Introduction: What is Mesh Netting?

From protecting a tiny seedling in your garden to containing majestic animals in a zoo, or ensuring safety netting on a high-rise construction site, mesh netting is an invisible hero in our everyday world. This simple yet sophisticated material provides a critical barrier or boundary, often without obstructing light or airflow.

At its core, mesh netting is an open-meshed material—made from interwoven or knitted fibers, ropes, or wires—designed to protect, divide, filter, or secure an area. It’s used in countless applications, providing containment without the visual or physical bulk of a solid wall. The sheer versatility of netting is why it’s found everywhere, from your local park to the most advanced architectural designs.

But here’s the challenge: with so many types of mesh netting available—from delicate polyester threads and UV-treated nylon to rugged polyethylene (PE) and industrial-grade stainless steel cable—how do you choose the right one? Choosing the wrong material or construction type can lead to costly failure, frequent replacement, and severe safety risks that no one can afford to take.

This definitive guide will explore every facet of wire mesh netting. We’ll cover all common materials and their uses, providing you with the knowledge needed to make an informed choice. Most importantly, we will introduce you to the heavy-duty world of handwoven stainless steel mesh—the permanent, high-strength solution for your most demanding, heavy-duty projects. You will learn why this material is rapidly becoming the industry standard for high-security aviary netting, reliable construction netting, and high-end architectural infill.

Chapter 1: Understanding the Basics – The Key Characteristics of Mesh Netting

Before diving into specific types, it’s essential to understand the core characteristics that define the performance and suitability of any netting material. By evaluating these factors, you can accurately assess whether a net is appropriate for its intended use, especially in critical applications requiring high safety netting standards.

1. Material Composition

The base material is the most important factor, dictating the net’s strength, durability, and resilience.

- Polymeric Materials (Polyester, Nylon, Polyethylene, Polypropylene): These nets offer flexibility, light weight, and affordability. They are suitable for temporary or non-load-bearing applications, but their strength and resistance to long-term environmental factors are limited.

- Metallic Materials (Stainless Steel): This category, particularly high-tensile stainless steel mesh cable, provides superior strength, durability, and crucial fire resistance. The SS304 and SS316 alloys ensure maximum corrosion resistance and a lifespan measured in decades.

2. Mesh Size & Opening

This is defined by the distance between the interwoven nodes or cables. It directly dictates what the net will contain or exclude, making it critical for specialized applications.

- Ultra-Fine Mesh: Necessary for insect barriers or very fine filtration.

- Small Openings: Crucial for small bird netting applications, human fall protection, or containing small animals.

- Large Openings: Suitable for architectural railing infill, decorative facades, or large animal containment where transparency and flexibility are key. Choosing the right mesh size is a fundamental safety and functional consideration.

3. Strength & Load Capacity

This is the most crucial characteristic for heavy duty netting and high-risk safety applications. Strength is measured primarily by tensile strength (the force required to pull it apart) and breaking strength (the point of catastrophic failure).

Polymeric nets often rely on knotting for strength, which can introduce weak points. In contrast, high-tensile stainless steel cable netting is structurally engineered to offer immense load capacity required for high-impact applications, large animal containment, or structural safety roles.

4. Durability & Lifespan

Durability is an evaluation of how the material resists long-term wear and environmental factors.

- UV Resistance: Vital for any outdoor net, preventing the material from becoming brittle, weakening, and eventually disintegrating under sun exposure.

- Rot Resistance: Essential for nets used in contact with soil or water, such as garden netting or aquaculture applications.

- Corrosion Resistance: Absolutely necessary for metal nets, especially in humid or marine environments. This is where high-grade SS304/316 excels.

Cheap netting often requires frequent, costly replacement, leading to unplanned labor and recurring material expenses. Materials like high-grade stainless steel offer lifespans of 20+ years, making them a permanent fixture rather than a disposable item.

5. Flexibility vs. Rigidity

This characteristic affects both installation and the application’s final look.

- Highly Flexible Nets: Materials like soft nylon or handwoven steel cable conform easily to irregular, three-dimensional shapes (e.g., dome zoo enclosures or sloping landscape boundaries).

