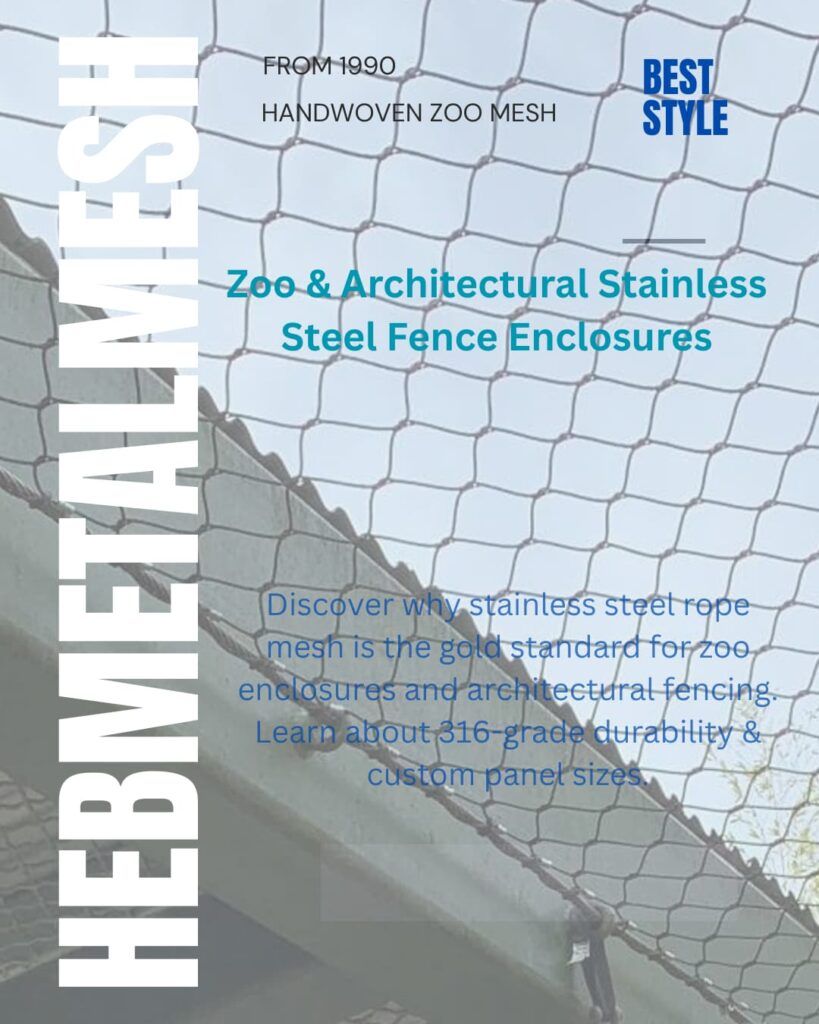

In the world of modern containment and architectural design, the shift from traditional rigid barriers to flexible, high-strength solutions has redefined how we perceive security. Stainless steel fence enclosures, particularly those utilizing handwoven rope mesh, have emerged as the gold standard for projects that refuse to compromise between “unbreakable strength” and “visual elegance.”

Whether you are designing a world-class zoo exhibit, a high-security aviary, or a sophisticated architectural balustrade, the choice of fencing material is the single most critical factor in the project’s long-term success. Traditional chain-link or welded wire often falls short—rusting within years or creating “prison-like” aesthetics that obstruct views. In contrast, stainless steel zoo mesh provides a “transparent” yet formidable barrier that thrives in the harshest environments on Earth.

Article Key Takeaways

Before we dive into the technical specifications and installation complexities, here are the high-level advantages of choosing stainless steel for your next enclosure project:

- Unmatched Longevity: Rated for a 30+ year lifespan, even in coastal or high-humidity environments.

- “Invisible” Visibility: The high transparency of rope mesh (especially in Black Oxide finish) provides an unobstructed view, making the barrier virtually disappear.

- Animal Welfare Priority: Unlike rigid wire, flexible rope mesh acts as a “buffer,” absorbing kinetic energy from impacts to prevent injury to animals or birds.

- Maintenance-Free: Naturally resistant to corrosion, UV rays, and physical “chewing” or “clawing” damage from large predators.

