In the world of wildlife conservation, agricultural protection, and high-end architectural design, the term cage netting has evolved far beyond simple chicken wire. Today, it represents a sophisticated intersection of material science and animal welfare. For professionals managing zoo enclosures, massive aviaries, or protective garden perimeters, the choice of netting is the difference between a temporary fix and a 30-year infrastructure investment.

As the owner of Hebmetalmesh, a specialized factory producing handwoven stainless steel netting, I have seen firsthand how the right mesh selection transforms environments. This guide provides an exhaustive look at the cage netting industry, from procurement secrets to technical specifications, ensuring you have the data needed to make an informed decision for your facility or farm.

What is the Best Cage Netting?

The best cage netting for long-term use is handwoven stainless steel rope mesh. Unlike plastic or galvanized wire, it offers 30+ years of durability, is UV-resistant, and maintains high transparency. For professional zoo and aviary applications, 304 or 316-grade stainless steel with a black oxide finish is the industry standard for security and aesthetics.

I. Where to Buy Heavy-Duty Cage Netting for Wildlife Enclosures

When searching for heavy-duty cage netting, the “where” is just as important as the “what.” Most consumers and even some contractors mistakenly turn to local hardware depots or general online retailers. However, wildlife containment requires industrial-grade specifications that retail stores simply do not stock.

1. The Benefit of Buying Factory-Direct

At Hebmetalmesh, we operate as a direct-to-consumer factory. Buying direct from the source offers three distinct advantages:

- Cost Efficiency: Buying direct eliminates the “middleman markup”—the 30-50% price increase added by distributors.

- Total Customization: While retailers sell fixed sizes (e.g., 10′ x 10′), we manufacture customized rolls and panels up to 30′ x 60′ (9m x 18m). We do not charge additional fees for custom sizes because our weaving process is tailored to the order from the start.

- Quality Control: Every square inch of our handwoven mesh is inspected by the same team that crafted it. There is no ambiguity about the source of the steel or the integrity of the knots.

Pro Tip: Always look for suppliers who offer custom roll sizes at no additional cost. This reduces on-site waste, minimizes seams (which are potential failure points), and significantly lowers installation labor.

2. Material Science: 304 vs. 316 Stainless Steel

Not all “steel” is created equal. When purchasing cage netting for wildlife, you must understand the environment where it will be installed:

- Grade 304: This is the standard for most inland applications. It offers excellent strength and corrosion resistance at a lower price point. It is suitable for most zoos, farms, and garden applications in non-coastal areas.

- Grade 316: Known as the “Marine Grade,” this alloy contains molybdenum, which provides superior resistance to chlorides (like salt) and industrial pollutants. This is essential for zoos or farms located near the coast (within 5 miles of saltwater) or in highly industrial areas where acidic rain is a concern.

3. Verification of Quality and Tensile Strength

Before you buy, ask for material test reports (MTR). High-quality cage netting should have a consistent rope diameter (usually 1.0mm to 3.2mm) and a uniform weave. At Hebmetalmesh, our handwoven process ensures that every knot is physically inspected for integrity. This ensures no “runaway” breaks in the mesh under animal pressure. If a tiger or bear pushes against the mesh, the load is distributed across the entire panel thanks to the interlocked diamond weave.

