Introduction: The Modern Zoo Enclosure – Beyond the Cage

The evolution of zoological architecture is a history of shifting paradigms. We have moved from the 19th-century menagerie—characterized by barred concrete cells and viewing pits—to the 21st-century immersive landscape. Today, the “zoo animal enclosure” is a misnomer; we are building biomes, habitats, and complex ecosystems.

For the modern zoo professional, wildlife park manager, and architect, the stakes have never been higher. The contemporary enclosure must serve four distinct, often competing masters:

- Animal Welfare: It must provide physical and psychological complexity.

- Visitor Experience: It must educate and inspire through immersion.

- Safety: It must offer absolute containment reliability.

- Operational Durability: It must withstand the elements and the animals for decades.

This guide serves as a detailed framework for planning, designing, and specifying materials for these complex structures. While architectural flair creates the shape of the habitat, it is the choice of materials—specifically the containment mesh—that dictates its function. A zoo animal enclosure is only as viable as its barrier system. As we navigate the principles of design, we will examine why the shift toward high-tensile, handwoven stainless steel mesh is not merely an aesthetic trend, but a foundational necessity for the future of zoological containment.

Part 1: Foundational Principles of World-Class Zoo Enclosure Design

Designing a successful zoo animal enclosure requires a holistic approach that synthesizes biology, engineering, and landscape architecture. Before a single beam is erected or a mesh panel is tensioned, the following principles must be codified in the design brief.

1.1 Safety & Containment: The Non-Negotiable

The primary function of any zoo animal enclosure is containment. If a habitat fails in this regard, all other design elements become irrelevant. Modern containment design operates on the principle of “redundancy without obstruction.”

- Primary Containment Lines: This is the physical barrier stopping the animal. It must be rated for the species’ maximum impact force, bite pressure, and manipulation capability.

- Secondary Barriers: Often invisible to the public, these are the backup systems (e.g., overhangs, electrical hot-wires, or vestibules) that prevent escape if the primary line is breached or during keeper access.

- Buffer Zones: The space between the public and the containment line. This prevents physical contact and disease transmission while maintaining the illusion of proximity.

1.2 Animal Welfare & Behavioral Needs

The “Captive Environment” concept suggests that an enclosure is not just a space to exist, but a tool to elicit natural behaviors. A well-designed zoo animal enclosure acts as a behavioral enrichment device in itself.

- Verticality and Volume: For arboreal species (primates, leopards), floor space is less relevant than cubic volume. The enclosure design must support vertical climbing structures, sway poles, and high resting platforms.

- Choice and Control: Animals must have the agency to choose their environment. This requires microclimates (sun vs. shade, heated rocks vs. cool pools) and retreat areas where they can withdraw from public view.

- Dynamic Complexity: The physical structure should allow for change. Fixed concrete creates static environments; flexible mesh structures allow for the suspension of new feeder lines, ropes, and puzzles that change the habitat’s challenge level daily.

1.3 Naturalism & Habitat Replication

The “suspension of disbelief” is crucial for the visitor and beneficial for the animal. We are moving away from architectural hardscapes toward “landscape immersion.”

- The Invisible Barrier: The goal is to dissolve the boundary between the viewer and the viewed. This is where material choice is critical; heavy bars disrupt the eye, whereas fine, dark-oxide stainless steel mesh disappears against a forest background, visually merging the visitor’s space with the animal’s habitat.

- Authentic Substrates and Planting: The enclosure must support living vegetation. This requires soil depth planning and irrigation integration. The containment mesh must be robust enough to allow vines and creepers to grow on it without structural compromise, eventually creating a “green wall.”

1.4 Visitor Experience & Education

Education happens when visitors are engaged. The “views and blinds” technique is essential here. Rather than a panoramic view of the entire zoo animal enclosure (which makes animals feel exposed), modern designs offer curated “windows” or “blinds.”

This creates a sense of discovery. Visitors must look for the animal. When the barrier is nearly invisible—such as a handwoven stainless steel mesh—the encounter feels intimate and immediate, increasing the emotional impact and, subsequently, the educational retention.

1.5 Operational Practicality

A zoo animal enclosure must be workable. Keepers are the daily users of the space.

- Access: Can a keeper safely enter to clean? Are there shift doors that are easy to operate but impossible for animals to open?