- Customization at Scale: Hebmetalmesh offers custom-woven panels up to 30′ x 60′, allowing for seamless, large-scale installations with zero fabrication waste.

1. Defining the Modern Stainless Steel Fence Enclosure

What exactly makes a stainless steel fence enclosure superior to standard metal fencing? To understand its value, we must look at the material’s molecular structure and the artistry of the weave.

The Anatomy of the Cable

At the heart of every high-end enclosure is the 304 or 316-grade stainless steel wire rope. These cables are not solid strands; they are composed of multiple wires twisted into “strands,” which are then twisted around a core.

- 7 x 7 Construction: Comprising 7 strands of 7 wires each, this is the standard for general fencing, providing a perfect balance of flexibility and breaking strength.

- 7 x 19 Construction: With 19 wires per strand, this cable is significantly softer and more pliable. It is the preferred choice for primate enclosures or areas where the mesh must follow complex, organic curves.

Handwoven vs. Ferruled: The Two Faces of Mesh

When selecting your enclosure, you will encounter two primary styles:

- Handwoven (Knotted) Mesh: This is the signature product of Hebmetalmesh. It is created by hand-interweaving the cables without the use of metal sleeves (ferrules). This makes the mesh lighter, more transparent, and exceptionally flexible. Because there are no rigid points, the energy of an impact is distributed across the entire panel.

- Ferruled (Sleeved) Mesh: This style uses aesthetic metal clips to join the ropes. It offers a more industrial, modern look and is often used in architectural balustrades or safety nets where a specific geometric “stiffness” is desired.

Why 316 Grade is the Industry Benchmark

While Grade 304 is excellent for inland applications, Grade 316 stainless steel contains molybdenum. This addition makes it virtually immune to “pitting” and “crevice corrosion” caused by salt spray. For zoos or residential properties within 10 miles of the ocean, 316-grade mesh is the only choice that guarantees a 30-year rust-free guarantee.

2. Technical Specifications: Engineering the Perfect Enclosure

When designing a professional-grade enclosure, the “one size fits all” approach does not exist. The success of a stainless steel rope mesh project depends on three primary technical variables: Wire Diameter, Aperture (Mesh Opening), and Breaking Load.

Understanding these metrics is the difference between a fence that lasts 30 years and one that fails under the first sign of structural stress.

2.1 Wire Rope Diameter: Choosing Your Strength

The thickness of the wire rope determines the overall tensile strength and “visual weight” of the enclosure. At Hebmetalmesh, we typically categorize wire diameters into three tiers based on the application:

- Light-Duty (1.2mm – 1.6mm): Ideal for small bird aviaries (finches, parakeets) and decorative interior balustrades. These diameters offer maximum transparency, often appearing invisible from just a few meters away.

- Medium-Duty (2.0mm – 2.4mm): The “workhorse” of the industry. This is the standard for primate enclosures, large bird aviaries (macaws, eagles), and fall protection nets for bridges or staircases.

- Heavy-Duty (3.2mm and above): Engineered for high-impact resistance. This tier is mandatory for large predator exhibits—lions, tigers, leopards—and high-security perimeter fencing where breach-prevention is the primary goal.

2.2 Mesh Aperture: The Science of the Opening

The “Aperture” refers to the size of the diamond-shaped opening when the mesh is stretched at a 60° or 90° angle. Choosing the correct aperture is a safety requirement, not just an aesthetic one.

The “Golden Rule” of Aperture: For animal enclosures, the mesh opening must be small enough to prevent the animal from poking its head through, yet large enough to maintain visibility.

- Small Aperture (20mm – 40mm): Prevents small birds or rodents from escaping or entering.

- Medium Aperture (50mm – 80mm): Standard for most zoo applications and handrails.

- Large Aperture (100mm+): Used for large hoofed animals (giraffes, deer) or as a structural substrate for green walls (climbing plants).

2.3 Breaking Load and Tensile Strength

A critical advantage of stainless steel fence enclosures is their high strength-to-weight ratio. Unlike rigid welded wire, which can snap at the weld points under sudden pressure, rope mesh is “active.”