- Rigid Nets: Typically welded wire mesh, used for flat, fixed panels such as standard square-section fencing. While strong, they lack the adaptable, fluid aesthetic of flexible cable nets.

6. Breathability & Light Permeability

Often overlooked, these factors are especially important for agricultural uses and architectural facades. Netting must allow sufficient light transmission and air circulation. Poor breathability can lead to plant rot or create heat traps behind building facades. A cable net structure maximizes light and air movement while providing robust containment.

7. Cost vs. Long-Term Value

The sticker price of a basic plastic garden netting is low, but this is deceptive. When calculating the true cost, one must factor in maintenance, replacement cycles (the cost of labor to remove and reinstall a failed net), and the potential cost of failure. A higher initial investment in a durable, permanent material like stainless steel mesh results in a significantly lower Total Cost of Ownership (TCO) over two decades, making it the financially smarter long-term choice.

Chapter 2: A Deep Dive into Common Types of Mesh Netting

To truly understand the value of premium wire mesh netting, it helps to examine the alternatives. Here, we break down the most common materials, their best uses, and their inherent limitations.

2.1. Polyester & Nylon Mesh Netting

These are the workhorses of the temporary containment industry, forming the basis of many recreational and light industrial nets.

- Characteristics: These nets are made from synthetic fabric fibers, often supplied in knotless construction for uniform strength. They possess high shock absorption capabilities and are strong relative to their weight. They are naturally resistant to rot and mildew and are often treated with UV inhibitors for moderate weather resistance.

- Common Uses: Due to their low cost, flexibility, and ability to absorb energy, they dominate the market for sports nets (like baseball backstops, golf cages, and soccer goals). They are also widely used as temporary safety netting in construction to catch falling debris and as specialized shade cloth in nurseries.

- Limitations: The fibers are not impervious to environmental wear. Prolonged, intense UV exposure will eventually degrade them, making them brittle and reducing load-bearing capacity, requiring replacement every 5 to 10 years. Critically, they are easily cut, chewed, or compromised, making them unreliable for robust animal containment or high-security applications. Furthermore, they will melt and burn in a fire, posing a significant risk in industrial settings.

2.2. Polyethylene (PE) & Polypropylene (PP) Netting

This category encompasses the most lightweight, readily available, and affordable types of mesh netting, typically found in consumer goods.

- Characteristics: PE and PP are chemically inert polymers, meaning they are inherently rot-proof. They are manufactured either by extrusion or simple weaving and are characterized by their light weight and low cost. They are often dyed green or black and sold in large rolls.

- Common Uses: Their primary use is in temporary, low-impact scenarios: general garden netting (keeping birds and squirrels off fruit), light-duty bird netting (over home eaves or simple pond netting), and basic fencing in agricultural fields. Their affordability makes them ideal for seasonal or single-use applications where replacement is expected.

- Limitations: These materials are inherently low-strength. They are prone to stretching, knot slippage, and tearing, especially under tension or dynamic load. PE in particular is highly susceptible to embrittlement after just a few seasons of sun exposure, drastically reducing its usefulness. They are easily compromised by strong winds, hail, or any persistent animal contact, disqualifying them from being considered heavy duty netting.

2.3. Ultra-Fine Mesh Netting

This category is defined by function rather than material, focusing entirely on mesh size.

- Characteristics: Ultra-fine nets have an extremely tight mesh size—often ranging from 0.1 mm to 1.5 mm. The material can be nylon, PE, or fine metal wire. This minuscule aperture is designed to create a physical barrier against very small pests or particles.

- Common Uses: Specialized garden insect netting (e.g., protecting delicate crops from pests like cabbage moth, flea beetle, or carrot fly), plant covers in specialized greenhouses, filter media in aquaculture, and scientific sieving or particle separation.

- Limitations: This netting is exceptionally delicate and has very low strength. It is easily snagged, torn, or punctured by even small pieces of debris or simple garden tools. The fine weave can also reduce the breathability of the enclosed area compared to large-aperture cable netting, which can be an issue in hot, humid climates. It is never suitable for physical impact, structural support, or permanent containment.

