Mesh

- Temporary Positioning: Use zip-ties to loosely hang the mesh panel.

- Lacing: Use the provided lacing wire to “sew” the edge of the mesh to the frame. Wrap around the frame and through every mesh diamond.

- Tensioning: Work from the center outward to ensure the diamond pattern is uniform and tight.

10. Frequently Asked Questions (FAQ)

For smaller monkeys, we recommend a 1″ x 1″ opening. For larger primates, a 2″ x 2″ or 3″ x 3″ opening with a 3.2mm cable is standard.

Absolutely. Our mesh is widely used for industrial fall protection, safety partitions in warehouses, and bridge safety netting.

Yes. Unlike galvanized wire which can cause zinc poisoning, our stainless steel black oxide process is non-toxic and will not flake off when chewed.

11. Conclusion: Your Expert in Wire Mesh Enclosure Solutions

A wire mesh enclosure is more than just a fence; it is a critical component of safety, animal health, and architectural beauty. At Hebmetalmesh, we take pride in being a factory that understands the needs of our customers—from the largest international zoos to the individual garden enthusiast.

Ready to transform your project?

- Explore our full range: Hebmetalmesh Home

- Check prices and buy online: Hebmetalmesh Store

- Request a Custom Quote: Contact our team for specialized projects and large-scale panels.