- Veterinary Care: Does the design include squeeze cages or training walls where animals can present body parts for voluntary injection or inspection?

- Maintenance: How often does the containment material need painting or repair? In high-traffic zoos, shutting down a popular exhibit for barrier maintenance is a revenue loss. Materials must be chosen for “install and forget” longevity.

Part 2: The Critical Role of Materials: Choosing the Right Enclosure Mesh

If the structural steel is the skeleton of a zoo animal enclosure, the mesh is its skin. It is the interface between the animal and the world. Choosing the containment mesh is arguably the most critical specification decision an architect will make.

2.1 Why the Mesh System is the Backbone

The mesh system dictates the structural load of the support poles, the transparency of the exhibit, and the safety of the animals. A heavy, rigid mesh requires massive, intrusive support columns. A lightweight, high-tensile mesh allows for soaring, lightweight structures (like tent or dome aviaries) that provide immense volume with minimal visual weight.

2.2 Material Comparison: Pros and Cons

When specifying mesh for a zoo animal enclosure, three materials dominate the market. Understanding their lifecycle costs and performance is vital.

Galvanized Steel (Chain Link/Welded)

- Pros: Low initial material cost; readily available.

- Cons: High lifecycle cost. Galvanized coatings inevitably degrade, especially in humid environments or where animals climb (wearing off the zinc). This leads to rust, structural weakening, and aesthetic blight. Zinc ingestion can also be toxic to certain psittacines (parrots) and carnivores.

- Verdict: Acceptable for perimeter fencing, but substandard for primary animal habitats.

Powder-Coated Steel

- Pros: Better initial aesthetics than galvanized; color options available.

- Cons: The “Achilles Heel” of powder coating is chipping. Once an animal scratches the coating or a tool chips it, moisture gets underneath, causing rust to spread unseen. It requires regular touch-ups and eventually total replacement.

- Verdict: Suitable for low-impact areas, but risky for animals with claws or beaks.

Stainless Steel (The Professional Standard)

- Pros: Stainless steel (specifically grades 304 and 316) is the gold standard for modern zoo animal enclosure design.

- Corrosion Resistance: It is virtually impervious to rust, urine, and humidity.

- Tensile Strength: It offers the highest strength-to-weight ratio, allowing for thinner wires and better visibility.

- Longevity: A lifespan of 30+ years reduces the “total cost of ownership” significantly below galvanized options.

- Non-Toxic: Safe for all species.

- Flexibility: Handwoven varieties can conform to irregular geometric shapes (hyperbolic parabolas) typical in modern tent structures.

- Verdict: The required specification for world-class zoos aiming for accreditation and long-term sustainability.