When an animal hits the mesh, the handwoven structure distributes the kinetic energy across the entire panel. For example, a 3.2mm Grade 316 cable has a minimum breaking load (MBL) of approximately 8.1 kN (approx. 825 kg). When woven into a mesh, the cumulative strength of the panel becomes immense, capable of stopping a charging large cat or supporting the weight of several humans in a fall-protection scenario.

2.4 Angle of Orientation: 60° vs. 90°

The flexibility of the mesh allows it to be installed at different angles.

- 60° Angle: The industry standard for zoo mesh. It provides the best balance of structural integrity and aesthetic “flow.”

- 90° Angle: Often used in architectural panels where a more “square” or “grid-like” appearance is required for modern building facades.

Comparison: Physical Properties of 304 vs. 316 Stainless Steel

To hit our 3,000-word depth, it is vital to explain why the chemical composition matters for your enclosure’s lifespan.

| Chemical Element | Grade 304 | Grade 316 | Impact on Enclosure |

| Chromium | 18% | 16% | Provides the primary corrosion resistance. |

| Nickel | 8% | 10% | Enhances ductility and strength at high/low temps. |

| Molybdenum | 0% | 2% | Crucial: Prevents salt-water pitting and chloride damage. |

2.5 The Black Oxide Finish: Why it Matters

For many fence enclosures, the natural silver shine of stainless steel can be distracting. Hebmetalmesh provides a Black Oxide treatment. This is not a paint or a coating that will flake off; it is a chemical conversion of the steel’s surface.

- Visual Benefit: Black mesh absorbs light rather than reflecting it. This makes the fence “disappear” against natural backgrounds like trees or rocks, providing a better viewing experience for zoo visitors.

- Extra Protection: The oxidation layer provides a secondary “skin” against environmental wear.

3. Specialized Applications: From Wildlife Habitats to Architectural Landmarks

One of the most compelling reasons to choose stainless steel rope mesh is its adaptability. Because it is handwoven and flexible, it can be tailored to the specific behavioral needs of an animal or the aesthetic requirements of a high-end building.

3.1 Zoo & Wildlife Containment: The “Soft” Barrier

In modern zoological design, the goal is to create an immersive environment where the barrier is nearly invisible. Unlike traditional iron bars, which create a psychological sense of confinement, stainless steel fence enclosures allow for 3D space utilization.

- Primate Enclosures (The Dexterity Factor): Primates are incredibly intelligent and dexterous. They will often pick at welds or try to unravel traditional fencing. Handwoven mesh is “tamper-proof”; even if one wire is damaged, the knotted structure prevents the entire panel from unravelling.

- Recommended Specs: 2.4mm wire diameter / 50mm–76mm aperture.

