Introduction to Stainless Steel Enclosures

Stainless steel enclosures serve a crucial role across various industries, particularly in applications involving the housing and protection of animals, such as in zoos and aviaries. The importance of these structures lies not only in their aesthetic appeal but also in their ability to provide safety and durability, which are paramount when designing habitats for living creatures. Stainless steel, known for its strength, weather resistance, and longevity, is an optimal material for constructing enclosures that withstand the test of time.

One of the significant advantages of using stainless steel for enclosures is its inherent resistance to corrosion. This property is essential when considering environments that may expose the materials to moisture, chemicals, or varying weather conditions. Stainless steel enclosures do not require extensive maintenance, making them a cost-effective solution over time. Their robust nature allows these structures to endure the stresses of everyday use, which is particularly important in animal facilities where interactions can be vigorous and frequent.

Furthermore, stainless steel enclosures help ensure the safety of both animals and visitors. With their high tensile strength and resistance to damage, these enclosures provide a secure environment that minimizes the risk of escapes or injuries, allowing for a tranquil experience for visitors while prioritizing the well-being of the animals. The design of these enclosures can also be adapted to various sizes and layouts, meeting the specific needs of different species and habitats effectively.

In essence, stainless steel enclosures represent a perfect blend of quality and durability, offering a reliable solution for creating safe, appealing, and long-lasting spaces for animals in a variety of settings. Their significance in environmental stability and animal welfare cannot be overstated, laying a strong foundation for future advancements in habitat design.

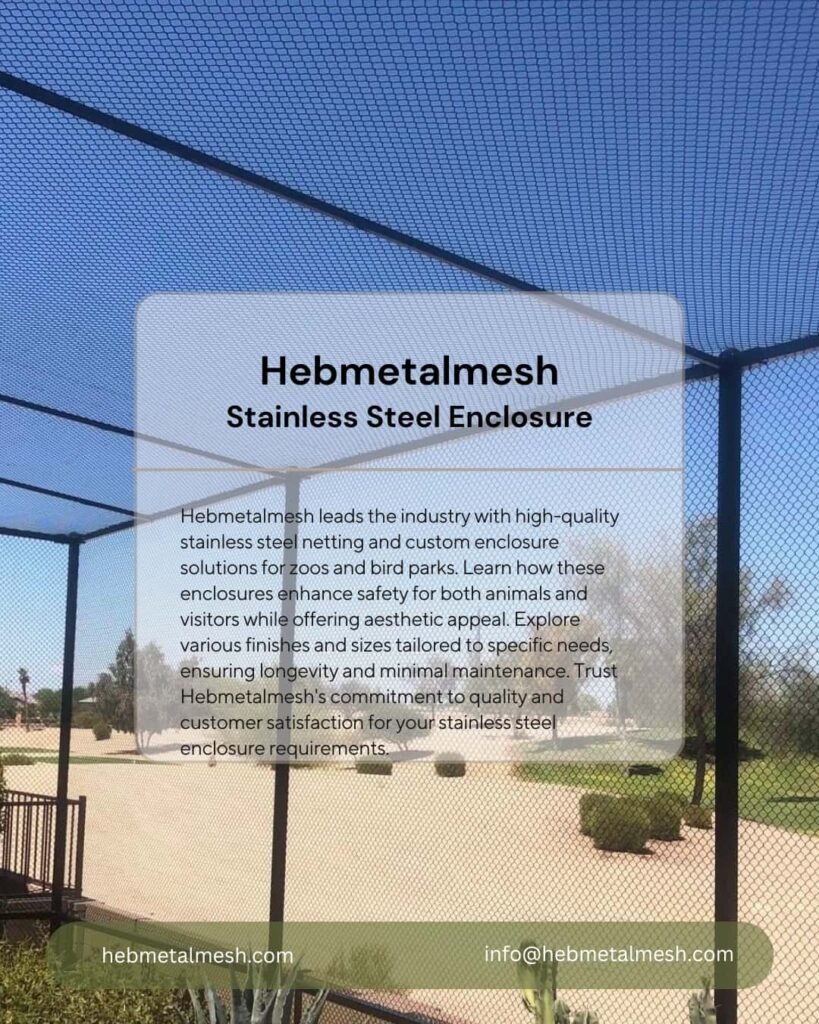

Hebmetalmesh: A Leader in Stainless Steel Netting

Hebmetalmesh has established itself as a distinguished name in the industry of stainless steel enclosures, particularly known for its commitment to creating high-quality, handwoven stainless steel netting. Founded over two decades ago, the company has built a solid reputation as a professional manufacturer, continuously evolving to meet the demands of a diverse clientele. Its origins trace back to a small workshop focused on crafting reliable steel netting solutions, which has since blossomed into a full-scale production facility equipped with advanced technology and skilled artisans.