2.3 Key Specifications for Stainless Steel Zoo Mesh

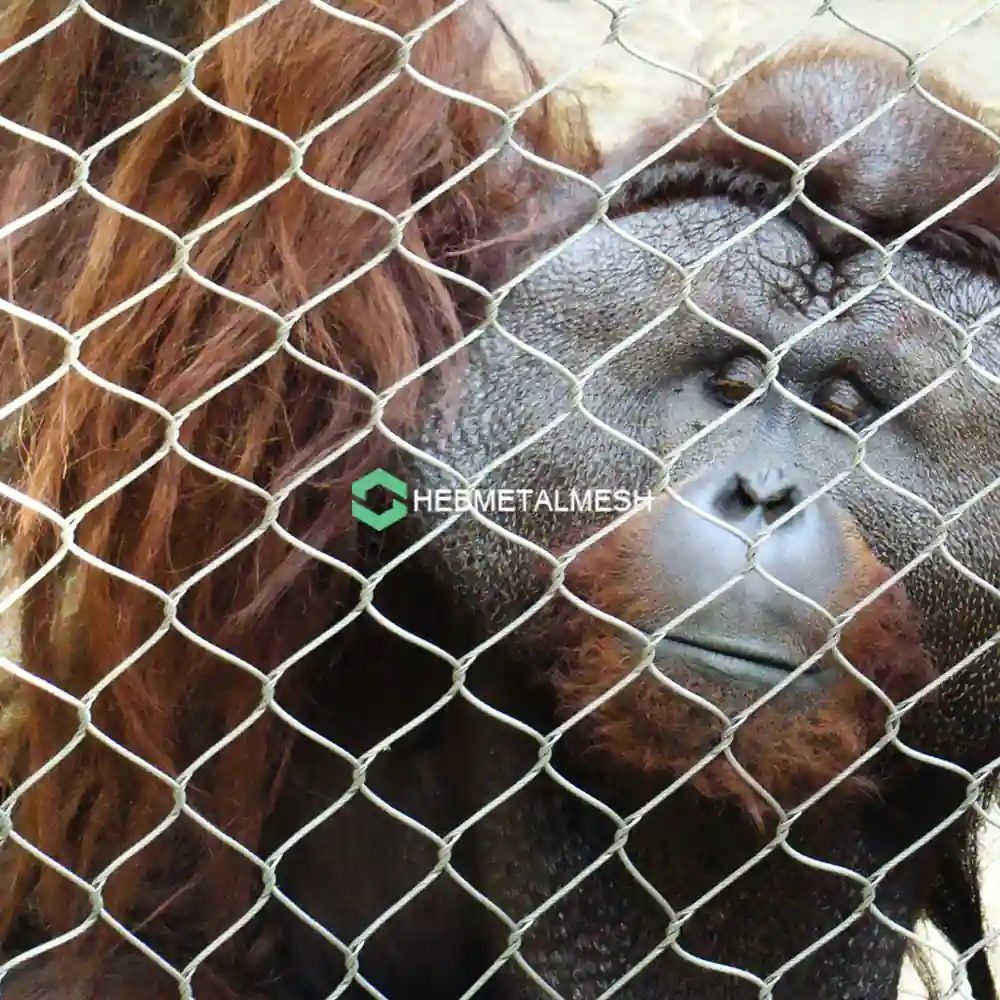

At Hebmetalmesh, we specialize in handwoven stainless steel netting. Unlike welded mesh, which has rigid weak points at every cross-section, handwoven mesh acts like a fabric. It absorbs impact energy by flexing rather than breaking.

When specifying Hebmetalmesh for your zoo animal enclosure, focus on these three variables:

A. Weave Type: Handwoven Interlock

Handwoven mesh involves interlocking standard wire ropes with stainless steel ferrules or knotting them. This structure is superior because if one wire is cut (vandalism or accident), the mesh does not unravel. The “fabric-like” quality allows architects to drape the mesh over rockwork or stretch it into 3D tunnels.

B. Mesh Size (Aperture) Selection

The aperture must be small enough to prevent the animal’s head or paws from getting stuck, but large enough to maximize visibility.

- 1″ x 1″ (25mm): Ideal for small birds, small primates (marmosets), and rodents. Prevents the entry of local wild pests (rats/sparrows).

- 1.5″ x 1.5″ (38mm): The workhorse size for mid-sized birds (parrots, toucans) and smaller monkeys.

- 2″ x 2″ (50mm): General purpose for medium primates (lemurs, gibbons) and small carnivores.

- 3″ x 3″ (76mm) & 4″ x 4″ (102mm): Specified for large animals—tigers, lions, leopards, and bears—and for background perimeter fencing where high transparency is desired.

C. Wire Thickness (Cable Diameter)

This determines the breaking load.

- 3/64″ (1.2mm): Ultra-lightweight for small bird aviaries.

- 1/16″ (1.6mm) & 5/64″ (2.0mm): The standard specification for most primate and mammal enclosures.

- 3/32″ (2.4mm) & 1/8″ (3.2mm): Heavy-duty specification. Mandatory for large carnivores (big cats, bears) and robust primates (gorillas, orangutans) capable of exerting massive force.

D. Finish Options

Black Oxide: The architect’s choice for immersion. An oxidation process turns the steel matte black. It does not peel like paint. In a shadowed, planted zoo animal enclosure, black mesh absorbs light and becomes virtually invisible to the human eye.

Natural (Bright): Reflects sunlight. Best for dark environments or where the mesh is a featured architectural element.

BestSeller: Durable Zoo Animal Enclosure Mesh | 1″-4″ Stainless Steel | BOSS Series Net

Ensure the highest standard of safety, visibility, and longevity for your habitat with the BOSS Series Net Zoo Animal Enclosure. Expertly engineered for modern zoos, safari parks, aviaries, and rehabilitation centers, this heavy-duty stainless steel mesh is the definitive solution for secure and ethical animal containment.

