Introduction to Safety Mesh

Safety mesh is an innovative and vital component used in a variety of industries, particularly in construction, architecture, and manufacturing. This specialized netting, often made from handwoven stainless steel, serves multiple purposes that contribute to the overall safety and integrity of structures. The primary function of safety mesh is to provide a secure barrier that prevents falls and protects both workers and materials, making it an indispensable tool in high-risk environments.

The significance of selecting top-quality materials when it comes to safety mesh cannot be overstated. High-grade stainless steel offers superior strength, durability, and corrosion resistance, ensuring that the mesh can withstand both environmental factors and the rigors of heavy-use applications. This is especially crucial in construction settings, where safety is a paramount concern. By opting for premium safety mesh, businesses not only enhance safety protocols but also reduce the likelihood of accidents and associated costs, ultimately contributing to a more secure working environment.

Safety mesh is not limited to construction; its applications span various sectors, including architecture, where it is increasingly used in safety railing systems and cladding. In manufacturing, safety mesh can serve as protective barriers around machinery, preventing accidents while simultaneously maintaining visibility. The versatility of safety mesh enables it to be adapted to meet the specific needs and regulations of different industries, further solidifying its importance in ensuring safety and compliance.

In summary, safety mesh is a fundamental element in modern industry, serving as a critical line of defense against accidents. The choice of materials directly influences its effectiveness, making it essential for companies to prioritize quality and performance when selecting safety mesh solutions.

Why Choose Handwoven Stainless Steel Netting?

Handwoven stainless steel netting is rapidly gaining recognition as a superior option in safety mesh applications due to the distinctive advantages it offers. Unlike conventional safety nets, handwoven techniques ensure a heightened level of durability and strength, making this material exceptionally reliable in various environments. The intricate weaving process results in a tighter and more resilient structure, allowing it to withstand significant stress and impact, something that is critical in safety applications.

Moreover, the use of stainless steel provides an inherent resistance to corrosion and rust, ensuring longevity even in challenging outdoor conditions. Because handwoven stainless steel netting is designed to endure extreme environmental factors, it significantly reduces the need for frequent replacements, providing economic benefits over time. This is particularly advantageous in industrial settings where consistency and reliability are paramount.

In addition to its robust performance, the aesthetic appeal of handwoven stainless steel adds another layer of value. The intricate patterns created during the weaving process not only serve practical safety functions but also contribute to a visually appealing design that can enhance architectural projects. This dual benefit of aesthetics and safety ensures that the netting does not compromise style for strength; instead, it complements the overall design while fulfilling safety requirements.

Furthermore, handwoven stainless steel netting can be customized to meet specific project needs, offering versatility that traditional safety mesh products may lack. This customization ranges from variations in mesh size to different weaving styles, providing designers and safety professionals the flexibility to achieve their desired results without sacrificing quality.

Ultimately, handwoven stainless steel netting stands out as a formidable choice in the realm of safety mesh, offering an exceptional blend of durability, aesthetics, and versatility that meets the demands of both practical applications and design aspirations.

Color Options: Nature and Black Oxide

The handwoven stainless steel netting known as safety mesh is available in two primary color options: nature color and black oxide. Each of these choices offers distinctive aesthetic qualities and functional benefits, allowing for diverse applications in various architectural settings.

The nature color, a warm, earthy tone, closely resembles the appearance of natural metals. This color option is particularly well-suited for environments where integration with surrounding elements is essential. It complements organic designs and blends effortlessly with natural settings, such as gardens, parks, and rustic architecture. The psychological impact of the nature color can evoke feelings of warmth and comfort, making it an excellent choice for areas designed for relaxation and interaction with nature.

In contrast, the black oxide finish provides a sleek, modern appearance. This color option is ideal for contemporary architectural styles, characterized by bold lines and striking contrasts. Black oxide safety mesh can lend a sophisticated edge to buildings, enhancing their visual appeal while maintaining high levels of safety and functionality. The use of a darker color can create a more dramatic effect and may be particularly beneficial in urban settings, where it can help draw attention to the structure while emphasizing safety features.

Ultimately, the choice between nature color and black oxide comes down to the specific requirements of the project and the desired aesthetic effect. Architects and designers must consider how the selected color can influence the overall atmosphere of the environment, as well as its compatibility with other materials and design elements. By thoughtfully choosing the right color for the safety mesh, one can achieve a blend of safety and beauty that is both functional and visually striking.