2.4. Knotted vs. Knotless Netting

The way a net is fabricated, whether polymer or fiber rope, dictates its final performance characteristics.

- Knotted Netting: This traditional method involves physically tying the ropes or strands at each intersection (the node). While historically strong, the knot itself is a point of stress concentration. It is bulkier, prone to abrasion and high friction wear, and a common point of failure when subjected to high tension.

- Knotless Netting: These nets are typically braided, woven, or thermally fused, where the crossing strands are interlocked without a physical knot. This method generally offers better uniform strength, less bulk, and better longevity as there are no sharp edges or friction points. Knotless nets are widely used in commercial fishing and lighter-duty aviary netting.

- Superiority in Metal: When it comes to true heavy duty netting for structural or containment roles, the strongest approach is found in the metallic construction of stainless steel mesh. Instead of relying on vulnerable knots, the Hebmetalmesh system uses high-strength, corrosion-resistant ferrules to mechanically interlock the cables. This effectively eliminates all common weak points associated with knots, ensuring that the net’s structural integrity is maintained across its entire surface. The high-tensile metal mesh vastly exceeds the load-bearing capacity of even the strongest polymer knotless netting.

Chapter 3: The Premium Solution: Handwoven Stainless Steel Cable Netting

Projects demanding security, permanence, sophisticated design, and guaranteed safety require a material that transcends the limitations of plastic and nylon. This is where Hebmetalmesh handwoven stainless steel cable netting comes into its own—it is not merely netting; it’s a high-tensile, flexible architectural and security barrier designed for a lifetime of performance.