Crafted from premium Stainless Steel 304 and finished with a resilient Black Oxide coating, this enclosure mesh resists corrosion, weathering, and animal wear far better than galvanized or aluminum alternatives. Its aesthetic dark matte finish reduces glare, providing a more natural backdrop for habitats and better visitor viewing experiences.

Precision-Built for Diverse Habitat Needs

- Superior Material: Stainless Steel 304 ensures exceptional tensile strength and resistance to rust, corrosion, and harsh environmental elements.

- Versatile Mesh Sizes: Choose from 1″ to 4″ mesh openings to safely contain a wide range of species, from small birds and reptiles to large primates and climbing mammals.

- Heavy-Duty Gauge: With a wire thickness ranging from 3/64″ to 1/8″, this mesh provides formidable strength to withstand significant force and persistent activity.

- Large, Efficient Rolls: Supplied in convenient 10 feet high x 60 feet long rolls, facilitating efficient installation on large-scale enclosure frames and structures.

Key Features & Benefits:

- Unmatched Safety & Security: Prevents animal escapes and protects against predator intrusion with its robust, tamper-resistant design.

- Animal & Keeper Friendly: Smooth, uniform mesh prevents injury to claws and beaks, while providing clear sightlines for monitoring animal health.

- Long-Term Durability: The Black Oxide Stainless Steel construction offers a lifespan that outperforms and outlasts standard coated meshes, delivering a superior return on investment.

- Enhanced Aesthetics: The low-reflectance black finish blends seamlessly into natural surroundings, improving habitat realism.

- Fully Customizable: We provide tailored solutions. Need a different panel size, mesh combination, or cut-to-size panels? We can manufacture to your exact project specifications.

Primary Applications:

- Prate Enclosures (Monkey, Ape, Lemur)

- Large Aviaries and Bird Flight Cages

- Reptile and Small Mammal Habitats

- Protective Barriers for Windows and Openings

- Decorative and Functional Safety Barriers in Animal Parks

Invest in the Gold Standard of Animal Care and Containment.

Product: Series Net Zoo Animal Enclosure | BOSS

Material: Stainless Steel 304 with Black Oxide Finish

Mesh Sizes: 1″, 1.5″, 2″, 3″, 4″ (Custom sizes available)

Standard Roll Size: 10 ft (Height) x 60 ft (Length)

Price Range: $188.00 – $2,875.00 (Varies based on mesh size and configuration)

Ready to secure your habitat with the best? Contact Hebmetalmesh today for a quote on our standard rolls or to discuss your custom zoo animal enclosure requirements.

Click here to view the BOSS Series Net Zoo Mesh and order directly on our product page.

Part 3: Application-Focused Design Considerations

Different taxons present unique engineering challenges. Here is how specific material choices solve them.

3.1 For Large Carnivores (Big Cats, Bears, Wolves)

The Challenge: Impact and Digging. A charging tiger hits a fence with immense kinetic energy. Bears are relentless testers of weak points and powerful diggers. The Solution:

- Tensile Absorption: Use Hebmetalmesh handwoven mesh (1/8″ or 3/32″ diameter). The flexibility absorbs the shock of a lunging animal better than a rigid welded fence, which might shear.

- Kick-in Barriers: The enclosure design must include a “dig barrier” where the mesh extends underground or connects to a concrete footer.

- Overhangs: Even non-climbing predators can scale vertical fences. Inward-curving mesh overhangs are easily achieved with flexible stainless netting.

3.2 For Primates (Monkeys, Apes)

The Challenge: Intelligence and Dexterity. Primates will untwist wire, pick at coatings, and dismantle joined fencing. They also require 3D space utilization. The Solution:

- Tamper-Proof: Handwoven stainless steel mesh has no loose ends. The ferrules are swaged under high pressure, making them impossible for fingers to pry open.

- Safety: The surface is smooth. Unlike galvanized chain link which can have sharp “tags” that cut primate hands, stainless mesh is safe for swinging and climbing.

- Integrated Structures: You can attach ropes and firehose hammocks directly to the mesh walls (within load limits), turning the barrier into a climbing apparatus.

- Customization: Primate enclosures often feature tunnels (chutes) transferring animals between habitats. Flexible mesh tubes are the ideal solution here.

