Wire mesh plays a pivotal role in the design and construction of zoo enclosures.

It provides a delicate balance between ensuring animal safety and enhancing visitor visibility.

This article delves into the various types of wire mesh used in zoo enclosures, their unique properties, and their specific applications.

We will also explore key considerations when selecting wire mesh, installation best practices, and future trends in this field.

The Significance of Wire Mesh in Zoo Enclosure Design

Wire mesh is a versatile material used extensively in zoo enclosures.

Its primary function is to provide a secure environment for animals while allowing visitors to observe them closely.

The choice of wire mesh can significantly impact the overall design of the enclosure, influencing factors such as visibility, durability, and animal safety.

Therefore, understanding the properties and applications of different types of wire mesh is crucial for anyone involved in the design, construction, or maintenance of zoo enclosures.

Types of Wire Mesh for Animal Enclosures

There are several types of wire mesh used in zoo enclosures.

Each type has its unique properties and applications.

The most common types include stainless steel wire mesh, galvanized wire mesh, woven wire mesh, and welded wire mesh.

The choice of wire mesh depends on various factors such as the species of animal, the size of the enclosure, and the specific requirements of the zoo.

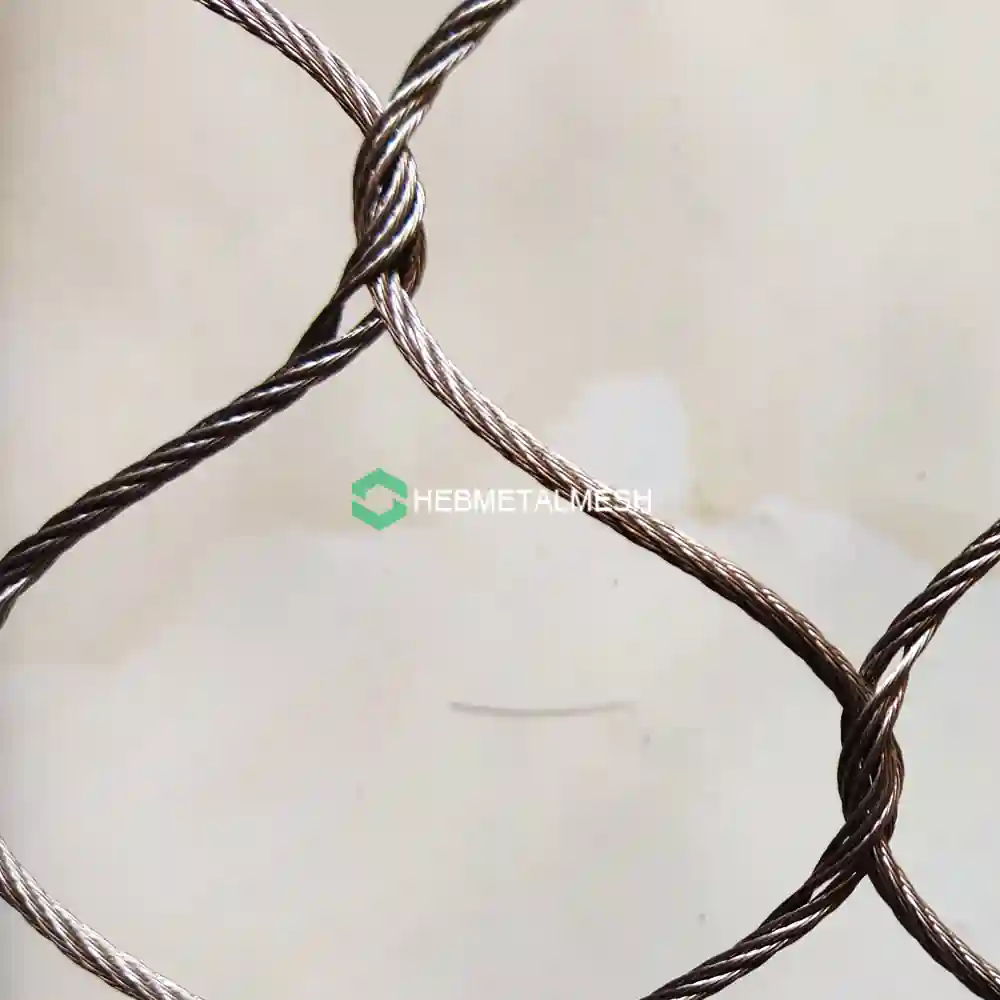

Zoo Mesh

When it comes to selecting the perfect mesh for zoo animal enclosures, the top choice is definitely the high-quality zoo mesh offered by Hebmetalmesh. This specially designed mesh provides the ideal balance of durability, flexibility, and safety for all types of zoo animals. With its strong construction and reliable performance, Hebmetalmesh zoo mesh is the preferred option for zoos and wildlife parks around the world. Choose Hebmetalmesh for your zoo animal enclosures and ensure the safety and well-being of your animals.

Stainless Steel Wire Mesh

Stainless steel wire mesh is a popular choice for zoo enclosures.

It is known for its durability and resistance to corrosion, making it suitable for enclosures housing a wide range of animals.