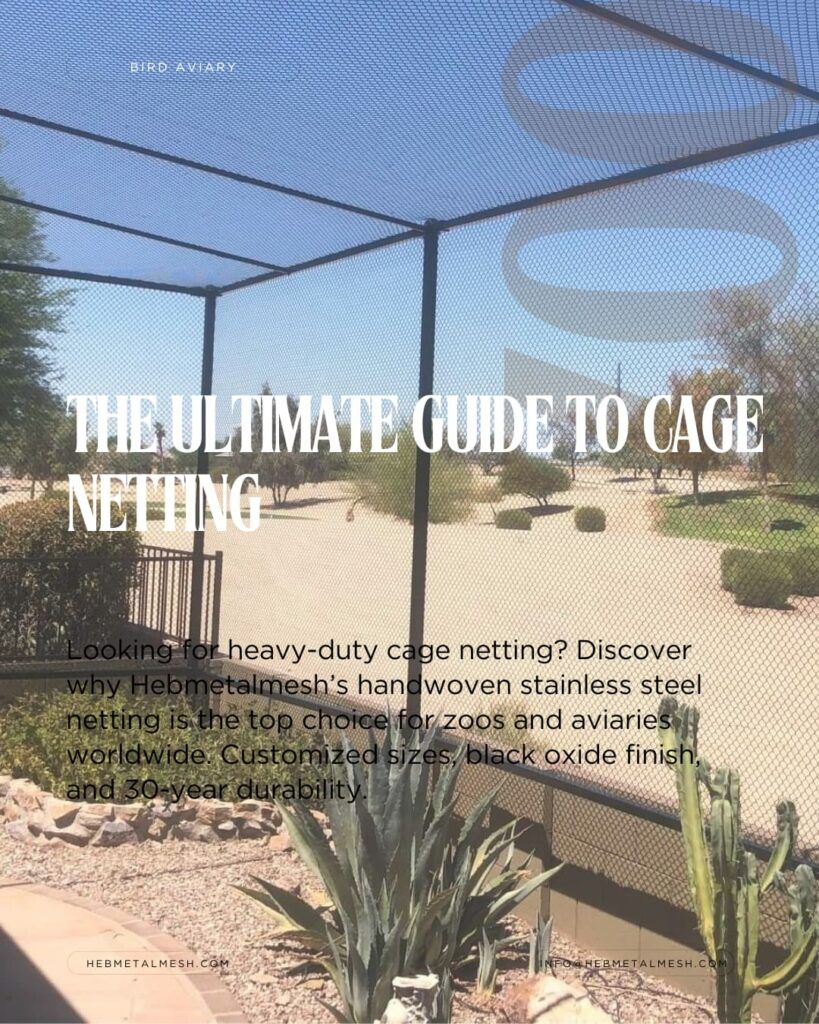

II. Top-Rated Suppliers of Cage Netting for Aviaries in the US

The United States has some of the strictest animal welfare and safety regulations in the world, governed by the USDA and the Association of Zoos and Aquariums (AZA). Consequently, the demand for top-rated aviary netting is high.

Why Hebmetalmesh is a Preferred Supplier for the US Market

While we are a global factory based in Asia, a significant portion of our production is dedicated to US-based zoos, wild parks, and private bird sanctuaries.

- Compliance with Safety Standards: Our mesh meets the physical barrier requirements for containing exotic bird species and protecting them from local North American predators like raccoons, hawks, and foxes.

- Scale and Scope: We can produce panels large enough to cover entire walk-in aviaries without unsightly seams. A single 30′ x 60′ panel can wrap a substantial structure, providing a seamless, “invisible” look that is highly prized by landscape architects.

- Shipping Efficiency: We have optimized our logistics to ensure that custom-woven stainless steel reaches US project sites faster than many domestic distributors can fulfill custom orders. We handle the complexities of international freight to provide a door-to-door experience for our clients.

III. Benefits of UV-Resistant Cage Netting for Garden Protection

For garden enthusiasts and small-scale farmers, “cage netting” usually refers to protection against deer, birds, and smaller pests. Many turn to plastic (nylon or polypropylene) because it is cheap. However, this is often a “false economy.”

1. The Failure of Plastic and Poly-Netting

Plastic netting degrades rapidly under UV radiation. Within 12 to 24 months, it becomes brittle and snaps. This creates a microplastic pollution problem in your soil and leaves your crops vulnerable. Furthermore, plastic netting is easily breached by the teeth of squirrels, rabbits, and groundhogs.

2. The Stainless Steel Advantage

Stainless steel cage netting is naturally UV-resistant. It does not require chemical coatings to survive the sun.