With years of experience under its belt, Hebmetalmesh has honed its methods and practices, ensuring that each product delivered meets stringent quality standards. The company specializes in flexible handwoven stainless steel netting, which serves various applications, including safety barriers, architectural designs, and industrial uses. By prioritizing quality in every aspect of production, from raw materials to the final inspection stages, Hebmetalmesh ensures that their stainless steel enclosures provide durability, strength, and resistance to corrosion.

Furthermore, Hebmetalmesh’s dedication to customer satisfaction sets it apart from competitors. The company prides itself on understanding the unique needs of its clients, offering tailored solutions and unmatched support throughout the purchasing process. This commitment has fostered long-lasting relationships with customers around the globe, who rely on Hebmetalmesh’s products not only for their robustness but also for their aesthetic appeal.

Through continuous innovation and a focus on quality, Hebmetalmesh remains at the forefront of the stainless steel netting industry. The company’s unwavering dedication to excellence ensures that it is well-positioned to remain a leader in the realm of stainless steel enclosures for many years to come.

Product Offerings: Fence Panels and Rolls

Hebmetalmesh prides itself on a wide array of offerings that cater to varying needs in the realm of stainless steel enclosures. One of the standout products in their lineup is the handwoven stainless steel netting, which is specifically designed for applications ranging from industrial fencing to residential use. This unique handwoven construction not only ensures durability but also provides a level of security that is paramount in enclosures where safeguarding is essential.

The stainless steel fence panels are available in several sizes, allowing for customized applications that can fit any project requirement. One popular option is the 30′ x 60′ rolls, offering both convenience and versatility. For those who require specific dimensions, Hebmetalmesh also offers custom-size solutions tailored to meet individual client specifications. This adaptability in sizing helps in catering to a variety of scenarios, whether it is securing a large industrial site or providing a protective barrier around a smaller area.

In addition to their standard offerings, Hebmetalmesh also emphasizes the importance of quality in its manufacturing processes. Each stainless steel enclosure is crafted to withstand the elements, ensuring long-lasting performance in diverse environments. Their commitment to excellence extends beyond mere functionality; the aesthetic appeal of these enclosures is also a consideration. Customers can select from various finishes and designs to ensure that their fencing not only serves its purpose but also complements the surrounding space.

By choosing Hebmetalmesh for stainless steel enclosures, clients can rest assured that they are investing in products that will deliver quality, durability, and versatility. With a robust range of fence panels and rolls, the company positions itself as a leader in providing effective solutions for any enclosure need.

Material Quality: Stainless Steel 304/316

When considering the construction of durable and high-quality enclosures, the choice of material is paramount. Hebmetalmesh primarily utilizes two types of stainless steel: 304 and 316, which are renowned for their exceptional properties that cater to various environmental conditions and applications. Both variants are widely recognized for their corrosion resistance and strength, making them ideal for use in settings where durability is essential.

Stainless steel 304 is the most versatile and commonly used grade, offering excellent resistance to corrosion and oxidation. This quality makes it suitable for enclosures exposed to moisture, such as those used for housing animals outdoors. Its robustness ensures that it can withstand physical stress, making it a reliable choice for various applications, including food processing and chemical handling. Furthermore, stainless steel 304’s non-reactive nature contributes to maintaining a clean and safe environment for animals.

On the other hand, stainless steel 316 provides an elevated level of protection against harsh conditions. This variant contains molybdenum, which enhances its resistance to pitting and crevice corrosion, particularly in chloride environments, such as coastal areas where saltwater exposure is a concern. This makes the stainless steel enclosure constructed from 316 exceptionally durable when faced with the elements. Its strength and resistance to wear and tear further ensure that even after prolonged outdoor use, the integrity of the enclosure remains intact, thereby safeguarding the inhabiting animals.

Hebmetalmesh’s commitment to using high-quality stainless steel 304 and 316 ensures that all enclosures deliver remarkable longevity and performance. In a world where durability and safety are paramount, these materials stand out as the ideal choice for creating reliable solutions in animal confinement and beyond.