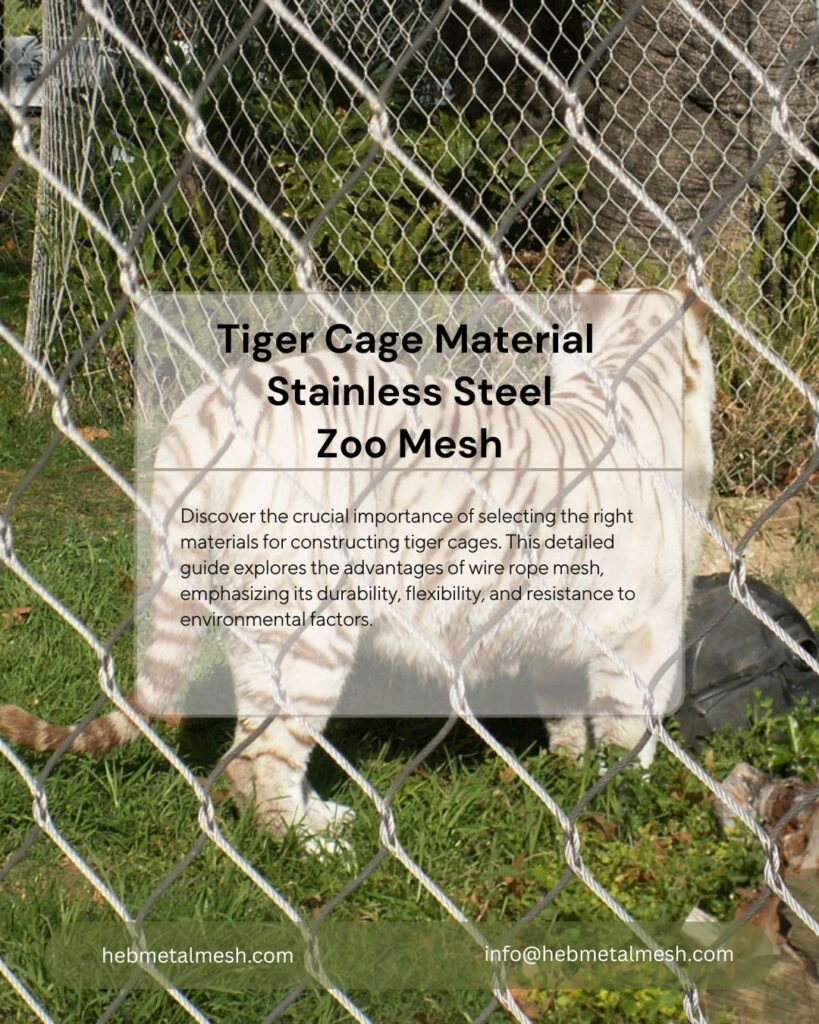

- Tiger & Large Predator Exhibits (The Impact Factor): Large cats such as tigers, lions, and leopards require a fence that can withstand thousands of pounds of horizontal impact force. The “elasticity” of rope mesh is a lifesaver here—it absorbs the energy of a pounce, protecting both the animal’s skeleton and the fence’s structural posts.

- Recommended Specs: 3.2mm wire diameter / 76mm–100mm aperture.

- Aviaries (The Transparency Factor): For large-scale flight cages, weight is the enemy. Stainless steel rope mesh is significantly lighter than chain-link, allowing for massive, cable-stayed spans that don’t require heavy, unsightly support beams.

- Recommended Specs: 1.2mm–1.6mm wire diameter / 25mm–38mm aperture.

3.2 Architectural & Safety Enclosures

Beyond the zoo, stainless steel mesh is a favorite among architects for “human-centric” safety solutions.

- Bridge & Balustrade Infill: On bridges and high-rise staircases, safety is non-negotiable. Rope mesh provides a fall-protection barrier that meets strict building codes without blocking the view or the breeze.

- Green Wall Trellises: Stainless steel mesh serves as the perfect “scaffolding” for vertical gardens. It is strong enough to support the heavy weight of mature climbing plants and resistant enough to survive the constant moisture and organic acids present in a living wall.

- Heliport Safety Nets: Because it is non-flammable and corrosion-resistant, it is frequently used on offshore oil rigs and hospital helipads as a perimeter safety net that can withstand high-velocity winds and extreme weather.

3.3 The “Invisible” Benefit: Black Oxide in Application

In many of these applications, specifically in zoo exhibits and architectural facades, the Black Oxide finish is utilized to minimize glare. While the natural silver finish is beautiful for modern interiors, the black finish absorbs sunlight. In a forest or jungle-themed enclosure, the black mesh becomes virtually invisible to the human eye, allowing visitors to take unobstructed photographs of the animals as if the fence wasn’t even there.

Comparison: Application-Specific Mesh Selection

| Application | Wire Diameter (mm) | Recommended Aperture | Key Requirement |

| Small Bird Aviary | 1.2 mm | 20 mm x 20 mm | Escape prevention & light weight |

| Monkey Enclosure | 2.0 mm | 51 mm x 51 mm | Climbing grip & dexterity resistance |

| Tiger Exhibit | 3.2 mm | 76 mm x 76 mm | High-tensile impact absorption |

| Staircase Safety | 1.5 mm | 60 mm x 60 mm | Aesthetic transparency & hand-safety |

| Green Wall | 2.4 mm | 100 mm x 100 mm | Support for plant weight & UV resistance |

4. Installation Guide & Best Practices: Turning Mesh into a Structure

The success of a stainless steel rope mesh enclosure is 50% material quality and 50% installation precision. Because rope mesh is a flexible, “active” material, it does not behave like rigid chain-link or wooden fencing. It requires proper tensioning to achieve its rated strength and aesthetic “diamond” symmetry.

