Pliable, transparent grid structures made of stainless steel rope from Hebmetalmesh series are multifunctional and durable,100% Hand Woven, Strong, Flexible, Soft, Durable, No Rust, No Corrosion, Useful Life Over 30 Years…

About Multiple choices for stainless steel zoo mesh, factory sales handwoven stainless steel netting, zoo mesh manufacturer

Pliable, transparent grid structures made of stainless steel rope from Hebmetalmesh series are multifunctional and durable, Hebmetalmesh handwoven stainless steel netting was subjected to numerors tests and complies with all applicable standards: as a permanent protective and safety mesh for zoo mesh, animal enclosures, bird aviary, it is absolutely UV- and weather-resistand,100% Hand Woven, Strong, Flexible, Soft, Durable, No Rust, No Corrosion, Useful Life Over 30 Years.

Hebmetalmesh handwoven stainless steel netting has the skin-like characteristics of diaphragm, it can from a plane surfae but can also be tensioned into three-dimensional forms featuring funnel-type, cylin-drical, or spherical shapes.

Introduce Multiple choices for stainless steel zoo mesh, factory sales handwoven stainless steel netting, zoo mesh manufacturer- hebmetalmesh

HEBEI KETONG METAL MESH INDUSTRY CO. LTD is professional manufacturer of hand woven stainless steel netting from China, Hebei Metal Mesh Ltd announces to supply custom-made zoo enclosure fence netting, bird control netting and animal fence enclosures netting, and nettings for other applications.

Multiple choices for stainless steel zoo mesh, factory sales handwoven stainless steel netting, zoo mesh manufacturer superiority:

1. Large mesh panel design, for many years, we continuously improve production process, now we can manufacture more than 2,000 sq.ft mesh panel, some specification can manufacture more than 3,000 sq.ft.! And there is no any joint in the middle. Great convenience to users.

2. Ordering production processes, production according to the user’s requirements, you can get every piece of mesh size is suitable for your design, do the zero waste, can most save your cost.

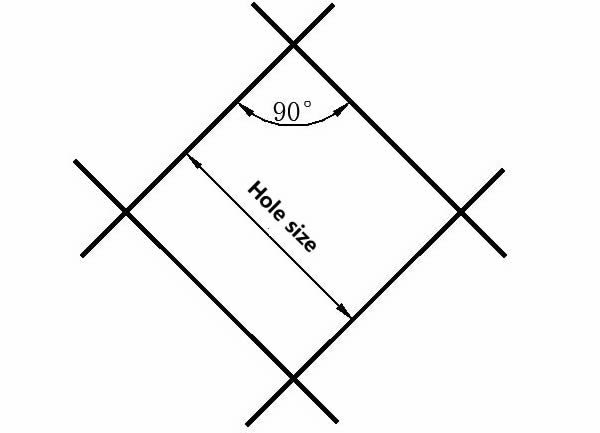

3. We adopt precision mould, ensure mesh size accord with standard, every mesh knot cross woven by hand, ensures that each mesh, each mesh knot never deformation.

4. Installation is concise, because every piece of mesh are manufactured according to the requirement, this will make mesh in line with the framework, make installation is very simple.

5.Material guarantee, Size guarantee, Quality assurance, On time delivery guarantee!

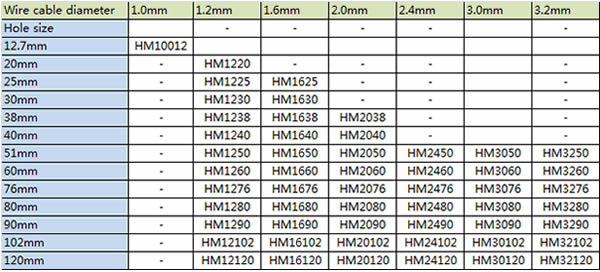

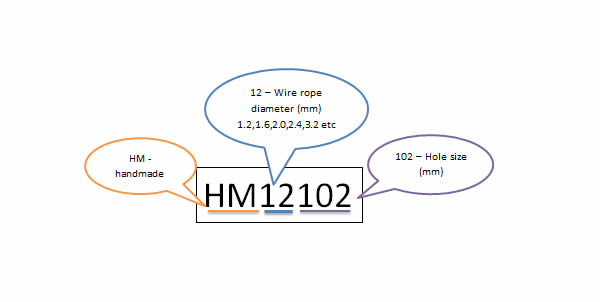

Multiple choices for stainless steel zoo mesh, factory sales handwoven stainless steel netting, zoo mesh manufacturer:

Contact us now:

Sales manager: Mr. Steven

Chat with us on website our leave a message;

Sent Email: info@hebmetalmesh.com

Message with Whatsapp: +8615530133907

Message with Wechat: x15530133907