3.3 For Walk-In Bird Aviaries & Flight Enclosures

The Challenge: Volume and Visibility. Birds need flight space. Heavy supports reduce flight paths. The Solution:

- Lightweight Engineering: Using 3/64″ or 1/16″ cable mesh allows for massive tent structures suspended from pylons. This maximizes the internal flight volume.

- Soft Barriers: Rigid wire can injure birds if they fly into it during a panic. Flexible cable mesh acts like a safety net, “catching” the bird gently.

- Predator Exclusion: Using a 1″ x 1″ aperture ensures the exhibit birds stay in, but also prevents local predators (hawks, raccoons) from entering.

3.4 For Reptiles & Amphibians

The Challenge: Corrosion. Reptile houses are often kept at tropical humidity (80%+) with frequent misting. The Solution:

- Imperviousness: Galvanized steel will rot in a reptile house within years. Stainless steel (Grade 304/316) is unaffected by the humidity.

- Heat & Light Transmission: Mesh tops allow for the installation of UV and heat lamps above the enclosure, penetrating the mesh without melting or degrading it (unlike nylon netting).

Part 4: Technical & Practical Implementation

For the architect and project manager, the logistics of installation are as important as the material properties.

4.1 Customization and Fabrication

One of the greatest inefficiencies in traditional zoo animal enclosure construction is the “patchwork” approach—stitching together small rolls of fencing. This creates weak points and increases labor costs.

The Hebmetalmesh Advantage: We understand the scale of modern zoos. We fabricate custom-sized panels and maxi rolls up to 30′ x 60′ (and larger upon request).

- Seamless Design: A single continuous sheet can span the entire height of a giraffe house or the width of an aviary.

- Structural Integrity: Fewer seams mean fewer potential points of failure.

- Aesthetics: A continuous mesh surface looks cleaner and more professional.

4.2 Installation Best Practices

Designing the zoo animal enclosure is step one; ensuring proper installation is step two.

- Framing: While the mesh is stainless, the frame is often structural steel. Ensure isolation between dissimilar metals if necessary to prevent galvanic corrosion, although stainless mesh pairs well with galvanized frames.

- Tensioning: Stainless cable mesh functions best under tension. Design perimeter frames with attachment points for tension cables or turnbuckles. A taut mesh is transparent; a loose mesh sags and becomes visible.

- Anchoring: For ground interactions, verify the substrate. In sandy soil, deep concrete footers are required to anchor the bottom tension cable.

4.3 Long-Term Maintenance of Stainless Steel Mesh

The operational budget of a zoo is often tight. Stainless steel mesh is an investment in lowering Operational Expenditure (OpEx).

- Self-Cleaning: In outdoor environments, rain is usually sufficient to clean the mesh.

- Sterilization: For disease control, stainless mesh can be pressure washed with hot water and disinfectants without fear of corrosion or damaging a coating.

- Visual Inspection: Because it doesn’t rust, safety inspections are easier. Keepers look for mechanical damage rather than scrubbing away rust to check integrity.

Conclusion: Investing in a Legacy of Care and Safety

The modern zoo animal enclosure is a complex intersection of stewardship, science, and spectacle. As we move further into an era of conservation-focused design, the structures we build must reflect our commitment to the animals in our care.

A habitat designed with substandard materials is a temporary solution that compromises safety and welfare. Conversely, an enclosure built with professional-grade, handwoven stainless steel mesh is a legacy asset. It signifies a commitment to:

- Uncompromising Safety for animals and keepers.

- Optimal Wellness through naturalistic, complex environments.

- Unrivaled Visitor Experiences through invisible barriers.

- Fiscal Responsibility through decades of maintenance-free performance.

At Hebmetalmesh, we provide more than just wire; we provide the framework for world-class habitats. With years of global experience supplying premium zoo mesh to wildlife parks and zoological gardens, we understand the nuances of your project.

Ready to design the next generation of habitats? We invite architects, curators, and facility managers to leverage our expertise. Whether you need a custom 30-foot aviary panel or a heavy-duty tiger containment system, we can fabricate to your exact specifications.

[Explore our Catalog of Stainless Steel Zoo Mesh] or [Contact Us Today] to discuss your specific habitat requirements and receive a custom quote. Let’s build a better world for wildlife, together.