- Aesthetic Integration: Our Black Oxide option is particularly popular for gardens. The matte black finish absorbs light rather than reflecting it, making the netting nearly invisible against green foliage. It allows the beauty of the garden to shine through without the visual clutter of a silver fence.

- Physical Strength: Unlike plastic, squirrels and rodents cannot chew through stainless steel mesh. If you are trying to keep birds out of fruit trees, you need a material that won’t be bypassed by a hungry squirrel.

- Sustainability: A single installation of Hebmetalmesh can outlast 15 cycles of plastic netting. This makes it the most eco-friendly choice for sustainable farming and gardening.

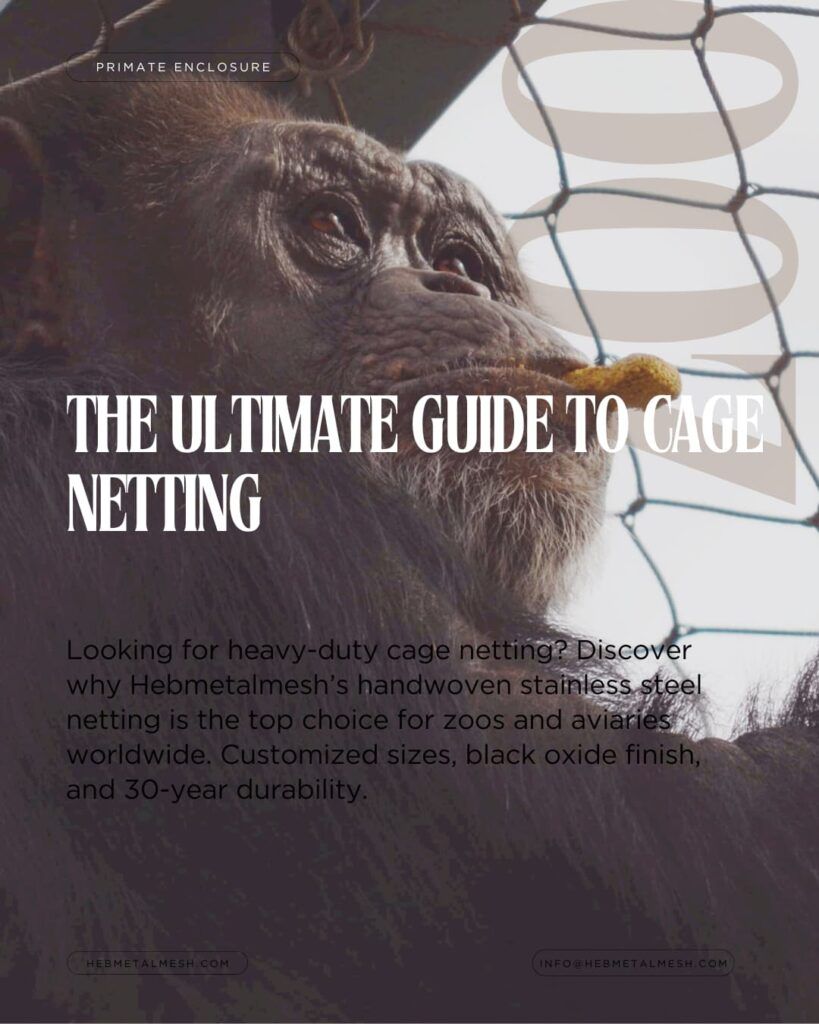

IV. Reviews: Cage Netting for Small Animal Containment

Small animals—primates, squirrels, lemurs, and exotic cats—present unique challenges. They are intelligent, agile, and often have sharp teeth and claws. When reviewing cage netting options, curators focus on three main areas: Safety, Visibility, and Enrichment.

1. Handwoven vs. Welded Wire

Most reviews from zoo curators highlight the danger of “welded” wire. If one weld point fails due to corrosion or stress, the entire structure weakens, and the animal can potentially cut themselves on the sharp broken wire. Handwoven cable mesh uses a “diamond” weave where the ropes are physically knotted or ferruled together. There are no sharp edges, and the flexibility of the mesh acts as a shock absorber. If an animal jumps against it, the mesh “gives” slightly, reducing the risk of impact injury.