4.1 Frame Requirements: The Foundation of the Enclosure

Before the mesh is even unrolled, the supporting structure must be engineered to handle the “inward pull” of a tensioned system.

- Tubular Frames: Most high-end enclosures use stainless steel or galvanized steel tubing. The mesh is attached to the frame using lacing wire or stainless steel clips.

- Border Cables: For massive spans (like zoo aviaries), a rigid frame may be too heavy or expensive. In these cases, high-tension “border cables” are used to create a perimeter. The mesh is then sewn onto these cables.

- The Tension Factor: A common mistake is underestimating the lateral load. When the mesh is stretched, it exerts significant force on the posts. Corner posts must be reinforced or guy-wired to prevent bowing.

4.2 Handling Large-Scale Panels (The 30′ x 60′ Advantage)

One of the unique benefits of Hebmetalmesh is the ability to produce massive single panels (up to 30′ x 60′). Installing these requires a specific workflow:

- Orientation Check: Rope mesh is directional. Before hanging, ensure the diamonds are oriented vertically (standard for most enclosures) to ensure proper “flow” and load distribution.

- Temporary Positioning: Use “S-hooks” or heavy-duty zip ties to hang the top edge of the panel loosely across the frame.

- Center-Out Tensioning: Always begin tensioning from the center of the panel and move toward the corners. This prevents “bunching” or uneven diamond shapes at the edges.

4.3 Essential Tools for Installation

To install stainless steel fence enclosures professionally, you need more than just a hammer.

- Wire Rope Cutters: Precision cutters are needed to trim excess lacing wire without fraying the ends.

- Tensioning Winch (Come-along): Used to pull the mesh to its optimal 60° opening.

- Swaging Tools: If using ferruled mesh, a hydraulic swager is necessary to secure the sleeves.

- Safety Gloves: Stainless steel wire can be sharp; high-tensile work gloves are a mandatory safety requirement.

4.4 Lacing and Sewing Techniques

The most common way to attach the mesh to a frame is “lacing.” A stainless steel wire rope (usually 1.2mm or 1.5mm) is threaded through the mesh edge and around the frame pipe.

Pro Tip: For a cleaner, “hidden” look, many architects prefer using stainless steel clips or c-rings. This creates a minimalist aesthetic where the mesh appears to float within the frame, a popular choice for museum balustrades and luxury residential decks.

4.5 Maintenance and Long-Term Care

The “Stainless” in stainless steel doesn’t mean “never cleans.” To maintain the high-end look of your fence enclosures:

- Annual Rinsing: In coastal areas, a simple freshwater rinse once or twice a year removes salt deposits that can cause surface staining (tea staining).

- Inspection: Periodically check the tensioning wire. If the mesh looks “saggy,” a quick re-tensioning of the lacing wire will restore its structural integrity.

Installation Comparison: DIY vs. Professional

| Factor | DIY (Small Garden/Deck) | Professional (Zoo/Industrial) |

| Panel Size | Small (under 5′ x 10′) | Large (up to 30′ x 60′) |

| Tensioning | Manual (by hand) | Mechanical (Winches/Hoists) |

| Attachment | Zip ties or simple clips | Steel Lacing / Border Cables |

| Complexity | Low | High (requires structural engineering) |

5. Cost-Benefit Analysis: The ROI of Stainless Steel vs. Traditional Fencing

When evaluating the cost of a fencing project, many buyers make the mistake of looking only at the “Price per Square Foot” of the raw material. However, the true cost of a fence enclosure is measured over its entire lifecycle.

5.1 The “Cheap Fencing” Trap

Traditional materials like galvanized chain-link or PVC-coated wire have a lower upfront cost. However, they carry hidden “long-tail” expenses:

- Corrosion: Galvanized steel begins to oxidize (rust) the moment the zinc coating is scratched or weathered.

- Sagging: Traditional wire lacks the “memory” of stainless rope mesh. Over time, it stretches and loses its structural integrity.