Color Options: Nature and Black Oxide Finishes

When considering the aesthetic appeal and functional performance of stainless steel enclosures, the choice of finish plays a significant role. Hebmetalmesh provides an array of color options, specifically focusing on the natural stainless steel finish and the black oxide finish. Each offering not only enhances visual attractiveness but also serves distinct practical advantages.

The natural stainless steel finish is characterized by its shiny, metallic look, which exudes a modern, sleek aesthetic. This finish is particularly beneficial for environments where cleanliness and hygiene are paramount, such as in restaurants or laboratories, as it is resistant to staining and easy to maintain. Its reflective surface also has the added benefit of blending seamlessly with various architectural styles, thus ensuring that the enclosure complements the surrounding space rather than detracts from it. The durability of this finish makes stainless steel enclosures ideal for both indoor and outdoor applications, sustaining their appearance against varied environmental conditions.

Conversely, the black oxide finish provides a unique depth and elegance to stainless steel enclosures. This finish not only enhances visual appeal but also offers additional protection against corrosion and wear. The matte black appearance can create a bold, sophisticated look, making it a favorite for modern designs. This finish is particularly advantageous in industrial settings where equipment can be exposed to harsher conditions, as it minimizes glare and enhances visibility. Furthermore, black oxide finishes can help reduce the accumulation of dirt and grime, further maintaining the enclosure’s integrity over time.

In conclusion, both the natural stainless steel finish and the black oxide finish from Hebmetalmesh provide practical and aesthetic benefits, ensuring that the stainless steel enclosures are not only functional but also visually appealing. These options allow for tailored solutions that meet the specific needs of various environments while maintaining the high-quality standards expected from durable stainless steel products.

Applications in Zoos and Bird Parks

Stainless steel enclosures play an essential role in the habitat design of zoos and bird parks, offering both durability and aesthetic appeal. Hebmetalmesh has successfully supplied products for over 100 zoos and bird parks worldwide, meeting the unique demands of these environments with specialized installations that enhance animal welfare and visitor enjoyment.

In zoos, stainless steel enclosures are critical for ensuring the safety and security of both the animals and the public. The robustness of stainless steel allows for the construction of enclosures that can withstand the wear and tear of diverse weather conditions, animal interactions, and general usage. For example, Hebmetalmesh designed a series of stainless steel mesh enclosures for a renowned zoological facility that houses large carnivores. These enclosures not only provide a secure habitat but also allow for visibility and engagement for visiting guests, promoting education and awareness regarding these magnificent animals.

Bird parks, similarly, benefit significantly from the use of stainless steel enclosures. The open designs that often characterize these attractions require materials that are both strong and resistant to corrosion. Stainless steel mesh provides an ideal solution, facilitating a safe yet expansive environment where birds can fly freely. In a recent project, Hebmetalmesh implemented a large-scale aviary constructed from stainless steel materials. This allowed for a beautiful display of exotic birds while ensuring their safety from potential threats.

Furthermore, the versatility of stainless steel enables customization to meet the specific needs of various species, ensuring that their welfare is prioritized. With Hebmetalmesh’s extensive experience in delivering such enclosures, zoos and bird parks have access to innovative solutions that enhance the habitats of their inhabitants. In conclusion, the application of stainless steel enclosures is pivotal in the functioning of zoos and bird parks, providing a combination of safety, durability, and design flexibility.

Customer Trust and Market Credibility

Hebmetalmesh has established itself as a reputable name in the industry, particularly when it comes to stainless steel enclosures. This credibility is built on years of delivering high-quality products that meet the diverse needs of clients across various sectors. The company’s long-standing history in manufacturing exceptional stainless steel solutions showcases its commitment to quality and performance, instilling trust among customers.

Customer reviews play a pivotal role in illustrating the reliability and effectiveness of Hebmetalmesh’s products. Positive testimonials frequently highlight not only the durability of their stainless steel enclosures but also the exceptional customer service provided. Clients appreciate how the company prioritizes their needs and works collaboratively to develop solutions that are tailored to specific applications, which further solidifies its standing in the marketplace.

The technical expertise and advanced manufacturing processes employed by Hebmetalmesh underscore its dedication to producing stainless steel enclosures that are robust and dependable. The use of high-grade materials ensures that the products can withstand harsh environmental conditions, thereby meeting the demands of industries such as telecommunications, transportation, and energy. This level of quality assurance contributes significantly to the overall trust customers place in the brand.