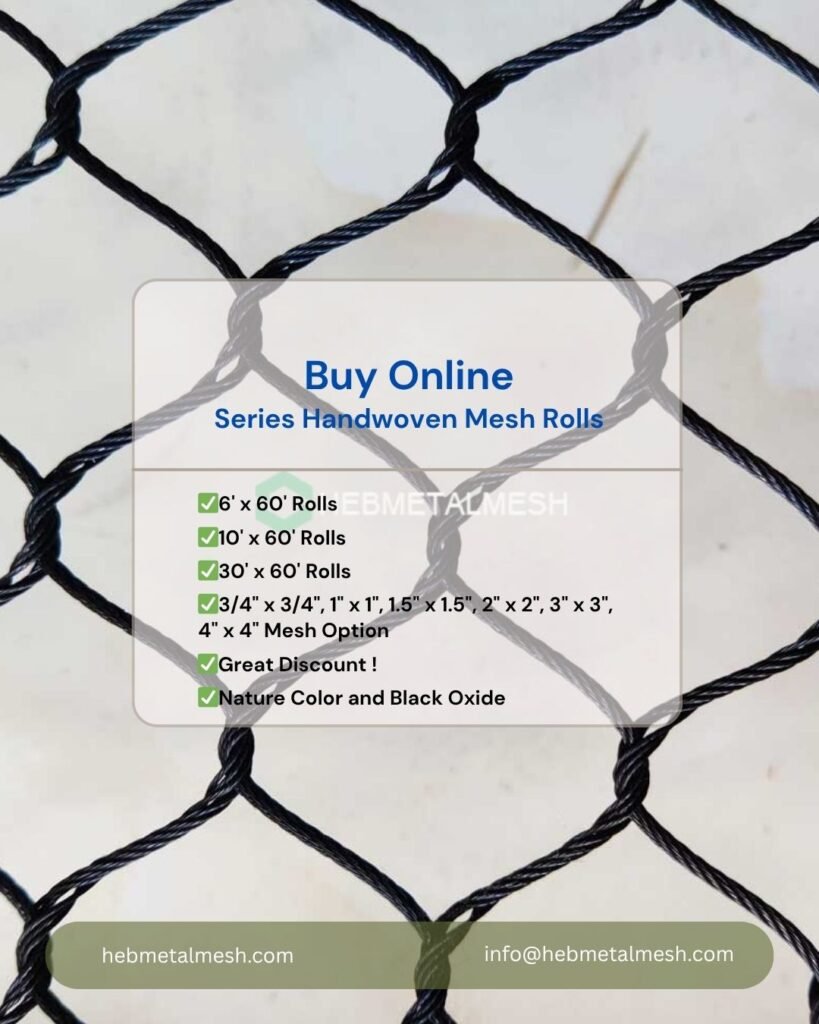

Customized Roll Options to Fit Your Needs

Safety mesh products offer unparalleled versatility, particularly when it comes to customization. Clients increasingly seek tailor-made solutions that meet their specific project requirements, and we understand the importance of accommodating these needs. Each project, whether in manufacturing or construction, may have unique constraints in terms of size and functionality, which is where our customized roll options come into play.

One of the primary benefits of our safety mesh products is the ability to adjust the dimensions according to the project’s specifications. Clients can select the width and length of the roll, allowing for seamless integration into various environments. Whether it is for use in industrial sites, construction projects, or residential applications, having the option to customize dimensions ensures that the safety mesh fits perfectly within the required space.

Additionally, density is an essential factor that can be tailored to meet specific safety standards or operational demands. Our safety mesh is available in various mesh sizes and thicknesses, providing clients with the ability to choose a configuration that optimally balances strength and flexibility. The appropriate density is crucial for ensuring the safety and integrity of structures, especially in applications where high levels of exposure to stress or environmental factors are anticipated.

Furthermore, we offer flexibility in roll sizes, which can be advantageous for large-scale projects. Clients may require longer rolls to minimize joints and seams, ensuring a more continuous application. This customization not only enhances safety but also improves the overall aesthetic of the installation. By being able to cater our safety mesh products to the unique needs of each project, we facilitate a more effective and efficient implementation for our clients.

Handwoven Technology: The Craftsmanship Behind Safety Mesh

The craftsmanship involved in creating handwoven stainless steel netting, commonly known as safety mesh, is a testament to both skill and innovation. The process begins with the careful selection of high-quality stainless steel wire, which is known for its durability and resistance to corrosion. This selection is crucial as it directly impacts the longevity and reliability of the safety mesh once installed. Artisans skilled in this precise craft utilize traditional handweaving techniques that have been refined over generations, ensuring that each piece of safety mesh is not just functional but also an embodiment of artistry.

The weaving process itself involves several intricate steps. First, the stainless steel wires are meticulously threaded through one another in a crisscross pattern, which contributes to the mesh’s overall strength and stability. Each artisan brings their expertise to this process, adjusting the tensions and angles to achieve an optimal balance. This painstaking attention to detail results in a safety mesh that can withstand significant pressure and environmental factors, making it suitable for various applications, ranging from construction sites to art installations.