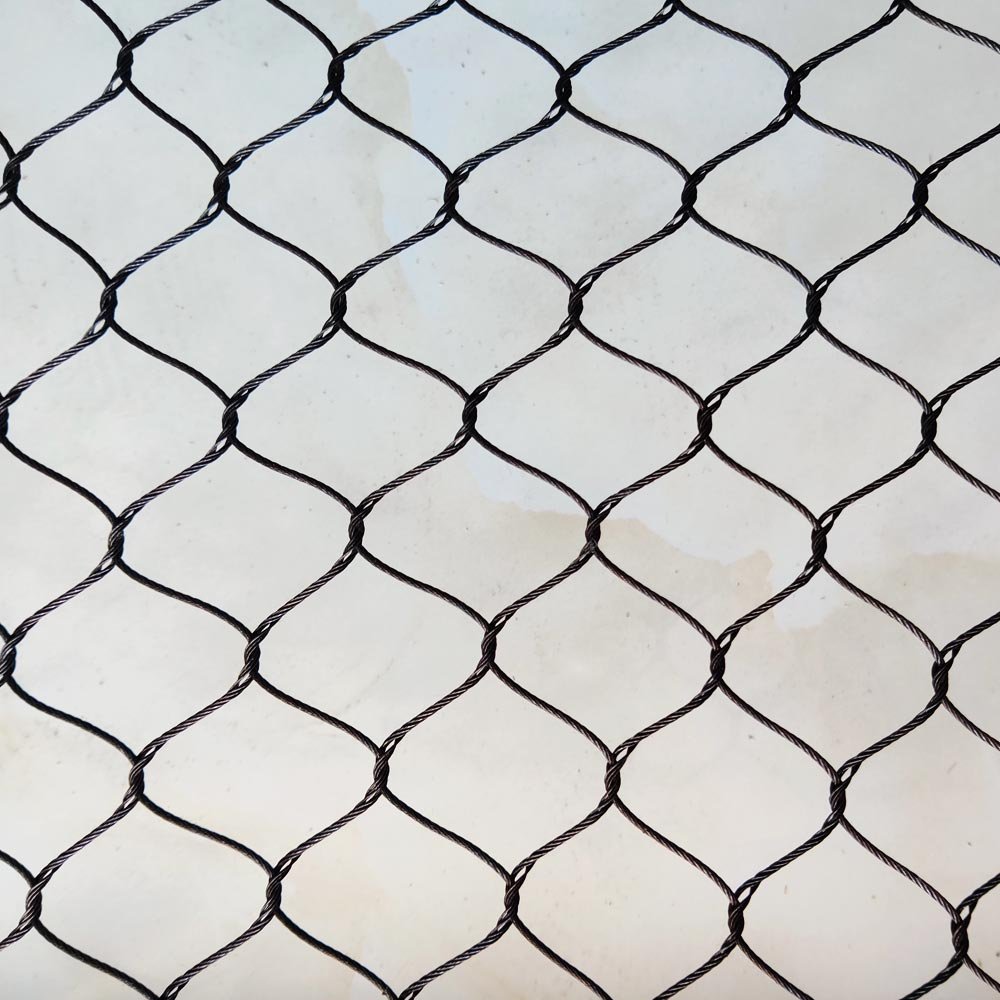

What is Handwoven Stainless Steel Cable Netting?

Our wire mesh netting is a unique, three-dimensional structure created by interweaving high-grade stainless steel cables to form a consistent diamond (or rhombus) pattern. Unlike brittle welded wire mesh or low-strength polymer nets, this cable mesh is characterized by its exceptional flexibility, extremely high load capacity, and maximum corrosion resistance. The diamond weave is critical; when tensioned on a perimeter frame, it distributes impact energy across multiple cables and anchor points simultaneously, giving it an unparalleled ability to absorb significant dynamic impact and maintain structural integrity. This is the ultimate solution for demanding safety netting in high-stakes environments.

The Hebmetalmesh Advantage: Material Superiority

At the core of our product is the material itself: SS304/316 Stainless Steel. We exclusively use these premium alloys for our cables and ferrules. This is a deliberate choice because it ensures two key benefits that no polymer net can match:

- Superior Corrosion Resistance: SS304 offers excellent resistance to general corrosion, making it perfect for most inland outdoor and indoor applications. However, for projects near the coast, swimming pools, or in heavily polluted industrial areas, we recommend SS316. This alloy contains molybdenum, which dramatically enhances resistance to chlorides and salts, guaranteeing exceptional longevity and eliminating the risk of pitting corrosion or rust staining that lesser grades exhibit.

- Unmatched Longevity and Safety: When we talk about heavy duty netting, we mean a solution that lasts. Our stainless steel mesh nets are engineered to withstand extreme temperatures (they are non-flammable), harsh chemicals, heavy dynamic loads, and intense UV exposure—factors that cause competing nets to fail rapidly. This netting is a true permanent installation, designed for a 20+ year lifespan with minimal maintenance.

The Handwoven Process: Strength in Design

The true difference between a mass-produced product and a high-performance Hebmetalmesh net is the handwoven process. Our technique involves precisely interlocking the high-tensile cables at each junction using heavy-duty, corrosion-resistant ferrules. The result is a net with no sharp edges, maximum flexibility, and—most importantly—no weak points.

The ferrules, instead of being points of stress like a knot, act as incredibly strong, load-transferring connectors, creating a homogeneous, uniform strength across the entire mesh surface. This construction is what enables its use as reliable construction netting and indispensable structural safety netting. The handwoven method ensures that the net retains its form and integrity even when placed under massive tension, allowing for its application in three-dimensional zoo habitats and complex architectural infill.

Customization and Aesthetics: Beyond Function

We understand that permanent wire mesh netting must be functional, but it must also integrate seamlessly with the architectural vision. Hebmetalmesh specializes in customization to meet the most exacting design specifications:

- Custom Roll Sizes: We manufacture nets precisely to fit any perimeter or frame dimension, eliminating the need for difficult, wasteful on-site fabrication.

- Cable Diameters & Mesh Openings: We offer a wide range of specifications, from 1.2mm cables with a small mesh size (ideal for small aviary netting) up to 3.2mm cables with large openings (perfect for architectural infill or large containment).

- Aesthetic Options: For projects where visual discretion is paramount, such as museum barriers or residential railings, we offer a black oxide finish. This premium treatment chemically blackens the stainless steel, making the net virtually invisible from a distance, allowing it to blend perfectly with decorative facades and modern interiors.

