Premium Zoo Netting Solutions – Factory-Direct Stainless Steel Security by Hebmetalmesh

Securing animal enclosures demands industrial-grade netting that prioritizes welfare, longevity, and escape prevention. As a factory-direct manufacturer, Hebmetalmesh delivers precision-engineered stainless steel zoo netting in nature-mimic green and low-visibility black oxide—customized to your enclosure’s exact dimensions for zoos, sanctuaries, and wildlife parks worldwide.

Why Professionals Trust Our Factory Solutions

✔ Zero-Corrosion Guarantee: 316L marine-grade stainless steel resists urine, salt, and chemicals (exceeds AZA Material Standards).

✔ Custom-Fit Rolls: Unlimited widths/lengths with reinforced selvage edges (no weak seams).

✔ Welfare-Focused Colors:

- Nature Green: Blends with foliage to reduce animal stress (per RSPCA Enrichment Guidelines).

- Black Oxide: Non-reflective surface prevents avian collisions (American Bird Conservancy).

Authority-Backed Performance

“Stainless steel mesh with ≥4mm wire diameter prevents big cat escapes and injuries.”

– Global Federation of Animal Sanctuaries (GFAS) Standards

“Customizable barrier rolls reduce installation waste by 30% versus panels.”

– Association of Zoos & Aquariums (AZA) Sustainability Report

Applications Beyond Traditional Zoos

- Primate Canopy Covers: Anti-climb tension systems (6mm cables, 50x100mm mesh).

- Avian Flight Domes: Feather-safe knotted designs (UV-stabilized for 15+ years).

- Marine Mammal Barriers: Saltwater-proof mesh for tidal enclosures.

Your Factory Advantage

→ Direct Pricing: Eliminate distributor markups (30–50% savings).

→ Certified Compliance: Documentation for AZA, GFAS, EAZA, and USDA audits.

→ Technical Support: On-call engineers for load calculations and CAD layouts.

This guide reveals how Hebmetalmesh’s factory-direct netting transforms enclosures into ethically compliant, escape-proof habitats—where animal welfare and keeper safety unite through precision manufacturing.

Introduction to Zoo Netting

Zoo netting is an essential component in the design and maintenance of animal enclosures, serving both protective and aesthetic functions within zoological settings. Its primary purpose is to create a safe, secure environment for animals, protecting them from potential dangers while ensuring the safety of visitors. This type of netting is commonly constructed from durable materials, such as high-strength polypropylene or nylon, designed to withstand the elements as well as the physical stresses imposed by animals.

The applications of zoo netting are diverse, encompassing not only animal enclosures but also aviaries, reptile habitats, and aquatic exhibits. As conservation efforts grow more pressing in the face of habitat loss and climate change, the role of zoo netting becomes even more vital. It not only helps to maintain animal populations in controlled environments but also facilitates breeding programs aimed at restoring endangered species. By limiting the interaction between captive wildlife and external threats, zoo netting ensures that animals can thrive in their enclosures while minimizing stress and behavioral issues.

Furthermore, zoo netting enables visitors to observe animals in a more naturalistic setting, thereby enhancing their experience while fostering engagement with conservation efforts. For instance, the strategic placement of zoo netting can create immersive habitats replicating the animals’ natural environments, allowing guests to appreciate wildlife from a safe distance without disturbing their ecological balance. The transparent nature of some netting materials allows for unobstructed views while providing a secure barrier. In doing so, it fulfills an important role in wildlife education and raising awareness about the significance of animal conservation.

Why Choose Hebmetalmesh for Your Zoo Netting Needs?

When it comes to selecting a provider for zoo netting, Hebmetalmesh stands out as a reputable manufacturer known for its commitment to quality and innovation. With years of experience in the field, the company has developed a strong reputation for producing zoo netting solutions that not only meet but often exceed industry standards. This experience ensures that clients benefit from the extensive knowledge and expertise that Hebmetalmesh brings to each project.

Quality is at the forefront of Hebmetalmesh’s manufacturing process. The company utilizes advanced materials and technologies to create zoo netting that is durable, safe, and resilient against various environmental factors. Clients can trust that the zoo netting products from Hebmetalmesh are designed to endure the rigors of outdoor environments while providing maximum safety for the animals and peace of mind for the caretakers.