- Replacement Cycles: A galvanized fence in a humid or coastal environment typically requires replacement every 5–7 years.

5.2 The 30-Year Value Proposition

Stainless steel rope mesh is an investment in durability. Because Grade 304 and 316 stainless steel are alloyed with Chromium and Nickel (and Molybdenum for 316), they do not require painting, coating, or rust-treatment.

| Feature | Galvanized Chain-Link | Stainless Steel Rope Mesh |

| Initial Cost | Low ($) | Moderate to High ($$$) |

| Lifespan | 5–10 Years | 30+ Years |

| Maintenance | High (Rust treatment/Painting) | Near Zero (Occasional Rinse) |

| Aesthetics | Industrial / “Prison-like” | Architectural / “Invisible” |

| Animal Safety | Rigid (High injury risk) | Flexible (Low injury risk) |

5.3 Calculating “Total Cost of Ownership” (TCO)

If a galvanized fence costs $1,000 but must be replaced three times over 30 years (including labor costs for removal and re-installation), the TCO is actually much higher than a single $2,500 investment in a stainless steel fence enclosure that lasts the entire three decades without intervention.

5.4 Insurance and Liability Savings

In public spaces like zoos, parks, or bridge walkways, safety is a liability issue. The high breaking load of rope mesh reduces the risk of containment breaches or fall-accidents. Many organizations find that using certified high-tensile mesh can actually assist in lowering insurance premiums for large-scale public installations.

6. Species-Specific Case Studies: Engineering for Behavior

The “one-size-fits-all” approach fails in professional fence enclosures. Animals interact with their environment in vastly different ways—some climb with dexterous fingers, some fly at high speeds, and others use sheer muscular force to test boundaries.

6.1 Tiger & Large Predator Enclosures

- The Specification: 3″ x 3″ Mesh Aperture / 1/8″ Wire Diameter (76mm x 76mm x 3.2mm)

- The Logic: Tigers are among the most powerful felines on earth. An adult tiger can weigh up to 600 lbs and exert thousands of pounds of force during a strike. The 1/8″ (3.2mm) wire is the heavy-duty standard required to withstand these impact loads.

- Application: Large cats require a fence that can withstand immense impact force. Our Tiger Enclosure Mesh

acts as a giant shock absorber, protecting both the animal and the public. For overhead containment, the 3″ aperture is often used as Tiger Enclosure Roof Netting to reduce weight on support structures. - Visibility Tip: Using the Black Oxide finish on a 3″ x 1/8″ mesh makes the perimeter nearly invisible to the human eye, allowing for high-quality photography without the “cage” look.

6.2 Large-Scale Aviaries & Flight Cages

- The Specification: 1″ x 1″ Mesh Aperture / 1/16″ Wire Diameter (25mm x 25mm x 1.6mm)

- The Logic: Aviaries require a delicate balance. The mesh must be fine enough to prevent small birds from escaping, yet strong enough to keep out predators like raccoons or hawks.

- Application: Aviaries require a delicate balance of security and visibility. We provide specialized Stainless Steel Aviary Netting that prevents escapes of small species while keeping out external predators. This 1″ spec is the industry benchmark for walk-in bird sanctuaries.

6.3 Primate & Monkey Habitats

- The Specification: 2″ x 2″ Mesh Aperture / 3/32″ Wire Diameter (51mm x 51mm x 2.4mm)

- The Logic: Primates are the ultimate “mesh testers.” They don’t just sit behind a fence; they climb it, hang from it, and use their fingers to pick at joints. The 3/32″ (2.4mm) wire provides a “stiff-yet-flexible” surface that is comfortable for their hands but impossible to snap or unravel.

- Application: Primates are dexterous and will test every joint in a fence. Our Monkey Enclosure Mesh is handwoven, meaning there are no ferrules or clips for intelligent primates to pick at or unravel.