2. Flexibility and Behavioral Enrichment

Modern zoo design focuses on “Environmental Enrichment.” Flexible cage netting allows for the creation of “tunnels” and irregular-shaped enclosures that mimic natural habitats. Hebmetalmesh’s stainless steel rope mesh can be draped like fabric, allowing architects to create vertical climbing structures and overhead pathways that move away from rigid, rectangular cages.

3. The “Chew-Proof” Factor

For animals like parrots or primates, the mesh is often a toy as much as it is a barrier. Our 316-grade stainless steel is impervious to the strongest beaks and teeth. Reviews from parrot sanctuaries consistently rank our handwoven mesh as the only material that can withstand the daily “stress tests” provided by large Macaws and Cockatoos.

V. Technical Guide: Best Mesh Size for Cage Netting

Choosing the right “aperture” (the hole size) is the most critical technical decision. If the mesh is too large, the animal escapes or a predator enters. If it’s too small, you lose visibility and increase the weight and cost unnecessarily.

Understanding the Relationship Between Rope Diameter and Aperture

The strength of cage netting is a product of both the rope diameter and the opening size. For smaller birds, a thin 1.2mm rope is sufficient. For a snow leopard or a bear, you would upgrade to a 3.2mm rope with a 3″ or 4″ opening.

Recommended Mesh Sizes Table

| Application | Recommended Mesh Size | Wire Diameter | Recommended Material |

|---|---|---|---|

| Fruit Tree/Bird Protection | 1″ x 1″ (25mm x 25mm) | 1.2mm – 1.5mm | 304 Stainless Steel |

| Small Aviary (Finches/Canaries) | 0.8″ x 0.8″ (20mm x 20mm) | 1.0mm – 1.2mm | 304/316 Stainless Steel |

| Large Aviary (Parrots/Macaws) | 1.5″ x 1.5″ (38mm x 38mm) | 1.6mm – 2.0mm | 316 Stainless Steel |

| Monkey/Primate Enclosure | 2″ x 2″ (51mm x 51mm) | 2.0mm – 2.4mm | 304/316 Stainless Steel |

| Deer/Farm Fencing | 4″ x 4″ (100mm x 100mm) | 2.0mm – 2.5mm | 304 Stainless Steel |

| Big Cats (Tigers/Lions) | 3″ x 3″ (76mm x 76mm) | 3.2mm | 304 Stainless Steel |