Moreover, Hebmetalmesh prides itself on its exceptional customer service. The company understands that each zoo enclosure has unique requirements, and they work closely with clients to design and implement customized zoo netting solutions that fit specific needs. This tailored approach ensures that the enclosures not only function effectively but also enhance the overall aesthetic of the zoo environment.

Hebmetalmesh’s commitment to innovation is also noteworthy. The company continuously invests in research and development to enhance its zoo netting products, integrating new technologies that allow for improved safety and longevity. This focus on innovation ensures that clients are receiving the most advanced solutions available in the market today.

In conclusion, choosing Hebmetalmesh for zoo netting needs guarantees a reliable partnership that prioritizes quality, exemplary customer service, and innovative solutions tailored to the complexities of modern zoo environments.

The Materials Behind Quality Zoo Netting

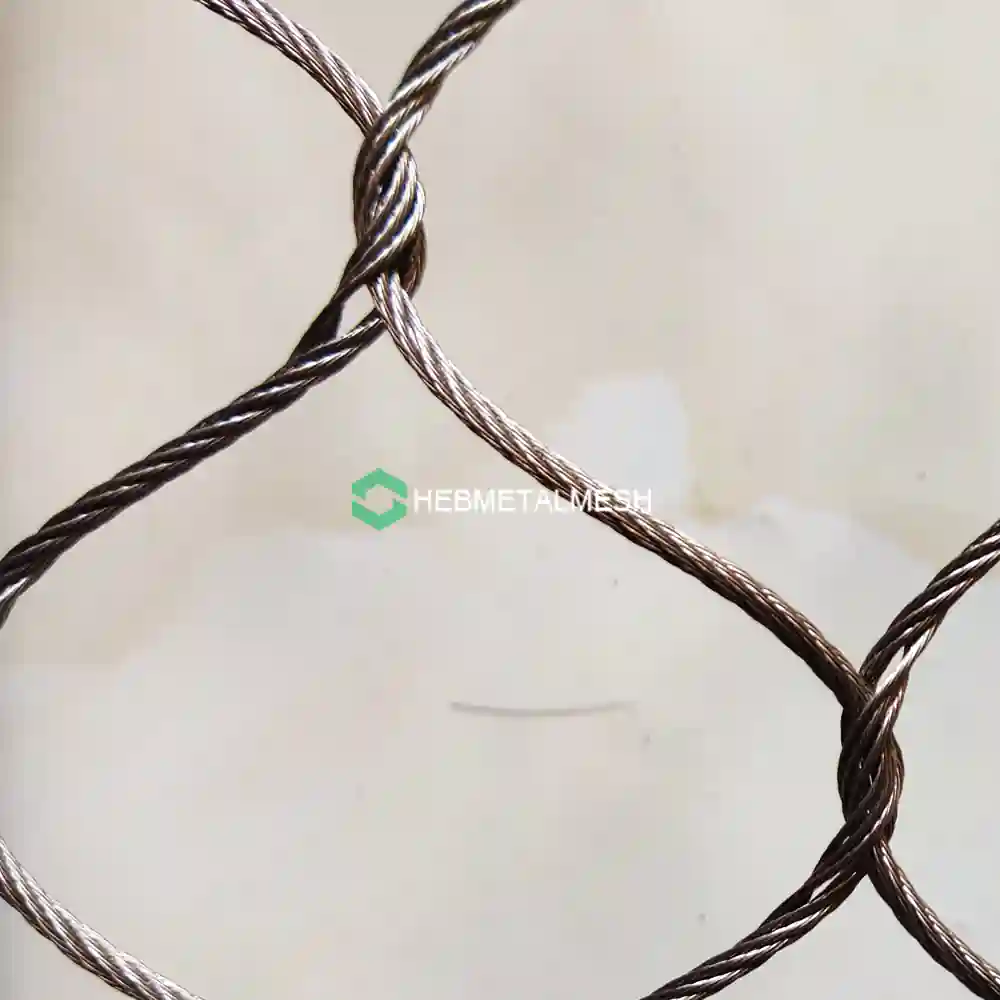

Zoo netting is an essential component for animal enclosures, ensuring safety for both animals and visitors. One of the primary materials used in the production of high-quality zoo netting is stainless steel, often enhanced with a black oxide finish. The choice of materials significantly influences the durability and performance of the netting in outdoor environments, which can expose it to varied weather conditions.