Moreover, the commitment to sustainable practices plays a vital role in the craft of safety mesh production. Many artisans prioritize sourcing their materials from responsible suppliers who adhere to ethical harvesting methods. This not only supports environmental preservation but also ensures that the end product is socially responsible. The handwoven nature of the safety mesh allows for a reduction in waste, as artisans create netting with minimal excess material. This focus on sustainability, combined with skillful craftsmanship, enhances the value of safety mesh, ensuring it remains a trusted choice for those seeking reliable and eco-friendly solutions.

Safety Features and Standards of Handwoven Stainless Steel Netting

Handwoven stainless steel netting serves as a robust safety mesh that is commonly used across various industries. Its prominent safety features include excellent tensile strength, corrosion resistance, and adaptability to different environments. These attributes make it an ideal candidate for applications that require both functionality and durability. For instance, in construction, the netting provides essential support for scaffolding and prevention of debris from falling, ensuring the safety of personnel on site.

The safety mesh also adheres to numerous regulatory standards designed to ensure its effectiveness and reliability. Organizations such as the American National Standards Institute (ANSI) and the Occupational Safety and Health Administration (OSHA) oversee these standards, which define the criteria for performance, safety, and durability. Compliance with these regulations is imperative because it not only enhances the product’s credibility but also mitigates risks associated with its use across various applications. This is particularly crucial in sectors like mining, where the integrity of safety barriers can be the difference between a secure work environment and potential hazards.

Real-world examples demonstrate how adherence to these safety features and standards has resulted in significant positive outcomes. For instance, a notable case involved the installation of handwoven stainless steel netting in a high-rise construction project. Following safety standards meticulously, the facility reported a fifty percent reduction in accidents related to falling objects. Such instances not only underscore the effectiveness of this safety mesh but also the importance of regulatory compliance in maintaining workplace safety.

As industries continue to evolve, the demand for secure and compliant safety solutions remains paramount. Handwoven stainless steel netting stands out through its innovative design and consistent adherence to established safety standards, making it an indispensable resource in ensuring the safety of personnel and assets.