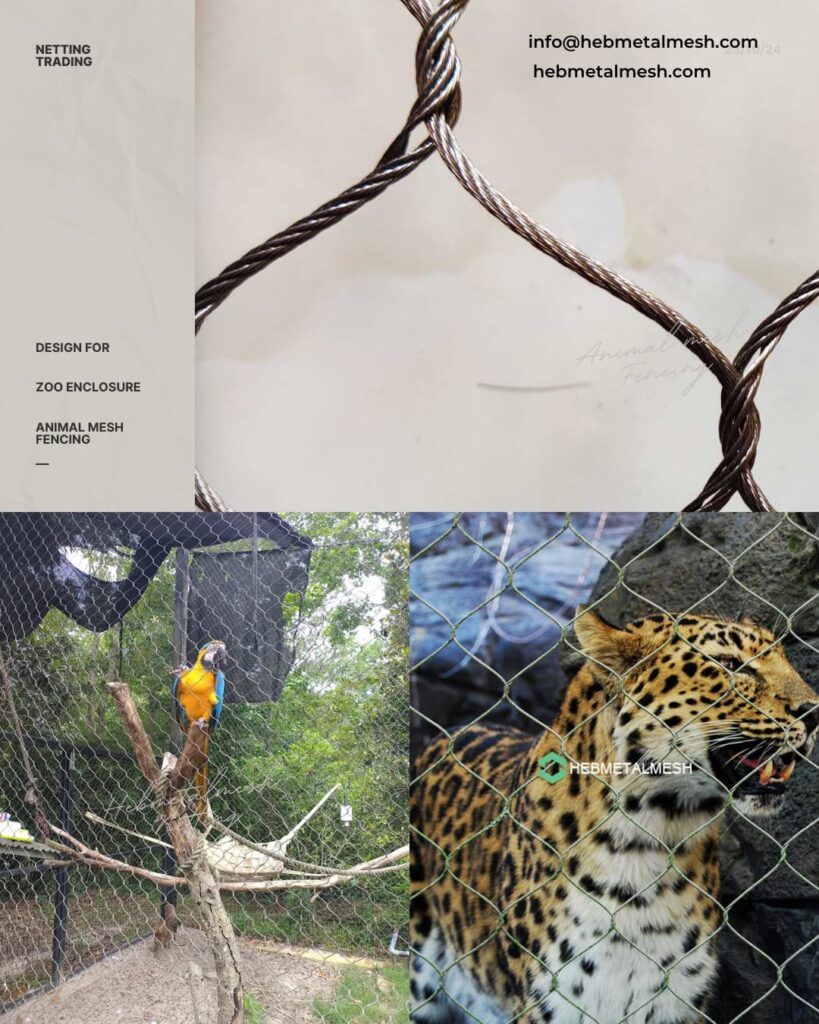

VI. The Black Oxide Option: Why It’s the Industry Standard

At Hebmetalmesh, we offer two primary finishes: Nature (Silver) and Black Oxide.

While the silver “Nature” finish is beautiful for modern architectural railings and staircases, Black Oxide is the gold standard for cage netting in professional zoos and wildlife parks.

- Better Visibility for Visitors: The human eye naturally focuses past dark, matte colors. Black netting “disappears” against a shadowed background or green landscape, allowing visitors to see the animals clearly without the visual “glare” of a shiny metal grid.

- Animal Psychology: Many animals are less stressed by dark mesh. The absence of light reflection creates a more natural, less “caged” feel for the inhabitants.

- Added Durability: The black oxide process is not a paint or a dip; it is a chemical conversion of the steel’s surface. This adds an extra layer of protection against corrosion, which is particularly useful in the high-humidity environments of tropical bird houses or indoor reptile exhibits.

VII. Deep Dive: The Handweaving Process at Hebmetalmesh

What makes our cage netting unique is the human element. Unlike machine-made chain link or welded wire, our stainless steel rope mesh is handwoven by skilled craftsmen.

1. Selecting the Wire Rope

The process begins with selecting high-quality 7×7 or 7×19 construction stainless steel wire rope. A 7×7 rope consists of 7 strands, each made of 7 individual wires. This construction provides the perfect balance of flexibility and breaking strength.

2. The Weaving Loom

Our “looms” aren’t machines, but rather custom-made boards where the mesh is pinned and woven according to the diamond pattern. Each crossing point is secured either by knotting the ropes together (Handwoven Type) or by using high-strength stainless steel ferrules (Ferruled Type).

3. Custom Sizing Without Waste

Because we weave by hand, we can adjust the dimensions of the panel in real-time. If you need a panel that is 12.5 feet wide and 44.2 feet long, we weave exactly that. This “Made to Order” philosophy is why we can offer customized sizes at the same price as standard sizes—there is no waste for us to account for.

VIII. Installation and Maintenance: The “How-To” Authority

One of the biggest questions we receive at our factory is: “Can I install this myself?”

1. The DIY Approach for Small Projects

For garden protection, fruit tree enclosures, or small backyard aviaries, DIY installation is entirely possible. Because our panels are custom-sized, you won’t need to do much cutting, which is the hardest part of working with stainless steel.

Tools Required:

- Stainless Steel Zip Ties or Lacing Wire: To secure the mesh to the frame.

- Tensioned Perimeter Cable: For larger spans where a rigid frame isn’t used.