Stainless steel is favored for its exceptional strength, allowing it to withstand not only the weight and stress of environmental factors but also the activities of the animals it contains. The black oxide coating provides additional benefits, offering improved corrosion resistance compared to untreated stainless steel. This is particularly important as the netting is frequently subjected to rain, humidity, and fluctuations in temperature, which could otherwise lead to the rapid degradation of lesser materials.

One of the standout features of zoo netting made from stainless steel with a black oxide finish is its longevity. Properly installed and maintained netting can last up to 20 years, providing an enduring solution for wildlife enclosures. This longevity ensures that facilities can invest in a reliable infrastructure without the recurring costs associated with frequent replacements. Furthermore, the visual appeal of black oxide stainless steel does not detract from the natural environment, allowing for an unobtrusive enclosure that maintains the aesthetic qualities of the zoo.

In addition to stainless steel, other materials may be utilized in zoo netting production, such as synthetic fibers or coated wires. However, none offer the same level of durability and weather resistance as stainless steel. Therefore, it is vital for zoo managers and architects to consider the material properties when selecting netting solutions to ensure a safe and effective environment for the animals and visitors alike.

Applications of Zoo Netting: Enclosures and Aviaries

Zoo netting has become an essential component in contemporary wildlife management, offering a versatile solution for various applications, particularly in animal enclosures and aviaries. The unique properties of this netting, such as its durability, transparency, and flexibility, enable zoos and wildlife parks to create safe and secure environments for animals while ensuring the viewing pleasure of visitors.

One of the primary applications of zoo netting is in animal enclosure fences, where it serves not only as a physical barrier but also as a means of comfort for the animals. For instance, large predators like lions or tigers are often contained within robust netting systems that allow natural ventilation and light while minimizing stress caused by confinement. The netting’s configuration permits animals to exhibit natural behaviors, ensuring their well-being while providing safety to both wildlife and visitors.

Aviaries represent another significant application of zoo netting, where maintaining a balanced ecosystem is crucial. Enclosures designed for birds often utilize specialized bird netting, which allows for maximum visibility and airflow while protecting the avian inhabitants from potential threats. Many zoos have successfully implemented such systems, demonstrating how netting can foster environments conducive to the needs of different bird species. For example, the San Diego Zoo’s aviary utilizes netting to create spacious, interactive habitats, promoting the birds’ natural flying capabilities within a safe environment.

Furthermore, zoo netting’s adaptability extends to various other settings, including temporary event setups or seasonal exhibits. This flexibility makes it an invaluable asset for zoos seeking to balance aesthetics, safety, and animal welfare across a range of settings and applications. By integrating zoo netting into their design framework, wildlife parks can effectively enhance both operational safety and the overall visitor experience while promoting the health of resident species.

Understanding The Manufacturing Process at Hebmetalmesh

At Hebmetalmesh, the manufacturing process of zoo netting is a meticulously structured operation that integrates advanced technologies with strict quality control protocols. The journey begins with the selection of high-grade raw materials, specifically designed to withstand various environmental conditions. This selection process is critical, as it dictates the durability and reliability of the final product, ensuring it meets the standards required for animal enclosures.

The next step involves the use of state-of-the-art machinery, which is crucial in shaping, cutting, and weaving the netting into the desired specifications. Utilizing computerized weaving machines allows for precise control over the mesh size and strength, ultimately contributing to the durability of the zoo netting. Additionally, these machines can produce varying mesh configurations that cater to different animal types and enclosure designs, emphasizing the versatility of the products offered.

Hebmetalmesh places significant emphasis on quality control throughout the production stages. Each batch of zoo netting undergoes a series of rigorous tests to ensure it meets safety and durability standards. These tests assess tensile strength, resistance to weathering, and overall structural integrity. This commitment to quality ensures that the zoo netting can protect both the animals and the visitors, as well as withstand the elements over time.