Galvanized Wire Mesh

Galvanized wire mesh is another commonly used material.

It offers protection against rust at a lower cost, making it a cost-effective option for many zoos.

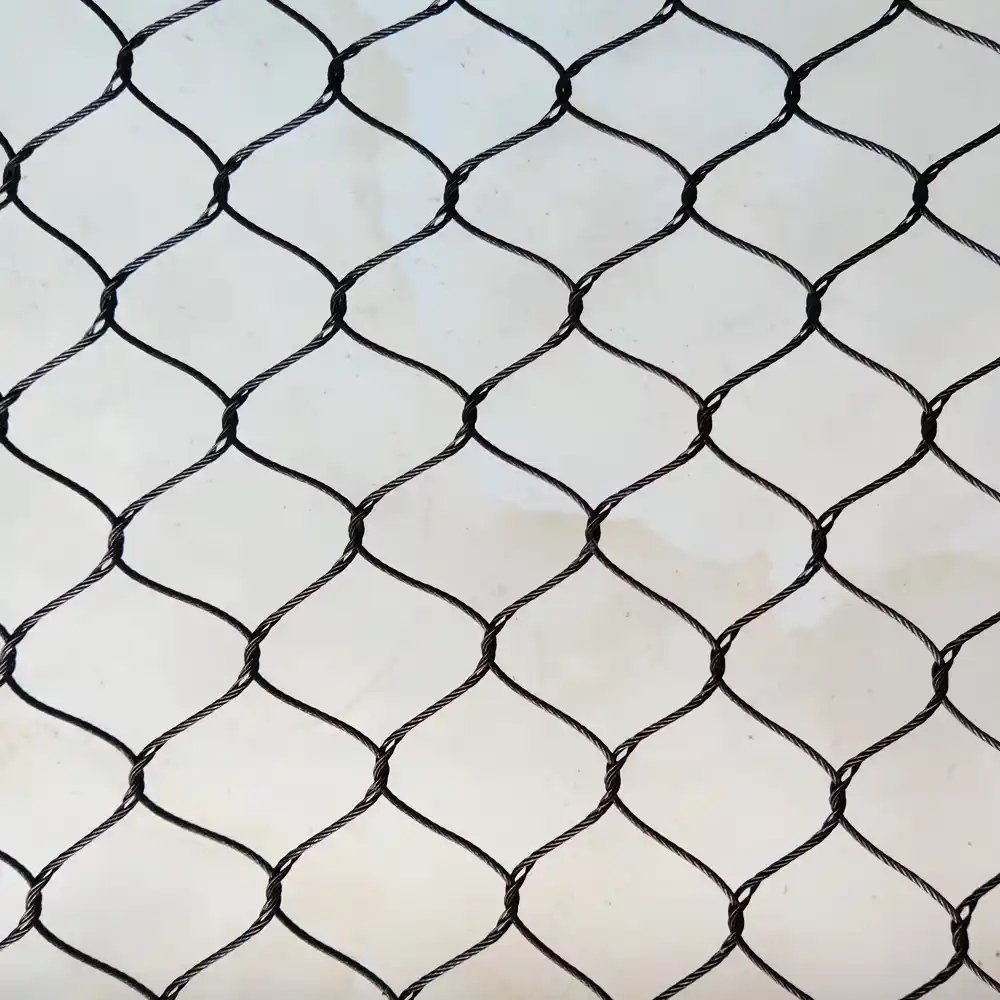

Woven vs. Welded Wire Mesh

Woven wire mesh allows for flexibility and is suitable for enclosures with complex shapes.

On the other hand, welded wire mesh is known for its strength and uniformity, making it ideal for larger, more powerful animals.

Key Considerations for Selecting Wire Mesh

When selecting wire mesh for zoo enclosures, several factors need to be considered.

These include the mesh size, gauge thickness, visibility, and animal safety.

Each of these factors plays a crucial role in ensuring the effectiveness and longevity of the enclosure.

Here are some key considerations:

- Mesh size and gauge thickness

- Visibility and animal safety

Mesh Size and Gauge Thickness

The mesh size and gauge thickness of the wire mesh are critical considerations.

The mesh size must be chosen carefully to prevent animals from escaping or getting injured, while the gauge thickness affects the strength and durability of the enclosure.

Visibility and Animal Safety

Visibility is a key factor in zoo enclosure design, enhancing the visitor experience.

At the same time, animal safety is paramount; the wire mesh should not have sharp edges or points that could harm the animals.

Installation and Maintenance of Zoo Enclosures with Wire Mesh

Proper installation of wire mesh is crucial to ensure the safety of both animals and visitors.

Regular maintenance, including ease of cleaning and resistance to animal wear, is also important.

The need for regular inspections and potential replacement of wire mesh to ensure ongoing safety cannot be overstated.

Advancements and Future Trends in Wire Mesh for Zoos

The advancements in wire mesh technology have greatly benefited modern zoo enclosure design.

New materials and manufacturing techniques have led to stronger, more durable, and visually appealing wire mesh products.

Looking forward, we can expect further innovations that will continue to enhance the safety, functionality, and aesthetics of zoo enclosures.