Direct Comparison Table: Stainless Steel vs. Common Netting Types

The value proposition of stainless steel mesh becomes undeniable when directly compared against the polymer materials it replaces. While the initial cost of our solution is higher, the long-term return on investment is unparalleled.

| Feature | Polyethylene Netting | Polyester Netting | Hebmetalmesh Stainless Steel |

|---|---|---|---|

| Lifespan | 1-3 years | 5-10 years | 20+ years (Permanent) |

| Strength | Low (Tears Easily) | Medium (Good for Shock) | Extremely High (High-Tensile Cable) |

| UV Resistance | Poor to Fair (Becomes Brittle) | Good (Requires treatment) | Excellent (No Degradation) |

| Corrosion Resistance | N/A (Chemically Inert) | N/A (Rot-Resistant) | Excellent (SS304/SS316) |

| Animal Resistance | Low (Easily Chewed/Broken) | Medium (Requires Thick Gauge) | Maximum (Animal-proof Containment) |

| Fire Resistance | Melts, Highly Flammable | Melts, Highly Flammable | Non-flammable |

| Cost | Low (High Replacement Cost) | Medium (Moderate TCO) | High (Lowest Long-term Investment) |

Chapter 4: Innovative Applications of Stainless Steel Mesh Netting (Beyond the Zoo)

While stainless steel cable netting is universally recognized as the gold standard for zoo enclosures and specialized aviary netting, its unique combination of strength, flexibility, and aesthetic appeal has allowed it to redefine boundaries across multiple industries. It has replaced rigid metal, fragile glass, and bulky polymers in markets traditionally served by inferior materials.

Architectural & Design Marvels

The inherent flexibility and high tensile strength of our netting allow architects and designers to create safe, yet transparent, barriers that enhance their environments.

- Balcony Safety & Fall Protection: Stainless steel netting provides a near-invisible protective barrier for high-end residential balconies and commercial terraces. It is an elegant alternative to bulky glass or metal railings, providing code-compliant safety netting without obstructing light or panoramic views.

- Staircase Railing Infill: In modern commercial and residential spaces, the mesh replaces traditional balusters to create a transparent, open, and fluid look. It is often used as a kinetic or dynamic element that contrasts beautifully with timber, steel, or concrete frames, meeting safety standards while maintaining an open-plan aesthetic.

- Decorative Facades and Sunscreens: Applied as a second-skin facade, the netting can function as a dynamic sunscreen, significantly reducing heat gain on the building’s exterior while adding texture and dimension. The mesh’s natural reflectivity or the sophisticated black oxide finish offers compelling design possibilities.

- Interior Design Partitions: The light, breathable quality of the mesh makes it perfect for dividing large, open-plan spaces in offices, galleries, or retail environments. It creates visual separation without blocking light or airflow, offering a modern, industrial alternative to glass walls.

Industrial & Safety Powerhouse

For industrial applications, the strength-to-weight ratio of stainless steel mesh is critical for heavy-duty netting roles where failure could lead to significant damage or injury.

- Heavy-Duty Debris Netting for Construction: On large skyscraper and bridge projects, the netting is used as a robust construction netting floor or perimeter barrier below active work areas. Unlike standard plastic mesh, it has the tensile strength to reliably catch heavy tools, metal components, and large pieces of concrete debris, ensuring the safety of workers and the public below.

- Machine Guarding and Safety Barriers: In automated factories and processing plants, the mesh is used to create customized safety cages around hazardous or robotic machinery. Its transparency allows operators to monitor the equipment closely, while the impenetrable structure ensures full compliance with critical industrial safety regulations.

- Load Securing and Cargo Division: The flexible, yet incredibly strong, nature of the mesh makes it excellent for securing specialized or irregularly shaped loads during transport, offering a durable solution far superior to simple polymer cargo nets or tie-down straps.

High-Security Applications

When security, deterrence, and high-tensile resistance are the primary goals, SS mesh provides a robust, anti-climb, and durable solution.