Moreover, with a growing base of satisfied customers and repeat business, Hebmetalmesh’s reputation continues to flourish. In today’s competitive market, the integration of innovation and high standards of quality within their stainless steel products has set a benchmark for competitors, making Hebmetalmesh a trusted partner for businesses looking to invest in reliable, long-lasting solutions. The company’s focus on integrity not only enhances its market credibility but also solidifies its status as a leader in the field of stainless steel enclosures.

Competitive Advantages of Using Stainless Steel Enclosures

Stainless steel enclosures present a myriad of competitive advantages that distinguish them from alternatives like wood, plastic, or aluminum. One of the most significant attributes is their exceptional durability. Stainless steel is inherently resistant to corrosion, rust, and various environmental factors, which ensures a longer lifespan compared to other materials. These enclosures can withstand harsh weather conditions, making them ideal for outdoor applications and environments that challenge other materials. As such, stainless steel enclosures from Hebmetalmesh provide a reliable solution for those seeking long-term investments.

In addition to their durability, stainless steel enclosures require minimal maintenance. Unlike wooden structures that may need regular painting or sealing, or aluminum constructions susceptible to denting and discoloration, stainless steel surfaces can be cleaned easily and require infrequent care. This low maintenance requirement not only simplifies upkeep but also reduces costs over time, adding to the overall value proposition of choosing stainless steel enclosures.

Safety is another key factor where stainless steel enclosures excel. The robust nature of stainless steel helps prevent tampering or damage, ensuring that both animals and visitors remain secure, especially in settings such as zoos or botanical gardens. By using stainless steel enclosures, facility operators can enhance safety protocols, thus instilling additional confidence among visitors regarding the welfare of the animals and the integrity of the environment.

Finally, the aesthetic appeal of stainless steel cannot be overlooked. Its modern, sleek appearance can complement various architectural designs while providing a professional look for commercial or institutional applications. The ability of stainless steel enclosures to blend functionality with visual appeal makes them a preferred choice for many organizations, evident in the rising trend toward their use in public spaces and private facilities alike.

Conclusion: Why Choose Hebmetalmesh for Your Enclosure Needs

When it comes to selecting the perfect enclosure for various applications, the advantages offered by stainless steel enclosures become increasingly paramount. Hebmetalmesh stands out as a leading provider in this field, offering products that exemplify quality and durability. Our stainless steel enclosures are crafted with meticulous attention to detail, ensuring that they meet both industry standards and customer expectations.

Quality materials are the cornerstone of our manufacturing process. We utilize high-grade stainless steel, which not only enhances the aesthetic appeal of the enclosures but also provides superior resistance to corrosion, rust, and environmental factors. As a result, our enclosures are particularly well-suited for both indoor and outdoor applications, where durability is essential. By choosing Hebmetalmesh, clients can have confidence that their enclosures will maintain their integrity over time, thereby reducing the need for frequent replacements and repairs.

Another significant aspect of Hebmetalmesh’s reputation is our unwavering commitment to reliability. Our stainless steel enclosures are rigorously tested to ensure they perform effectively under various conditions. This rigorous approach not only enhances the longevity of our products but also instills trust among our customers. In addition, we pride ourselves on providing exceptional customer service, understanding that each project may have unique requirements. Our team is dedicated to guiding clients through the selection process, ensuring they find the ideal stainless steel enclosure to meet their specific needs.

In summary, by choosing Hebmetalmesh, clients benefit from high-quality materials, reliable performance, and excellent customer service, making us the preferred choice for stainless steel enclosure solutions. Our commitment to excellence ensures that every project we undertake is a testament to our expertise and dedication to customer satisfaction.

FAQ: Stainless Steel Enclosure

A1: Handwoven mesh offers superior flexibility and impact resistance. This creates an exceptionally durable and dynamic stainless steel enclosure that safely absorbs force, ideal for active animals.

A2: Yes, we specialize in custom stainless steel enclosure panels tailored to your exact design. Our handwoven technique allows for versatile shapes and sizes to fit any complex zoo or aviary habitat.

A3: The handwoven construction has no rigid welds to fail, creating a safe and reliable stainless steel animal enclosure that prevents injuries from sharp edges, even under significant force.

A4: Absolutely. Our heavy-duty stainless steel enclosure netting is designed with high-tensile strength cables, providing secure and dependable containment for the most powerful animals, including large cats and bears.

A5: The black oxide stainless steel enclosure mesh provides a low-glare, natural aesthetic that blends into the environment, reducing visual impact for a more authentic and stimulating habitat for the animals.