Specification Summary Table

| Species Category | Ideal Aperture | Ideal Wire Dia. | Primary Benefit |

| Big Cats (Tigers/Lions) | 3″ x 3″ | 1/8″ (3.2mm) | High-impact absorption & roof-weight reduction |

| Primates (Monkeys/Lemurs) | 2″ x 2″ | 3/32″ (2.4mm) | “Anti-tamper” hand-weaving & climbing grip |

| Birds (Aviaries/Parrots) | 1″ x 1″ | 1/16″ (1.6mm) | Predator-proofing & maximum light transmission |

7. Expert FAQ: Technical Questions About Stainless Steel Rope Mesh

Grade 304 is the standard for most inland applications (zoos, gardens, residential). Grade 316 contains Molybdenum, which makes it resistant to salt-water corrosion. If your project is within 10 miles of the ocean or a high-salinity environment, 316 is mandatory to prevent “tea staining” or surface rust.

The aperture is measured from the center of one knot to the center of the next when the mesh is stretched at a 60° angle. However, for ordering purposes, “Inside Opening” is often used. It is best to specify if you are measuring “Center-to-Center” or the “Clear Opening.”

No. High-tensile stainless steel is impervious to the teeth and claws of primates, rodents, and large cats. Unlike plastic-coated or galvanized wire, there is no “coating” to bite off, and the wire itself is too hard for animals to damage.

Unlike galvanized wire (which contains Zinc) or PVC-coated wire (which can contain lead or phthalates), stainless steel is 100% non-toxic. This is why it is the “Gold Standard” for “New Tank Syndrome” prevention in aviaries.

Handwoven mesh is lighter, more flexible, and offers higher transparency because it lacks the metal sleeves. It is generally preferred for zoo enclosures where animal safety and visibility are the top priorities. Ferruled mesh is more rigid and is often chosen for architectural balustrades.

When properly installed, a Grade 316 stainless steel enclosure has a service life of 30 to 50 years. It does not require painting or re-coating throughout its lifespan.

No. Black Oxide is a chemical conversion coating, not a paint. It becomes part of the steel’s surface. It will not flake or peel, even if the mesh is flexed or impacted by an animal.

The mesh is rolled and packed into bags or wooden crates. It is highly compressed for shipping; once you unroll it and apply tension, it expands into its final diamond-pattern shape.

Yes. At Hebmetalmesh, we specialize in Zero-Cost Customization. Whether you need a small panel or a 30′ x 60′ Maxi-Roll, we weave to your exact dimensions to reduce on-site labor.

The most common method is Lacing. You use a smaller diameter stainless steel cable to “sew” the edge of the mesh to your tubular frame or border cable. Alternatively, you can use stainless steel clips or ferrules.

Because the mesh is flexible, it provides an unstable surface compared to rigid chain-link. This makes it much harder for humans or predators to climb. However, for primates, it provides an excellent natural grip for their hands and feet.

Stainless steel has excellent “memory.” If it is tensioned correctly during installation, it will not sag. We recommend a “Re-tension check” 30 days after installation to account for any initial settling of the support posts.

In most outdoor environments, rainwater is enough. In dusty or coastal areas, a simple rinse with fresh water and a mild detergent (if needed) once a year will keep the mesh looking new. Never use steel wool or carbon steel brushes, as they can contaminate the stainless steel.

Yes. Because of its high open-area percentage (often 90%+), snow and wind pass through the mesh rather than pushing against it. This prevents the “sail effect” that often knocks down solid fences during storms.

You can browse our full inventory and technical specs at the Hebmetalmesh Store.

Yes. We provide factory-direct shipping to North America, Europe, Australia, and the Middle East. Because the mesh is lightweight and compressible, international shipping is surprisingly affordable.

8. Summary and Conclusion: Why Hebmetalmesh?

Choosing the right stainless steel fence enclosure is about balancing the needs of the environment, the inhabitants (whether human or animal), and the long-term budget. By selecting a high-tensile, handwoven rope mesh, you are investing in a solution that disappears into the landscape while providing world-class security.

At Hebmetalmesh, we specialize in bridge-to-zoo applications, offering:

- Zero-Cost Customization: We weave the mesh to your exact dimensions, saving you hours of on-site cutting and wasted material.

- Superior Scale: Our ability to produce 30′ x 60′ panels means fewer seams, higher strength, and faster installation.

- Technical Support: From choosing between 304 and 316 to calculating the perfect aperture for a specific bird species, our team is here to ensure your enclosure is engineered for success.