- Perimeter Fencing for Sensitive Areas: Used in power stations, data centers, and military bases, the netting offers a high-security barrier. When tensioned correctly, its inherent flexibility makes it extremely difficult to gain a foothold for climbing, and its dense cable construction is highly resistant to common cutting tools.

- Aviary Netting for Large-Scale Enclosures: For zoos or large commercial breeding facilities that require robust containment for powerful or intelligent animals (e.g., primates, large birds of prey), our aviary netting provides a structure that is both escape-proof and long-lasting, minimizing the visual intrusion for guests.

- Agricultural & Aquaculture Trellising: In agriculture, particularly for high-value or long-term vine crops like grapes and hops, the stainless steel mesh acts as a permanent, ultra-strong trellising system. Unlike twine or wood, it never needs replacing, can support enormous crop loads year after year, and won’t rot or harbor disease.

Chapter 5: How to Choose the Right Mesh Netting – A Practical Checklist

Selecting the correct mesh netting requires a structured evaluation of your project’s specific needs. To ensure you choose a solution that delivers maximum performance, safety, and long-term value, ask yourself the following critical questions:

1. What is my primary goal? (Containment, Protection, Safety, Decoration?)

- Temporary Exclusion/Light Barrier: If you only need to keep leaves out of a pond or a few birds off seasonal crops, simple PE garden netting is likely sufficient.

- Containment, Safety, or Architectural Infill: If the net must reliably prevent a human fall, secure a heavy industrial load, contain a high-value or dangerous animal, or serve as a permanent facade, you absolutely require heavy duty netting like stainless steel mesh.

2. What are the environmental factors? (Sun, salt, wind, impact?)

- High UV Exposure: Polymer nets will degrade rapidly unless heavily treated and maintained. Stainless steel is completely unaffected by sunlight and requires no treatment.

- Salt/Chloride Environment: If the net is near the coast or an indoor pool, you must specify SS316 stainless steel for maximum corrosion resistance against salt and chlorides.

- Wind/Impact Load: Areas prone to heavy wind, hail, or potential human/animal impact require the high tensile strength and energy distribution of a woven metal cable net to prevent tear-out or structural failure.

3. What is the required strength? (Will it hold a person, an animal, or just leaves?)

- This is not a metric to guess. Will the net hold just a few ounces (e.g., fine insect mesh) or a dynamic load of thousands of pounds (e.g., a construction netting safety floor or a primate enclosure)? Your answer dictates the minimum cable diameter and material required. Never compromise on strength when safety is a factor.

4. What is the desired lifespan? (Temporary seasonal use or a permanent installation?)

- If the project is a permanent structure (a zoo exhibit, a building facade, a highway safety barrier), the recurring cost of replacing polymer nets will quickly exceed the initial investment in permanent wire mesh netting like stainless steel. Always choose the highest possible longevity for permanent infrastructure.

5. What is my budget? (Considering initial cost vs. long-term value and replacement costs.)

- Do not focus only on the initial purchase price. Calculate the Total Cost of Ownership (TCO). A temporary polymer net replaced five times over 20 years costs five times the material plus five times the installation labor. A stainless steel net is an investment that requires one installation and zero material replacement costs over the same period, making it the smarter financial choice for long-term projects.

Conclusion: Investing in Long-Term Performance

The selection of the right mesh netting is defined entirely by its intended, and critical, application. For temporary, low-impact needs—like light seasonal garden netting or basic sports barriers—affordable plastic or nylon netting may suffice. They serve a necessary, though limited, purpose.

However, for any project where safety, security, and longevity are non-negotiable—whether it’s high-altitude construction netting, a permanent aviary netting enclosure, or an elegant, permanent architectural facade—the investment in handwoven stainless steel cable netting from Hebmetalmesh is the only true solution. You gain the peace of mind knowing you have the ultimate heavy duty netting available, backed by the longevity of SS304/316 materials. It’s an investment that pays for itself over a lifetime of zero replacements. Contact our experts today for a free consultation and custom quote for your project. We’re here to help you secure a permanent solution.