Furthermore, the manufacturing process at Hebmetalmesh is underpinned by sustainable practices. The company strives to reduce its environmental footprint by implementing energy-efficient processes and recycling excess materials whenever possible. This not only supports global sustainability efforts but also enhances the overall quality of the zoo netting, as responsibly sourced materials often yield superior products. Thus, every step of the production process at Hebmetalmesh reinforces its mission to provide high-quality, reliable zoo netting designed to enhance animal welfare and safety in enclosures.

Customer Success Stories: Trust Built Over 30 Years

Over the past three decades, Hebmetalmesh has established a strong reputation in the industry, providing high-quality zoo netting solutions to over 100 zoos and bird parks around the world. The company has continuously prioritized customer satisfaction, resulting in testimonials that showcase the effectiveness and reliability of their products.

One noteworthy example comes from the renowned San Diego Zoo, which faced significant challenges in securing enclosures for various species, particularly those known for their agility and intelligence. After implementing Hebmetalmesh’s advanced zoo netting, the team reported an immediate improvement in both safety and aesthetic appeal. The zoo’s management highlighted how the netting not only kept the animals secure but also allowed visitors to appreciate the natural behaviors of the animals without obstructions.

Another success story emerged from an exotic bird park in Florida. The park required a solution that would ensure the safety of its diverse bird population while also allowing them to fly freely. The installation of zoo netting proved to be a game changer. The director expressed gratitude for the product’s durability and weather resistance, which has withstood the test of time against harsh climatic conditions. This transformation was pivotal in attracting more visitors, who were now able to see the birds in a secure yet open environment.

Furthermore, a wildlife sanctuary in Australia found that the zoo netting from Hebmetalmesh allowed them to expand their animal habitats. With its reliable mesh design, the netting maintained animal safety while also blending seamlessly with the natural surroundings, providing an enriching environment for both the animals and their visitors. Thus, over the years, these cases exemplify the trust customers have placed in Hebmetalmesh’s zoo netting solutions, further solidifying the company’s legacy in enhancing animal welfare across diverse settings.

Maintaining Your Zoo Netting for Longevity

The longevity of zoo netting is crucial for the well-being of animals and the overall safety of zoo enclosures. Proper installation and maintenance are essential practices that zoo managers must prioritize to ensure that netting systems remain effective over time. Regular inspections should form the backbone of any maintenance regime. These inspections enable the identification of wear and tear early, ensuring that minor damages do not escalate into major issues. Keeping a log of these inspections helps track the condition of the netting, making it easier to plan for repairs and replacements.

In addition to inspections, cleaning zoo netting is equally significant. Natural debris, such as leaves, dirt, and bird droppings, can degrade the material’s integrity if left unattended. It is advisable to schedule regular cleanings, utilizing gentle washing techniques to avoid chemical damage. Water pressure should be moderated, and harsh cleaning agents should be avoided to maintain the structural soundness of the netting. In situations where algae or fungi begin to grow, it may be necessary to seek specialized cleaning products designed for netting to safely address these issues.

Zoo managers should also pay attention to environmental factors that may contribute to the netting’s wear. For instance, UV exposure can lead to material degradation over time. Implementing shaded areas or using UV-resistant netting can significantly extend the lifespan of your installations. Furthermore, monitoring the tension of the netting system is vital; overly taut netting can lead to tearing, while insufficient tension may compromise the enclosure’s security. Regular adjustments can ensure that netting remains adequately supported. By adhering to these maintenance practices, zoos can invest wisely in the longevity of their netting, supporting both animal welfare and visitor safety.

Hebmetalmesh Zoo Netting: Frequently Asked Questions

A: Our heavy-duty stainless steel zoo containment netting offers superior corrosion resistance against weather, UV exposure, and animal waste. Unlike galvanized alternatives that rust and flake, it provides a lifelong safety solution for zoo habitats – critical for primates, aviaries, and marine exhibits where structural failure risks animal escapes or injuries.

Q2: Can you customize netting for specialized exhibits like walk-through aviaries or reptile domes?

A: Absolutely. As a factory-direct manufacturer, Hebmetalmesh specializes in custom wildlife enclosure netting solutions. We tailor rolls to your exact specifications:

Mesh density: 1″ to 4″ openings

Wire diameter: 1.2mm–3.2mm (3/64″ -1/8″)

Color (natural stainless or black oxide)

Tensile strength (up to 1,500 lbs)

Perfect for architectural zoo mesh for curved exhibits or shark tank reinforcement netting.