The Versatility of Safety Mesh Across Industries

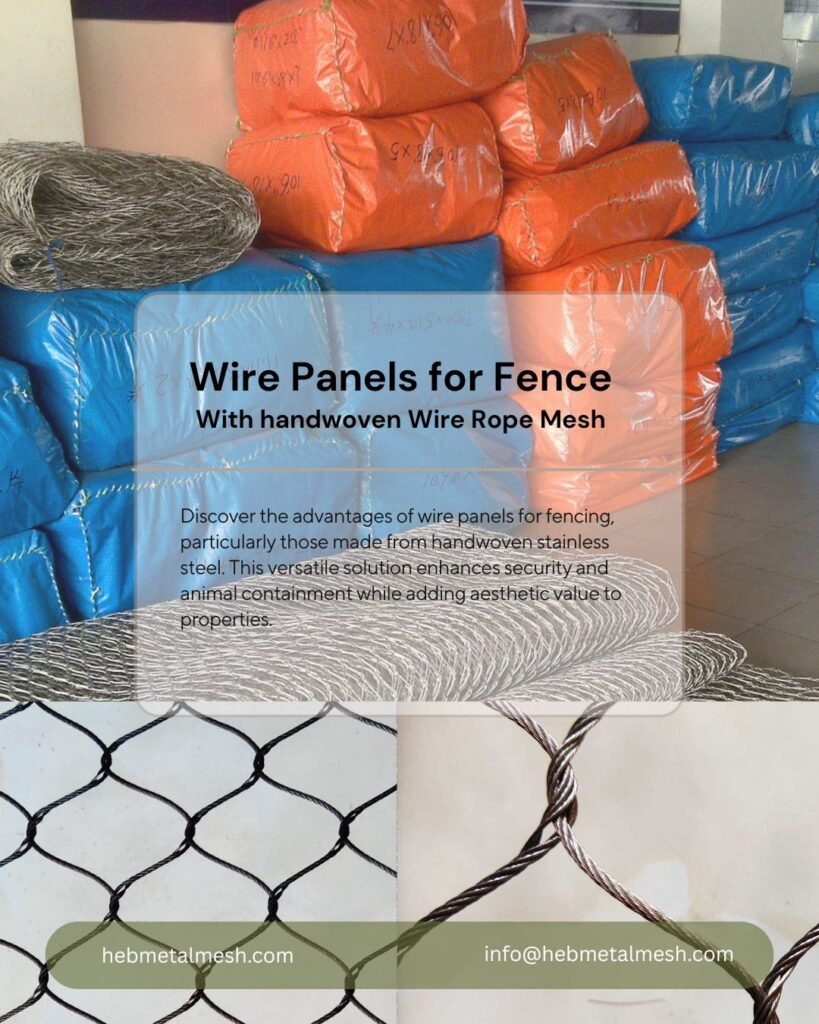

Safety mesh, particularly in the form of handwoven stainless steel netting, has emerged as a pivotal solution across a variety of industries. This innovative material not only prioritizes safety but also lends a niche aesthetic appeal that is increasingly valued in contemporary applications. Its strength and durability make it ideally suited for critical sectors such as construction, manufacturing, and even artistic endeavors.

In the construction industry, safety mesh serves multiple functions; it is often utilized as protective barriers during the erection of scaffolding. By providing an additional layer of security, the mesh ensures that workers are well-protected from potential falls and debris. Its lightweight yet robust nature simplifies installation while retaining structural integrity. Furthermore, safety mesh helps facilitate airflow and visibility, enhancing safety without compromising the working environment’s functionality.

Manufacturers are also capitalizing on this versatile material, using safety mesh in machinery to prevent accidental injuries. By encasing gears, sharp edges, and other hazards, the stainless steel netting establishes a barrier that minimizes operational risks. This application is especially crucial in high-traffic areas where the likelihood of human interaction is increased. The resilience of safety mesh also means it can withstand harsh industrial environments, maintaining its protective qualities over time.

Lastly, in the realm of art installations, safety mesh is redefining creative freedom. Artists leverage its unique characteristics to design intricate sculptures and installations that challenge traditional perceptions of safety and space. By harmonizing structure with aesthetic appeal, these artists exemplify how safety mesh can feature prominently in creative expressions while ensuring public safety remains at the forefront.

Thus, the versatility of safety mesh spans a broad spectrum of applications, underscoring its significance as a material that combines safety with elegance in various industrial contexts.

Case Studies: Success Stories Using Handwoven Safety Mesh

Handwoven safety mesh has gained recognition within various industries due to its impressive performance and versatility. A quintessential example is its deployment in construction projects, where it has been utilized to enhance worker safety and minimize potential risks associated with falling objects. In one notable case, a skyscraper project in an urban setting implemented safety mesh around its perimeter. This application significantly reduced the risk of accidents while enabling a seamless workflow for construction crews, thereby fostering an environment of safety and efficiency.

Another compelling instance involved a commercial winery that sought to protect its grapes from birds and other pests. By using handwoven stainless steel netting, they were able to create a secure barrier around their vineyards. This not only safeguarded their crop yield but also maintained the aesthetics of the vineyard, as the netting is discreet and unobtrusive. This case exemplifies the dual functionality of safety mesh as both a protective and aesthetic element in agricultural settings.

Furthermore, in a recent educational facility renovation, safety mesh was integrated into the design of a new playground area. The handwoven nature of the safety mesh ensured durability and flexibility, providing a reliable solution for safeguarding children while allowing for creative playground structures. Parents and educators alike appreciated this integration, noting the peace of mind it provided, as well as the enhancement of the area’s overall safety profile. These varied use cases emphasize the adaptability of safety mesh across different sectors, proving its value as a crucial component in both safety and functionality.

Conclusion

As we wrap up our discussion on the significance of safety mesh, it becomes abundantly clear that the choice of material plays a crucial role in ensuring both safety and durability. Handwoven stainless steel netting stands out as an exemplary option due to its exceptional strength, resilience, and adaptability for various applications. Unlike traditional safety nets, this innovative alternative not only provides heightened security but also boasts an aesthetically pleasing appearance, which can align seamlessly with modern architectural designs.

The benefits of using handwoven stainless steel mesh are multi-faceted. Its corrosion-resistant properties ensure longevity, making it a wise investment for those prioritizing safety in both residential and commercial settings. Furthermore, the versatility of this material allows for its utilization in diverse environments, ranging from protective barriers in construction zones to elegant fencing around private properties. By incorporating safety mesh into your plans, you are not just enhancing security; you are contributing to a more robust and visually appealing infrastructure.

We encourage readers to carefully consider the options available in handwoven stainless steel netting. It is imperative to invest in high-quality materials that support safety standards, as this can greatly affect the well-being of individuals exposed to potentially hazardous environments. As you explore your choices in safety solutions, remember that the right safety mesh can provide peace of mind, prevent accidents, and elevate overall safety standards in your space. Take the next step and investigate the various products available in the market to discover how handwoven stainless steel netting can fit into your safety strategy.

Pingback: What Is Mesh Fabric Netting and Why Is It So Popular