- Standard Pliers and Cable Cutters: To trim any excess lacing.

2. Tensioning: The Secret to Longevity

Cage netting should be “taught but not stressed.”

- Over-tensioning: Can cause the supporting frame to buckle or put unnecessary strain on the knot points.

- Under-tensioning: Leads to sagging. In high-wind areas, loose mesh will “whip,” causing the metal to fatigue over time. A properly tensioned mesh should feel firm to the touch, similar to a tennis racket.

3. Maintenance Protocols

Stainless steel is virtually maintenance-free, but it is not “invincible.”

- Annual Inspection: Check the perimeter attachments to ensure zip ties or lacing wires haven’t loosened.

- Cleaning: A simple rinse with fresh water once a year is usually all that is required. In coastal areas, this rinse is more important to remove salt spray that can sit on the surface of the metal.

IX. Architectural Trends: The “Invisible” Enclosure

We are seeing a massive shift in zoo architecture toward “Landscape Immersion.” This design philosophy aims to remove the visual barriers between the visitor and the animal.

1. Large-Span Panels

By using our 30′ x 60′ panels, architects can create massive, airy structures that feel like the open sky. By minimizing the number of support poles and seams, the cage netting becomes a secondary element to the landscape.

2. Safety and Public Interaction

Stainless steel rope mesh is soft to the touch compared to jagged chain link. In petting zoos or interactive walk-through aviaries, this is a critical safety feature. Even if a visitor (especially a child) touches or leans against the mesh, there is no risk of cuts or scrapes.

X. Global Logistics: Shipping Cage Netting to Your Door

Buying from a factory like Hebmetalmesh is easy, regardless of where you are located. We have developed a streamlined shipping process that includes:

- Vacuum Packing: To save on shipping costs, the flexible mesh is folded and vacuum-packed into compact wooden crates. This significantly reduces the “volumetric weight” of the shipment.

- Door-to-Door Delivery: We work with international carriers (DHL, FedEx, and sea freight partners) to provide full tracking. For large zoo projects, we handle the customs documentation to ensure a smooth arrival.

- Lead Times: While we are a factory, our handweaving process is efficient. Most custom orders are produced and shipped within 7 to 14 days.

XI. Conclusion: Why Hebmetalmesh is Your Long-Term Partner

When you choose Hebmetalmesh, you aren’t just buying a roll of wire; you are investing in a factory-direct partnership. We understand that every project—whether it’s a backyard fruit tree or a multi-million dollar tiger exhibit—requires precision.

Our Brand Promise:

- Total Customization: We weave to your exact specifications. No extra cost for custom sizes.

- Material Integrity: 100% genuine 304/316 stainless steel with MTR availability.

- Unmatched Scale: We are one of the few factories capable of producing seamless 30′ x 60′ panels.

- Direct Support: You talk directly to the factory owners and experts who understand the weave and the material.

Ready to secure your project with the world’s most durable cage netting?

Visit our Online Store to see our standard options or contact us for a custom quote on your next large-scale wildlife enclosure. We are here to help you build a safer, more beautiful environment for animals and humans alike.

XII. Frequently Asked Questions (FAQ)

A: Galvanized wire typically begins to rust within 3-5 years as the zinc coating wears off. Handwoven stainless steel netting from Hebmetalmesh typically lasts over 30 years, offering a much lower “cost-per-year” over the life of the enclosure.

A: Yes. It is a chemical conversion of the surface of the steel. It will not chip, flake, or peel like paint or plastic coatings.

A: Yes. The diamond weave allows snow to pass through or fall off more easily than solid surfaces. Because of its high tensile strength, it can support significant weight without permanent deformation.

A: Our standard large panels are 30 feet by 60 feet (9m x 18m), but we can customize even larger sizes for specific architectural needs. Contact our technical team to discuss your requirements.

A: Absolutely. We encourage our customers to feel the quality of the handwoven mesh. Contact us via our website to request a sample pack.