A: Yes. Our low-visibility black oxide animal barrier netting blends seamlessly into foliage and shadows, minimizing visual intrusion for immersive exhibits. Ideal for aesthetic zoo enclosures in botanical gardens or safari parks where guest experience is prioritized, while maintaining the same strength as natural stainless steel.

A: Engineered for vandal-resistant zoo containment systems, our 304/316 stainless steel resists chewing, clawing, and impact. The handwoven construction and reinforced edges provide bite-proof netting for destructive animals, outperforming poly ropes or chain links that fray or deform under sustained force.

A: While we focus on manufacturing, every order includes:

Custom netting rolls with tensioning hardware kits

Zoo exhibit installation technical manuals

Engineering consultation for complex projects

For turnkey zoo exhibit containment systems, we partner with certified installers experienced with Hebmetalmesh products globally.

Zoo netting is an essential component of modern wildlife enclosures, and several common questions arise regarding its application, installation, and features. One frequent inquiry pertains to the installation costs associated with zoo netting. The expense can vary widely based on factors such as the type of netting chosen, the size of the enclosure, and the specific requirements of the animal species being accommodated. While high-quality materials may come at a premium, investing in durable zoo netting is crucial to ensure the safety and well-being of both the animals and the visitors.

Another prevalent concern revolves around the customization options available for zoo netting. Many manufacturers offer tailored solutions to meet specific needs. Options may include various mesh sizes, colors, and tensile strengths, allowing facilities to customize netting according to the particular species’ behavior and habitat requirements. This customization ensures that the enclosures not only serve their primary function but also aesthetically blend into the environment, providing a more natural setting for the animals.

Safety features are paramount when it comes to zoo netting. Zoos and wildlife facilities must adhere to strict safety standards to prevent animal escapes and ensure public safety. High-strength tensile materials often feature in the construction of zoo netting, along with design considerations that mitigate risks. Additionally, those charged with maintaining these enclosures should routinely inspect the netting for any wear and tear, promoting a safe habitat for inhabitants.

Lastly, compliance with international zoo standards is often a point of concern. Organizations like the World Association of Zoos and Aquariums (WAZA) provide guidelines that impact the choice and installation of zoo netting. Adhering to these standards ensures that enclosures meet global expectations for animal welfare and environmental sustainability, creating a sanctuary that respects the natural instincts and behaviors of its residents.

Conclusion: The Future of Zoo Netting with Hebmetalmesh

As we reflect on the evolving landscape of animal enclosures, it becomes evident that zoo netting plays a crucial role in ensuring the safety and well-being of wildlife while promoting an immersive experience for visitors. Hebmetalmesh has emerged as a leader in the field, offering innovative solutions that enhance both functionality and aesthetics in animal habitats. Their commitment to excellence in manufacturing and design sets a new benchmark for zoo netting, paving the way for future advancements.

One of the key advantages of Hebmetalmesh’s offerings is the integration of durable materials that withstand the test of time and environmental factors. The company employs advanced manufacturing techniques that ensure the netting is not only resilient but also minimally invasive to the natural behaviors of the animals. By using materials that provide safety without obstructing views, Hebmetalmesh assists zoos in creating an authentic environment that mirrors the animals’ natural habitats. This balance between safety and realism is vital for both animal welfare and visitor engagement.

Looking ahead, the potential for innovation in zoo netting technology is considerable. With ongoing research and development, we can anticipate new materials that may offer enhanced durability, visibility, and ease of installation. These advancements could lead to a better understanding of animal behaviors and improved interactions between visitors and wildlife. By staying ahead in quality, Hebmetalmesh ensures that zoos are equipped with the best tools to protect their animals while enhancing educational opportunities for the public.

In conclusion, Hebmetalmesh has established itself as a frontrunner in the provision of zoo netting solutions, emphasizing both safety and aesthetic appeal. As we move toward the future, the continued development of cutting-edge materials and designs will be critical in supporting the evolving needs of zoos around the world, ensuring that both animals and visitors can thrive in a secure and engaging environment.